The primary significance of a muffle furnace lies in its unique ability to heat materials within a completely isolated chamber. This design shields the sample from the heating elements and any potential contaminants, such as combustion byproducts, ensuring that the thermal process itself is pure, precise, and highly repeatable.

A muffle furnace is not just a high-temperature oven; its defining value comes from the muffle—the protective barrier that guarantees the integrity of the material being processed. This principle of isolation is what makes it an indispensable tool for scientific analysis and advanced materials processing.

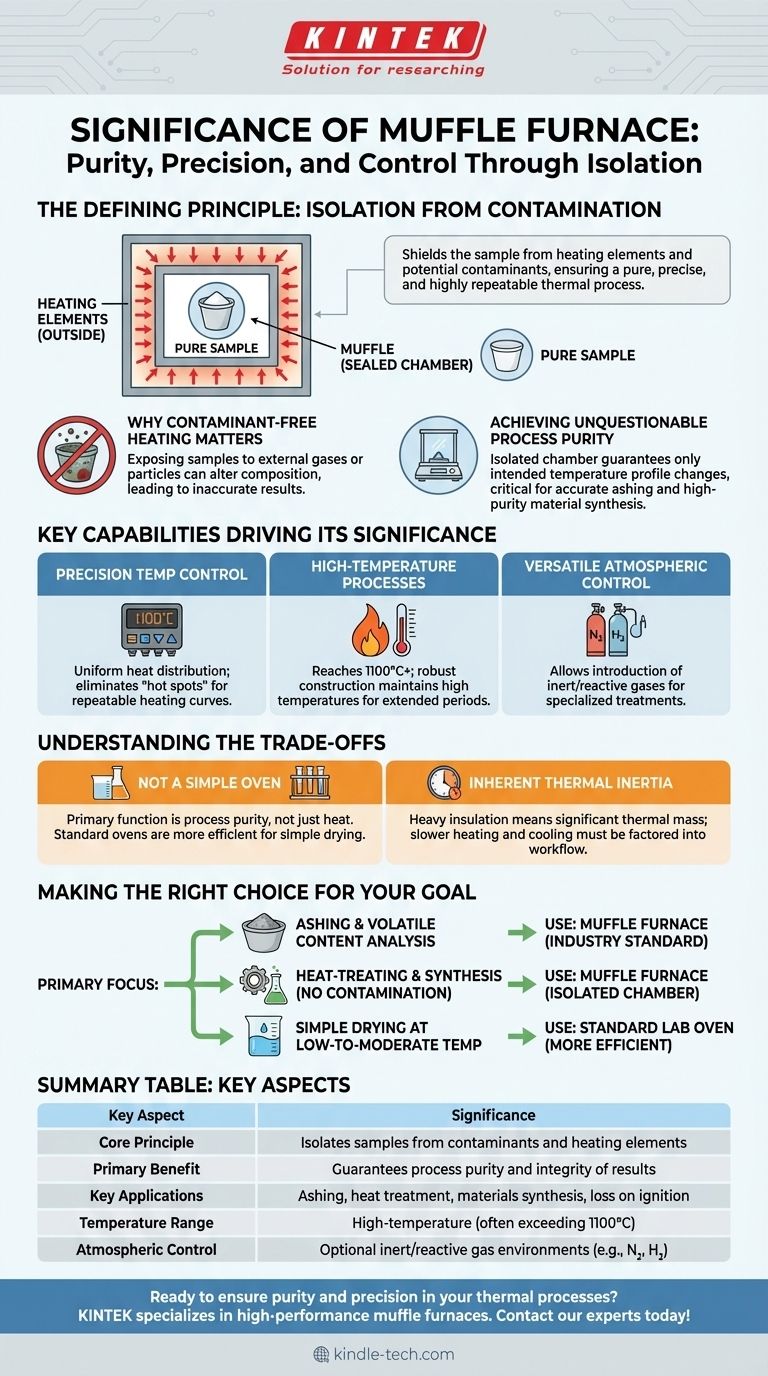

The Defining Principle: Isolation from Contamination

The true value of this equipment is understood by looking past the high heat and focusing on the chamber design itself. Its significance is rooted in preventing external influence on the sample.

What is the "Muffle"?

A muffle is an enclosed, sealed chamber placed inside the furnace. The material you wish to heat is placed inside this muffle.

The heating elements of the furnace heat the outside of the muffle. The heat then radiates through the muffle's walls to uniformly heat the contents within.

