The fundamental difference between a muffle furnace and a tubular furnace is atmosphere control. A muffle furnace is designed for heating samples in ambient air, whereas a tubular furnace uses a sealed tube to allow for precise control over the gaseous environment. This core distinction dictates their respective designs, applications, and costs.

Choosing between them is a decision between sample capacity and process control. Muffle furnaces provide a large, simple chamber for general-purpose heating in air, while tubular furnaces offer a tightly controlled environment for specialized processes that require specific gases or a vacuum.

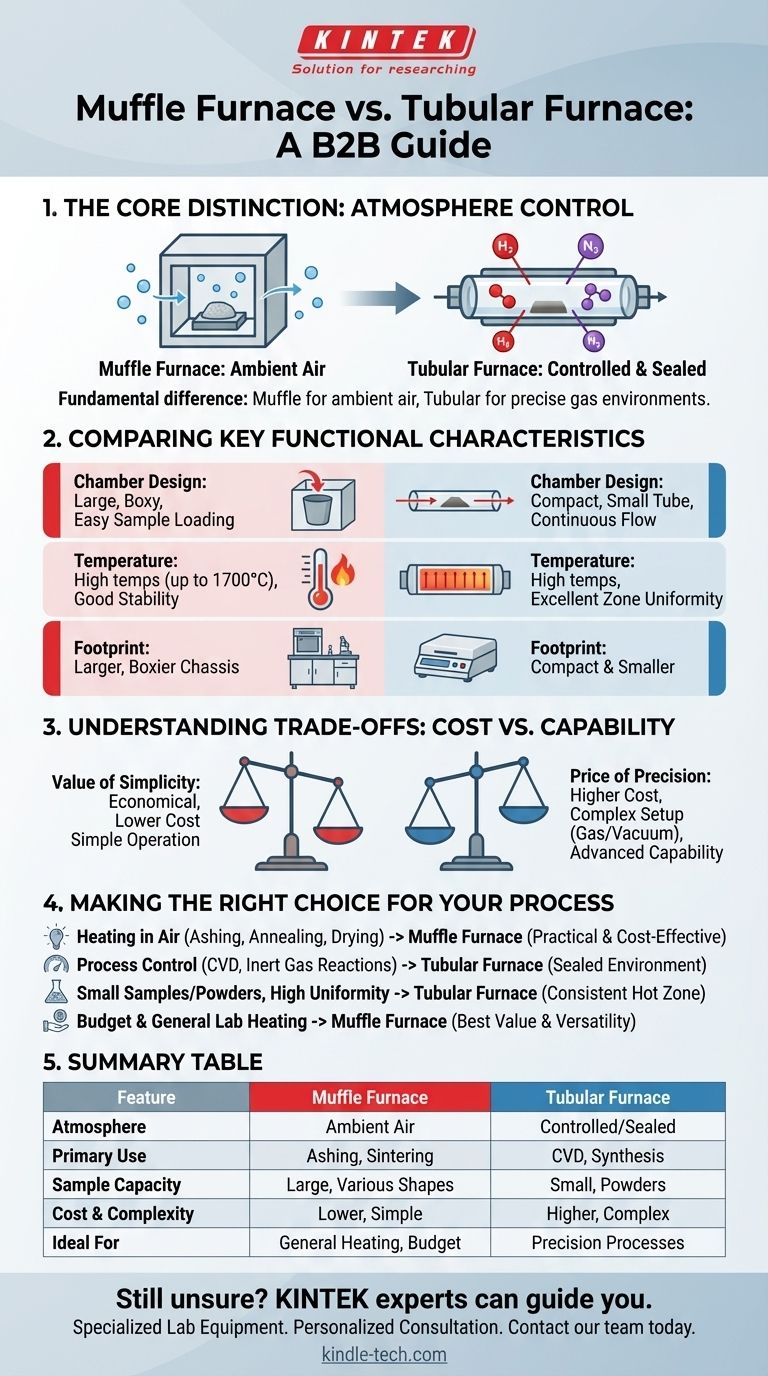

The Core Distinction: Atmosphere Control

The most critical factor separating these two furnace types is their ability to manage the environment around the sample. This capability, or lack thereof, defines their ideal use cases.

Muffle Furnace: Heating in Air

A muffle furnace is essentially a box-type chamber with heating elements surrounding a thermally insulated core. Its design is open to the ambient environment.

This makes it perfect for thermal processes that only require high heat in the presence of air, such as ashing, sintering, annealing, and gravimetric analysis. It is a workhorse for general-purpose lab heating.

Tubular Furnace: Precision Gas Environments

A tubular furnace heats a cylindrical tube, typically made of quartz, alumina, or mullite, which contains the sample. This tube can be sealed at both ends.

