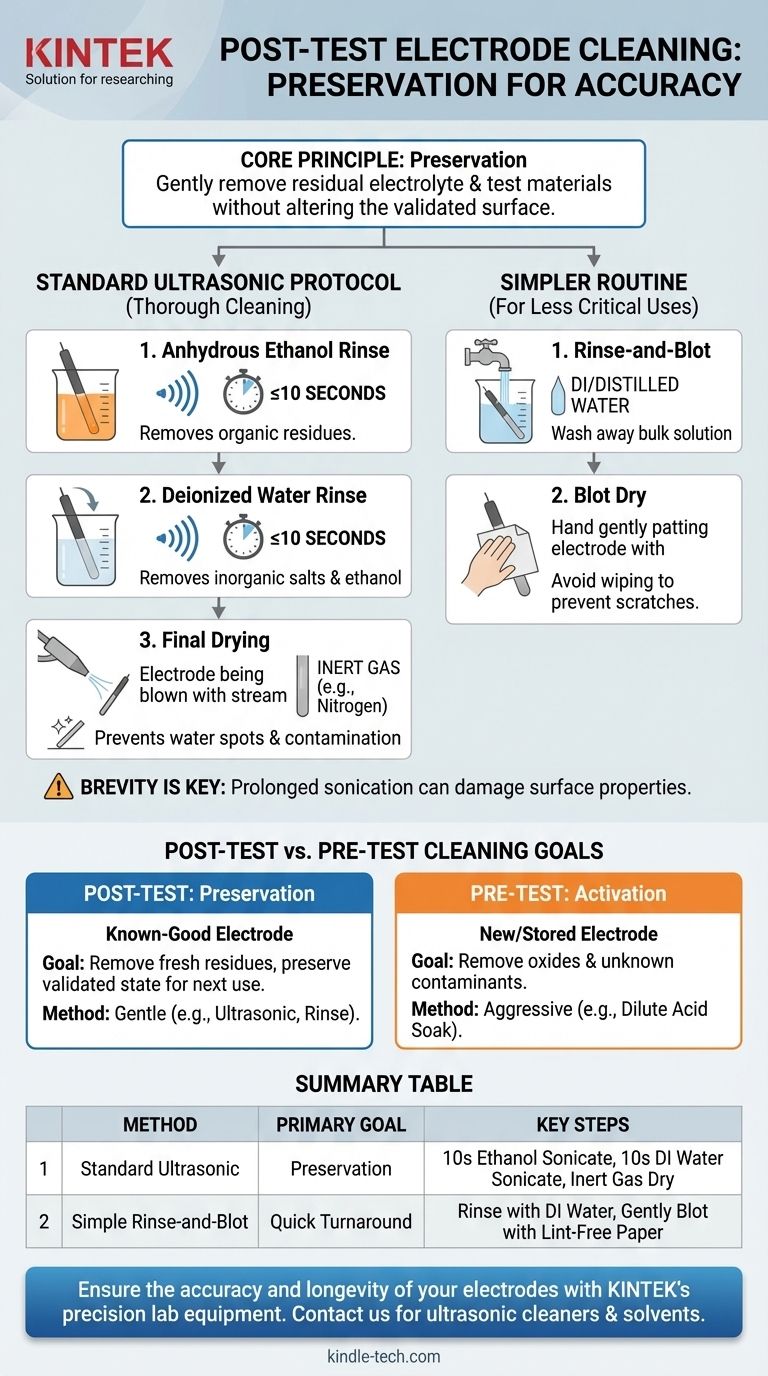

For an electrode that has passed testing, the standard cleaning procedure is a two-step ultrasonic process. This involves brief sonication (no more than 10 seconds) first in anhydrous ethanol to remove organic residues, followed by another brief sonication in deionized water to remove inorganic salts and the ethanol itself, before being blown dry for storage.

The core principle of post-test cleaning is preservation. The goal is to gently remove residual electrolyte and test materials without altering the electrode's calibrated surface, ensuring it remains in a known, acceptable state for immediate reuse or proper storage.

The Standard Post-Test Ultrasonic Protocol

This method is the most thorough procedure for cleaning a validated electrode, ensuring it is free of contaminants before storage.

Step 1: Anhydrous Ethanol Rinse

The first step involves immersing the electrode in a beaker of anhydrous ethanol and sonicating. Ethanol is an effective solvent for a wide range of organic compounds that may have been part of the electrolyte or test solution.

