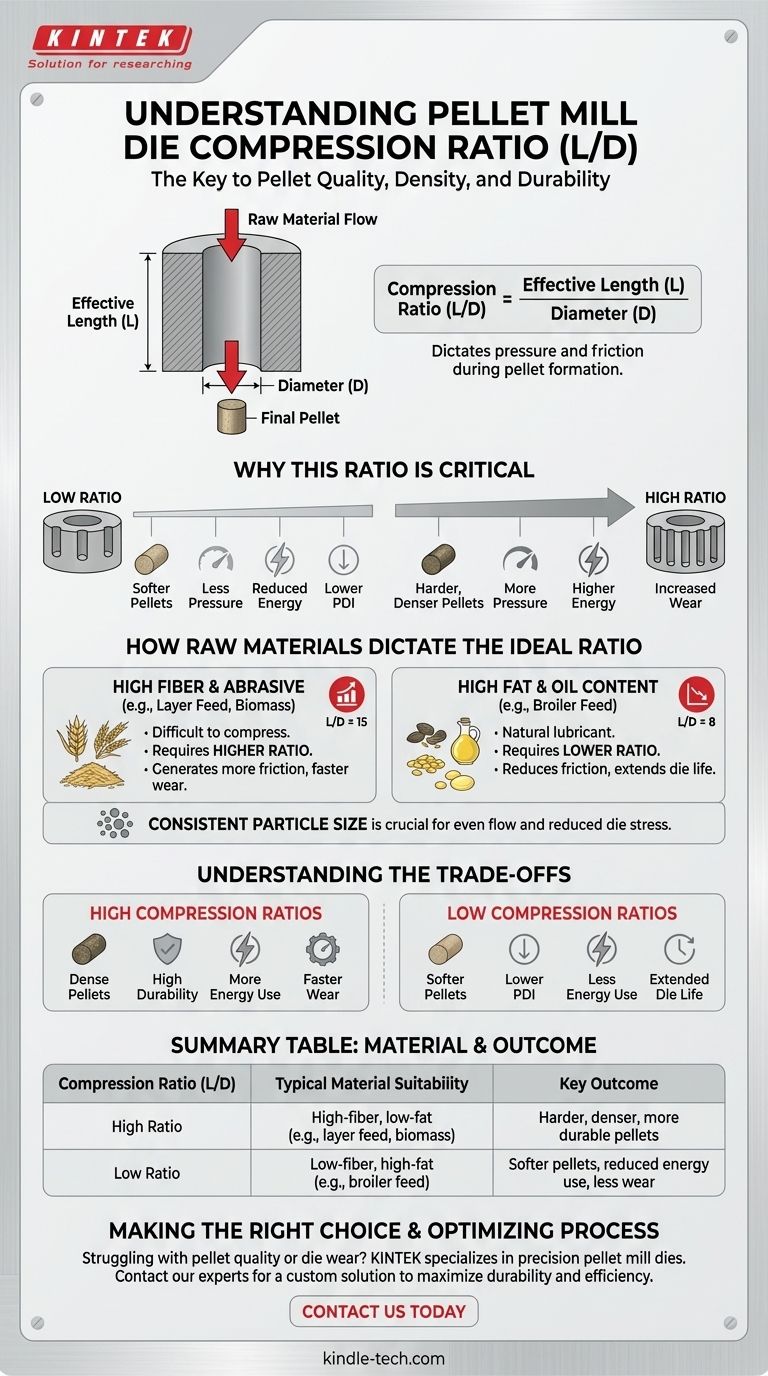

In simple terms, the compression ratio of a pellet mill die is the ratio of the effective length of the die hole to its diameter. This single parameter is one of the most critical factors in determining the final quality, density, and durability of the pellets produced. It dictates how much pressure and friction the raw material is subjected to as it is forced through the die.

The compression ratio isn't a fixed property of a pellet mill itself, but rather a key design specification of the die. The ideal ratio must be carefully selected based on the specific characteristics of the raw material being processed to achieve optimal pellet quality and production efficiency.

Understanding the Core Concept

A pellet mill die is more than just a piece of metal with holes in it; it's a precision tool designed to apply immense pressure. The compression ratio is the primary language used to define how that pressure is applied.

The Defining Formula (L/D Ratio)

The compression ratio is often referred to as the L/D ratio.

It is calculated by dividing the effective length (L) of the die hole by the hole's diameter (D). The "effective length" is the portion of the hole where the primary compression and pellet formation actually occur.

