At its core, a furnace cooling system serves a dual purpose. It is not a single entity but a combination of subsystems designed to protect the furnace equipment from heat damage and to precisely control the temperature of the material being processed. This system uses circulating water to cool the furnace body and an inert gas to cool the product inside.

The cooling system is one of the most critical aspects of a modern industrial furnace. Its primary function is twofold: to safeguard the furnace as a high-value asset by preventing overheating, and to guarantee the quality and consistency of the final product through controlled cooling cycles.

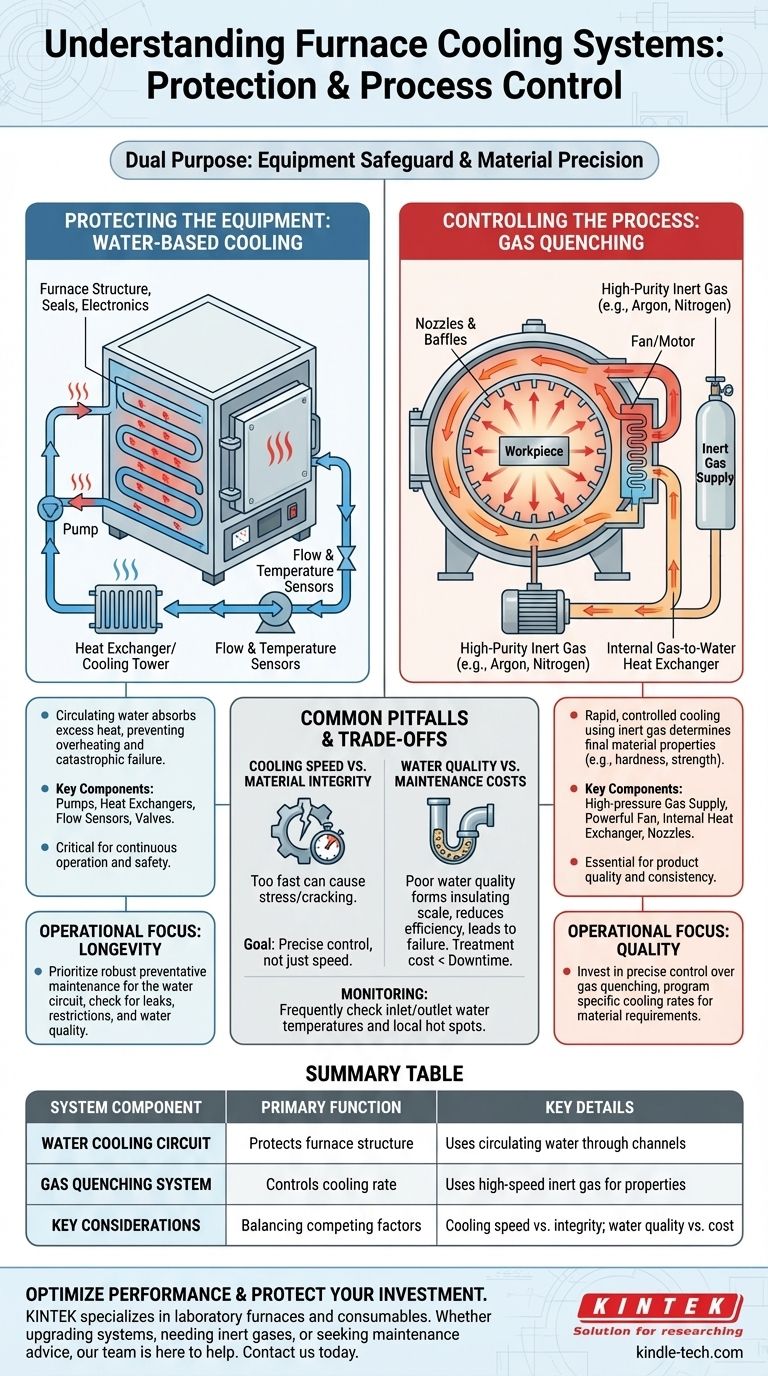

The Dual Role of a Furnace Cooling System

Understanding a furnace's cooling system requires separating its two primary responsibilities: protecting the machine itself and controlling the metallurgical process of the workpiece.

Protecting the Equipment: Water-Based Cooling

The immense heat generated within a furnace—often thousands of degrees—would quickly destroy the furnace structure, seals, and electronics without active cooling.

A network of channels and pipes is built into the furnace walls, door, and power supply components. Cooling water is constantly circulated through this network to absorb and carry away excess heat, much like a radiator in a car.

This process is critical for preventing the furnace from shutting down due to over-temperature alarms and, in a worst-case scenario, catastrophic failure like a vacuum leak or meltdown of critical components.

Controlling the Process: Gas Quenching

For the material being heat-treated inside (the "workpiece"), the cooling phase is just as important as the heating phase. The rate of cooling determines the final physical properties of the metal, such as hardness and strength.

In vacuum furnaces, this is achieved by flooding the heated chamber with a high-purity inert gas, such as argon or nitrogen. A powerful fan circulates this gas at high speed, rapidly and uniformly transferring heat away from the workpiece. This process is often called gas quenching.