Step 2: Deionized Water Rinse

Immediately after the ethanol bath, the electrode is moved to a second beaker containing deionized (DI) water for another brief sonication. This step serves to remove any inorganic salts and rinse away the residual ethanol from the surface.

The Importance of Brevity (≤10 Seconds)

The sonication time in each solution must not exceed 10 seconds. Prolonged exposure to ultrasonic energy can cause microscopic physical damage to the delicate electrode surface, altering its electrochemical properties and compromising future measurements.

Final Drying and Storage

After the final rinse, the electrode should be removed and carefully blown dry with clean, inert gas like nitrogen or air. This prevents water spots and contamination. Once completely dry, it is ready for storage or the next use.

A Simpler Method for Routine Rinsing

For less critical applications or when an ultrasonic bath is unavailable, a simpler manual rinse can be performed.

The Rinse-and-Blot Technique

Promptly remove the electrode from the electrolyte after use. Rinse it thoroughly with distilled or deionized water to wash away the bulk of the testing solution.

After rinsing, gently absorb the remaining moisture from the surface using lint-free filter paper. Avoid wiping, as this can scratch the surface or leave behind fibers.

Understanding the Trade-offs: Post-Test vs. Pre-Test Cleaning

The cleaning method you choose depends entirely on the state of the electrode and your goal. The procedure for a known-good electrode is fundamentally different from one being prepared for use after long storage.

Post-Test Goal: Preservation

After a successful test, the electrode is in a known, good condition. Cleaning is gentle and aims only to remove fresh residues. The primary goal is to preserve the validated surface for the next experiment.

Pre-Test Goal: Activation

Cleaning an electrode before its first use or after prolonged storage is often more aggressive. Procedures like soaking in dilute acid are designed to remove oxides or unknown contaminants that may have formed over time. This "activation" step ensures the surface is electrochemically active and ready for accurate measurement.

Avoiding Chemical Damage

If you encounter stubborn stains, you may use a targeted cleaning agent. However, you must ensure the cleaner is not corrosive to the electrode material (e.g., platinum). Aggressive chemicals can permanently damage the electrode.

Making the Right Choice for Your Goal

Select your cleaning method based on the electrode's recent use and your immediate objective.

- If your primary focus is removing organic residues: The two-step ultrasonic method with ethanol is the most effective procedure.

- If your primary focus is a quick turnaround between simple aqueous tests: A thorough rinse with DI water and a careful blot-dry may be sufficient.

- If your primary focus is preparing an electrode for long-term storage: The full ultrasonic procedure is the best practice to prevent degradation.

- If your primary focus is preparing a stored electrode for a new test: Consider a more aggressive pre-treatment, such as a dilute acid wash, to activate the surface.

Proper cleaning is not just maintenance; it is the foundation of reliable and repeatable electrochemical measurements.

Summary Table:

| Cleaning Method | Primary Goal | Key Steps |

|---|---|---|

| Standard Ultrasonic | Preservation & Thorough Cleaning | 1. 10s sonication in anhydrous ethanol 2. 10s sonication in DI water 3. Blow dry with inert gas |

| Simple Rinse-and-Blot | Quick Turnaround | 1. Rinse with DI water 2. Gently blot dry with lint-free paper |

Ensure the accuracy and longevity of your electrodes with KINTEK's precision lab equipment.

Proper cleaning is crucial for reliable results. KINTEK specializes in the ultrasonic cleaners, pure solvents, and inert gases needed to execute these protocols effectively. Our products are designed to meet the exacting standards of electrochemical research, helping you preserve your electrode investment and maintain data integrity.

Contact our experts today to find the ideal cleaning and storage solutions for your laboratory's specific needs.

Visual Guide

Related Products

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

- Laboratory Sterilizer Lab Autoclave Vertical Pressure Steam Sterilizer for Liquid Crystal Display Automatic Type

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- Laboratory Test Sieves and Sieving Machines

- Benchtop Laboratory Vacuum Freeze Dryer

People Also Ask

- Why is it important to autoclave the prepared reagents before using? Ensure Sterility and Reliable Results

- Do you need to autoclave glassware? A Guide to Sterilization vs. Cleaning

- Can autoclave sterilize liquid? Master Safe and Effective Liquid Sterilization

- What is the use of autoclave in medical? The Critical Role of Sterilization in Patient Safety

- What are the advantages of autoclaving in hospitals? Achieve Unmatched Sterilization for Patient Safety