The sealed design is its key advantage. It allows you to purge the air and introduce specific gases, creating an inert (e.g., Argon, Nitrogen), reducing (e.g., Hydrogen), or otherwise controlled atmosphere. This is essential for sensitive applications like chemical vapor deposition (CVD), purification, or material synthesis where oxygen would interfere with the process.

Comparing Key Functional Characteristics

Beyond atmosphere control, their physical design leads to significant differences in sample handling, temperature profiles, and physical footprint.

Chamber Design and Sample Handling

A muffle furnace features a large, boxy chamber. This provides ample space and makes it extremely easy to load and unload samples of various shapes and sizes, often placed in ceramic crucibles or trays.

A tubular furnace has a much smaller, constrained heating zone within the narrow tube. This is ideal for smaller samples, powders, or for creating a continuous flow process where materials are passed through the hot zone.

Temperature Range and Uniformity

Both furnace types can achieve very high temperatures, often exceeding 1200°C. A muffle furnace's maximum temperature is determined by its heating elements, which may be electric heating wire (up to 1200°C), silicon-carbon rods (up to 1400°C), or silicon molybdenum rods (up to 1700°C).

While both provide good temperature stability, a tubular furnace often excels at creating a highly uniform temperature zone along a specific length of the tube, which can be critical for consistent sample processing.

Physical Footprint

Due to their designs, tubular furnaces are typically more compact and smaller than muffle furnaces, which require a larger, boxier chassis to house the insulated chamber.

Understanding the Trade-offs: Cost vs. Capability

Your choice will inevitably involve balancing the technical requirements of your process against budget and operational complexity.

The Price of Precision

A tubular furnace is significantly more expensive. This higher cost pays for the advanced capability of atmosphere control, including the sealed tube, gas-tight fittings, and often the associated vacuum pumps and gas flow controllers.

The Value of Simplicity

A muffle furnace is the more economical option. Its simpler design, focused solely on heating, makes it less expensive to purchase, operate, and maintain. For applications that do not require atmosphere control, it provides outstanding value.

Operational Complexity

Operating a muffle furnace is straightforward: place the sample, set the temperature, and start the program. A tubular furnace system is inherently more complex, requiring careful setup of gas lines, leak checks, and management of flow rates to ensure the desired atmosphere is achieved and maintained.

Making the Right Choice for Your Process

Your decision should be guided by the non-negotiable requirements of your thermal process.

- If your primary focus is heating samples in air (e.g., ashing, annealing, drying): A muffle furnace is the most practical and cost-effective choice due to its large chamber and operational simplicity.

- If your primary focus is process control with specific gas atmospheres (e.g., CVD, reactions under inert gas): A tubular furnace is the necessary tool, providing the sealed environment required for these applications.

- If your primary focus is processing small samples or powders with high-temperature uniformity: A tubular furnace often provides a more consistent and well-defined hot zone.

- If your primary focus is budget and general-purpose lab heating: A muffle furnace offers the best value and versatility for all standard air-atmosphere tasks.

Ultimately, your choice depends on a single question: does your process require control over the gaseous environment?

Summary Table:

| Feature | Muffle Furnace | Tubular Furnace |

|---|---|---|

| Atmosphere | Ambient Air | Controlled (Inert, Reducing, Vacuum) |

| Primary Use | Ashing, Sintering, Annealing in air | CVD, Synthesis, processes requiring specific gases |

| Sample Capacity | Large, boxy chamber for various samples | Small, constrained tube for powders/small samples |

| Cost & Complexity | Lower cost, simpler operation | Higher cost, more complex setup and operation |

| Ideal For | General-purpose heating, budget-conscious labs | Precision processes requiring atmosphere control |

Still unsure which furnace is right for your application? The experts at KINTEK are here to help. We specialize in lab equipment and consumables, serving all your laboratory needs. Whether you require the simplicity of a muffle furnace for ashing or the precision of a tubular furnace for CVD, we can guide you to the perfect solution for your process and budget. Contact our team today for a personalized consultation!

Visual Guide

Related Products

- 1700℃ Muffle Oven Furnace for Laboratory

- 1800℃ Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What is the purpose of a muffle furnace in a lab? Achieve Pure, High-Temperature Heat for Your Materials

- What is the use of muffle furnace in pharmaceutical industry? Ensure Drug Purity with Precise High-Temp Analysis

- What is the significance of a muffle furnace? Achieve Uncontaminated, High-Purity Heating

- What is the use of muffle furnace in food laboratory? Essential for Accurate Nutritional Analysis & Quality Control

- What are the safety precautions for heat experiment? Essential Steps to Prevent Lab Burns and Accidents