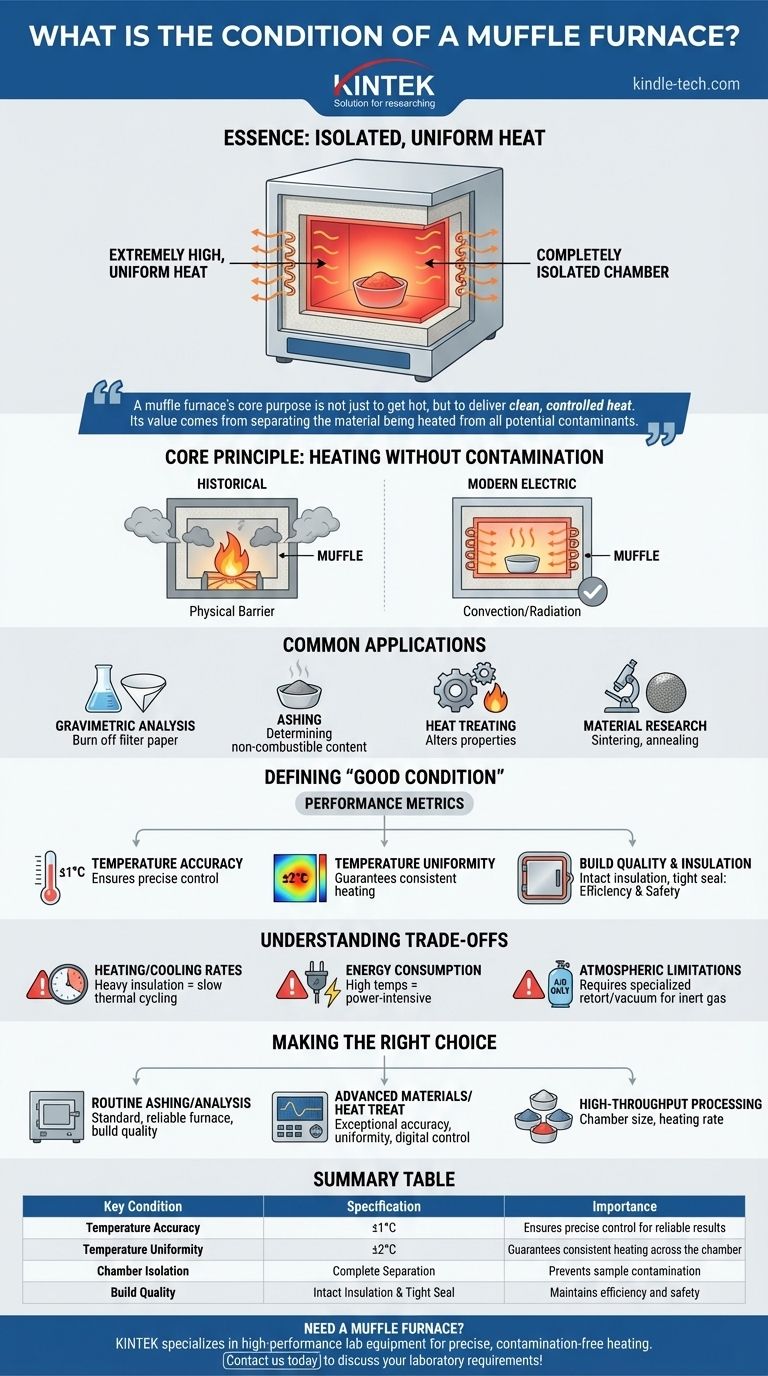

In essence, the defining condition of a muffle furnace is its ability to provide extremely high, uniform heat within a completely isolated chamber. It is a type of laboratory oven designed to heat materials without exposing them to the flame and combustion byproducts of a fuel source or even the direct radiation from electric heating elements. This ensures the purity of the sample during processes like chemical analysis, material testing, and heat treatment.

A muffle furnace's core purpose is not just to get hot, but to deliver clean, controlled heat. Its value comes from separating the material being heated from all potential contaminants, ensuring the process is pure and the results are reliable.

The Core Principle: Heating Without Contamination

A muffle furnace solves a fundamental problem in high-temperature work: how to heat a substance without changing its chemical composition from external influences.

What is the "Muffle"?