Why This Ratio is Critical

The L/D ratio directly controls the pelleting process. A higher ratio means the material spends more time under greater pressure and friction within the die hole. This typically results in a harder, denser, and more durable pellet.

Conversely, a lower ratio means less time under compression, which is easier on the machine but may produce softer pellets that are more prone to breaking apart.

How Raw Materials Dictate the Ideal Ratio

There is no single "best" compression ratio. The correct choice is entirely dependent on the feed formulation being processed, as different ingredients behave differently under pressure.

The Impact of Fiber and Abrasiveness

Materials with high fiber content, such as layer hen feed, are naturally difficult to compress and bind together. They require a higher compression ratio to generate the necessary heat and pressure to form a durable pellet.

These abrasive materials create more frictional load, which also leads to faster wear and a shorter operational life for the die.

The Role of Fats and Oils

Feeds with a higher fat or oil content, like many broiler chicken formulations, behave very differently. The oil acts as a natural lubricant, reducing the friction as the material passes through the die.

Because of this lubrication, a lower compression ratio is often sufficient. Using a ratio that is too high can actually hinder production, as the material may slip through too easily without proper compaction.

The Importance of Consistent Particle Size

The physical characteristics of the mash before it enters the die are crucial. A mash with a consistent and appropriate particle size allows for even flow and uniform compression.

Uneven or oversized particles create unnecessary stress on the die and result in inconsistent pellet quality. A die processing consistently sized mash will always have a longer, more predictable service life.

Understanding the Trade-offs

Selecting a compression ratio involves balancing pellet quality with production efficiency and equipment longevity.

High Compression Ratios: Benefits and Downsides

A high L/D ratio is excellent for creating very dense, durable pellets from difficult materials. However, it requires more energy, increases the operational temperature, and accelerates wear on both the die and the roller shells.

Low Compression Ratios: Benefits and Downsides

A low L/D ratio reduces energy consumption and mechanical stress, extending the life of your equipment. The risk is producing pellets that are too soft or have a low Pellet Durability Index (PDI), leading to excess fines or dust.

Factors Beyond the Ratio

While the compression ratio is critical, overall performance also depends on other factors. Proper machine maintenance, skilled operator oversight, and consistent conditioning (managing moisture and temperature) of the incoming mash are essential for achieving quality results and maximizing the life of the die.

Making the Right Choice for Your Goal

The goal is to match the die's compression ratio to the specific requirements of your feed formulation.

- If your primary focus is high-fiber, low-fat materials (e.g., layer feed, biomass): You will likely need a die with a higher compression ratio to ensure sufficient compaction and durability.

- If your primary focus is low-fiber, high-fat materials (e.g., broiler feed): A die with a lower compression ratio is generally more effective, leveraging the natural lubrication of the ingredients.

- If your primary focus is extending die life: Ensure your mash has a consistent particle size and that operators perform regular maintenance and cleaning, as these factors have a major impact on wear.

Ultimately, selecting the correct compression ratio is the key to transforming raw ingredients into a high-quality, durable final product.

Summary Table:

| Compression Ratio (L/D) | Typical Material Suitability | Key Outcome |

|---|---|---|

| High Ratio | High-fiber, low-fat (e.g., layer feed, biomass) | Harder, denser, more durable pellets |

| Low Ratio | Low-fiber, high-fat (e.g., broiler feed) | Softer pellets, reduced energy use, less wear |

Struggling with pellet quality or die wear? The right compression ratio is critical for your specific feed formulation. KINTEK specializes in lab equipment and consumables, including precision pellet mill dies designed to maximize your pellet durability and production efficiency. Our experts can help you select the perfect die for your materials. Contact us today to optimize your pelleting process and achieve superior results!

Get a Custom Solution & Contact Our Experts

Visual Guide

Related Products

- Special Heat Press Mold for Lab Use

- Open Type Two Roll Mixing Mill Machine for Rubber Crusher

- High Energy Vibratory Laboratory Ball Mill Double Tank Type

- Button Battery Tablet Press Sealing Mold for Lab Use

- Assemble Square Lab Press Mold for Laboratory Applications

People Also Ask

- How do custom graphite molds contribute to Al-20% Si/graphite flake composites? Optimize Microstructure & Conductivity

- What are the primary functions of high-density graphite molds in FAST/SPS? Optimizing Thermal and Mechanical Performance

- What are the advantages of using high-strength graphite molds in the hot press sintering of Ti6Al4V-based composites?

- What role do high-strength graphite molds play during vacuum hot pressing? Enhance Precision in CuAlMn Composites

- Why are custom pressure molds used during the hot pressing process for solid polymer electrolytes?