Understanding the Key Components

Each function of the cooling system relies on a set of specialized components working in unison.

The Water Cooling Circuit

This circuit is the furnace's life-support system. It ensures that water flows consistently to all critical areas. Key parts include:

- Pumps to maintain water pressure and flow.

- Heat Exchangers (or cooling towers) to cool the water after it has absorbed heat from the furnace.

- Flow and Temperature Sensors to monitor the system's health and provide feedback to the control system.

- Valves to adjust and control water flow to different zones.

The Gas Quenching System

This system is designed for process precision. It must deliver rapid, controlled cooling to the workpiece. Its main components are:

- A high-pressure inert gas supply.

- A powerful motor and fan located inside the furnace to circulate the gas.

- An internal gas-to-water heat exchanger to cool the hot gas after it passes over the workpiece, preparing it for another cooling pass.

- Nozzles and baffles to direct the gas flow for maximum cooling uniformity.

Common Pitfalls and Trade-offs

Effective cooling management involves balancing competing factors. Misunderstanding these can lead to poor product quality or equipment damage.

Cooling Speed vs. Material Integrity

While rapid cooling is often desired, a cooling rate that is too fast can introduce internal stresses, distortion, or even cracking in the workpiece. The goal is precise control, not just maximum speed. The cooling cycle must be engineered for the specific material and geometry of the part.

Water Quality vs. Maintenance Costs

Using untreated or poor-quality water in the cooling circuit is a common but costly mistake. Minerals in the water can precipitate and form an insulating scale inside the cooling channels, drastically reducing cooling efficiency.

This forces the system to work harder and can eventually lead to a complete blockage, starving a critical component of coolant and causing a major failure. The initial cost of a water treatment system is almost always lower than the cost of downtime and repair.

Monitoring and Early Detection

Failure to actively monitor the cooling system is a significant risk. Operators should frequently check:

- Inlet and outlet water temperatures: A large difference indicates high heat load and proper function, but a growing difference can signal reduced water flow.

- Local hot spots: Physically touching (with caution) electrode connectors, furnace doors, and transformer lines can reveal areas where cooling has become ineffective, providing an early warning before a sensor alarm.

Applying This to Your Operation

Your operational priority will determine which aspect of the cooling system demands the most attention.

- If your primary focus is equipment longevity: Prioritize a robust preventative maintenance schedule for the water cooling circuit, including regular checks for leaks, flow restrictions, and water quality.

- If your primary focus is product quality: Invest in precise control over the gas quenching system, ensuring you can program and verify specific cooling rates for different material requirements.

- If your primary focus is operational safety: Implement a strict, routine log for monitoring water temperatures and physically inspecting for hot spots, as this provides the first line of defense against unexpected failure.

Ultimately, the cooling system is the unsung hero of the furnace, providing the critical protection and precision needed for reliable, high-quality production.

Summary Table:

| System Component | Primary Function | Key Details |

|---|---|---|

| Water Cooling Circuit | Protects furnace structure from heat damage | Uses circulating water through channels in walls, doors, and components. |

| Gas Quenching System | Controls cooling rate of the workpiece | Uses high-speed inert gas (e.g., argon) to determine final material properties like hardness. |

| Key Considerations | Balancing competing factors | Includes cooling speed vs. material integrity and water quality vs. maintenance costs. |

Optimize your furnace's performance and protect your investment. The cooling system is critical for both equipment longevity and product quality. At KINTEK, we specialize in laboratory furnaces and the consumables that keep them running efficiently. Whether you need to upgrade your cooling system, require high-purity inert gases for quenching, or need expert advice on preventative maintenance, our team is here to help.

Contact KINTEK today to ensure your furnace operates reliably and delivers consistent, high-quality results.

Visual Guide

Related Products

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- 1400℃ Controlled Atmosphere Furnace with Nitrogen and Inert Atmosphere

- 1700℃ Controlled Atmosphere Furnace Nitrogen Inert Atmosphere Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- 1200℃ Controlled Atmosphere Furnace Nitrogen Inert Atmosphere Furnace

People Also Ask

- What does a high pressure switch do on a furnace? A Critical Safety Gatekeeper for Your Home

- What role do SiC sandpaper and alumina polishing suspension play in steel pretreatment? Achieve Optimal Coating Adhesion

- What are the technical advantages of using zirconia (ZrO2) grinding balls? Enhancing Silicon Composite Anode Performance

- Why are zirconia milling jars and balls required for Li2S composites? Ensure Purity in Solid Electrolyte Synthesis

- What is furnace lining? The Engineered System Protecting Your High-Temperature Processes

- Why is a laboratory oven required for the pretreatment of Meranti wood sawdust prior to pyrolysis experiments? Enhancing Bio-oil Quality

- Why are zirconia grinding jars and balls preferred for all-solid-state lithium-sulfur battery electrodes?

- What are the advantages of using Rotary Vane Vacuum Pumps? The Versatile Workhorse for Laboratory Efficiency