The term "muffle" refers to the insulating chamber that separates the sample from the heat source. Historically, in furnaces fueled by coal or wood, this was a physical barrier that kept ash and combustion gases from touching the material.

In modern electric furnaces, the "muffle" is the insulated inner chamber. The heating coils are typically embedded within the chamber walls. This design heats the sample through convection and radiation within the chamber, preventing any direct contact with the electric elements.

Common Applications

The ability to provide clean heat makes muffle furnaces essential for a range of precise applications, including:

- Gravimetric Analysis: Burning off filter paper to leave only a non-combustible residue (ash) for weighing.

- Ashing: Determining the non-combustible content of samples like food, plastics, or coal.

- Heat Treating: Altering the physical and chemical properties of metals and ceramics through controlled heating and cooling cycles.

- Material Research: Sintering, annealing, or melting materials in a controlled environment.

Defining a "Good Condition" Furnace

The "condition" of a muffle furnace can be evaluated by its performance metrics, which are critical for achieving reliable and repeatable results in the lab.

Temperature Accuracy

This refers to how closely the temperature displayed on the controller matches the actual temperature inside the chamber. A high-quality furnace in good condition should have an accuracy of ±1°C.

Temperature Uniformity

This measures the temperature consistency across different points within the chamber. Poor uniformity can lead to inconsistent results, especially when processing multiple samples. A high-performance furnace should maintain a uniformity of ±2°C.

Build Quality and Insulation

The physical condition of the furnace is paramount. The insulating material must be intact to maintain efficiency and prevent heat loss. The door seal must be tight to ensure a stable internal atmosphere and for user safety.

Understanding the Trade-offs

While incredibly useful, muffle furnaces have operational characteristics that you must consider. Understanding these limitations is key to using them effectively.

Heating and Cooling Rates

The same heavy insulation that allows a muffle furnace to reach and hold high temperatures also means it heats up and cools down relatively slowly. They are not designed for processes requiring rapid thermal cycling.

Energy Consumption

Reaching temperatures of 1000°C or higher requires a significant amount of electrical energy. In a laboratory setting, they are often one of the more power-intensive pieces of equipment.

Atmospheric Limitations

A standard muffle furnace operates under normal atmospheric air. If your process requires a vacuum or an inert gas atmosphere (like argon or nitrogen) to prevent oxidation, you will need a specialized retort or vacuum furnace, not a standard muffle furnace.

Making the Right Choice for Your Goal

Selecting or evaluating a muffle furnace depends entirely on the specific requirements of your work.

- If your primary focus is routine ashing or basic analysis: A standard, reliable muffle furnace with good build quality will suffice; extreme temperature uniformity may not be critical.

- If your primary focus is advanced materials science or precise heat treating: Prioritize a furnace with exceptional temperature accuracy and uniformity, backed by a sophisticated digital controller.

- If your primary focus is high-throughput sample processing: Consider the chamber size and the furnace's heating rate to ensure it can meet your lab's workflow demands.

Ultimately, the right muffle furnace is one whose condition and performance specifications align perfectly with the precision your application demands.

Summary Table:

| Key Condition | Specification | Importance |

|---|---|---|

| Temperature Accuracy | ±1°C | Ensures precise control for reliable results |

| Temperature Uniformity | ±2°C | Guarantees consistent heating across the chamber |

| Chamber Isolation | Complete separation from heat source | Prevents sample contamination |

| Build Quality | Intact insulation & tight door seal | Maintains efficiency and safety |

Need a muffle furnace that delivers precise, contamination-free heating? KINTEK specializes in high-performance lab equipment, including muffle furnaces designed for accuracy and reliability in applications like ashing, heat treatment, and material testing. Our experts can help you select the right furnace for your specific needs. Contact us today to discuss your laboratory requirements and ensure your processes are built on a foundation of pure, controlled heat!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1700℃ Muffle Oven Furnace for Laboratory

- 1800℃ Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- How is heat transferred in a furnace? Master Radiation, Convection & Conduction

- What are the precautions for heat in the laboratory? Essential Safety Rules to Prevent Burns and Fires

- How do you clean a muffle furnace? A Step-by-Step Guide to Ensure Safety and Longevity

- What is the maintenance of laboratory equipment? Ensure Data Integrity and Extend Equipment Lifespan

- What is the burnout cycle on a furnace? Stop This Destructive Overheating Pattern Now