This design creates a crucial barrier. In older fuel-fired furnaces, it kept damaging combustion gases away from the sample. In modern electric furnaces, it prevents any direct interaction with the heating elements, which can degrade and release trace contaminants over time.

Why Contaminant-Free Heating Matters

For many scientific and industrial processes, purity is non-negotiable.

Exposing a sample to external gases or microscopic particles can fundamentally alter its chemical composition, leading to inaccurate analytical results or flawed material properties.

For example, when determining the ash content of a sample, any soot from combustion would invalidate the measurement. The muffle eliminates this possibility.

Achieving Unquestionable Process Purity

The isolated chamber ensures that the only changes to the sample are a direct result of the intended temperature profile.

This allows for incredibly accurate results in processes like ashing, where all organic material is burned away to precisely measure the remaining inorganic content. It also enables the creation of high-purity materials in research and manufacturing.

Key Capabilities Driving Its Significance

Beyond isolation, the muffle furnace's design provides several other critical benefits that make it a cornerstone of modern laboratories and industrial facilities.

Precision Temperature Control and Uniformity

The insulated, enclosed muffle promotes exceptionally uniform heat distribution. There are no "hot spots" from direct exposure to a flame or heating element.

This, combined with modern digital controllers, allows for extremely precise temperature control, which is vital for experiments and processes that require repeatable and specific heating curves.

Handling Demanding High-Temperature Processes

Muffle furnaces are specifically engineered for high-temperature applications, often reaching 1100°C or higher.

Their robust construction and advanced insulation are designed to safely and efficiently maintain these temperatures for extended periods, far exceeding the capabilities of a standard laboratory oven.

Versatile Atmospheric Control

Many advanced muffle furnaces allow for the introduction of specific gases into the chamber, such as nitrogen or hydrogen.

This enables operators to create an inert or reactive atmosphere, which is essential for heat-treating metals without oxidation or for conducting specialized chemical reactions.

Understanding the Trade-offs

While powerful, a muffle furnace is a specialized tool, and its design comes with certain practical considerations.

Not a Simple High-Temperature Oven

The primary function is process purity, not just heat. For simple applications like drying glassware or warming non-sensitive materials, a standard convection oven is often a more practical and energy-efficient choice.

Inherent Thermal Inertia

The heavy insulation and robust construction required to maintain high temperatures mean that muffle furnaces have significant thermal mass.

Consequently, they can take a considerable amount of time to heat up to the target temperature and even longer to cool down safely. This must be factored into any workflow.

Making the Right Choice for Your Goal

Ultimately, the decision to use a muffle furnace should be based on the specific requirements of your process.

- If your primary focus is determining the inorganic ash or volatile content of a sample: A muffle furnace is the essential, industry-standard tool for this analysis.

- If your primary focus is heat-treating metals or synthesizing materials without contamination: The isolated chamber and optional atmospheric control make it the ideal choice.

- If your primary focus is simply drying samples at low-to-moderate temperatures: A standard laboratory oven is a more efficient and appropriate solution.

By understanding its core principle of isolation, you can leverage the muffle furnace for applications that demand the highest degree of purity, precision, and control.

Summary Table:

| Key Aspect | Significance |

|---|---|

| Core Principle | Isolates samples from contaminants and heating elements |

| Primary Benefit | Guarantees process purity and integrity of results |

| Key Applications | Ashing, heat treatment, materials synthesis, loss on ignition |

| Temperature Range | High-temperature (often exceeding 1100°C) |

| Atmospheric Control | Optional inert/reactive gas environments (e.g., N₂, H₂) |

Ready to ensure purity and precision in your thermal processes? KINTEK specializes in high-performance muffle furnaces designed for laboratories that demand uncontaminated heating and accurate, repeatable results. Whether your work involves ashing, heat treatment, or advanced materials synthesis, our equipment delivers the reliability you need. Contact our experts today to find the perfect solution for your application!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1700℃ Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- 1800℃ Muffle Oven Furnace for Laboratory

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- What is a muffle furnace used for in microbiology? Essential for Depyrogenation and Ashing

- What are the uses of muffle furnace in pharmaceutical industry? Essential for Drug Purity & Safety

- Why is ceramic used in making furnace? Achieve Superior Heat Resistance and Efficiency

- What is the muffle furnace method? A Guide to Clean, High-Temperature Processing

- How is the sintering temperature related to the melting temperature? A Guide to Solid-State Bonding