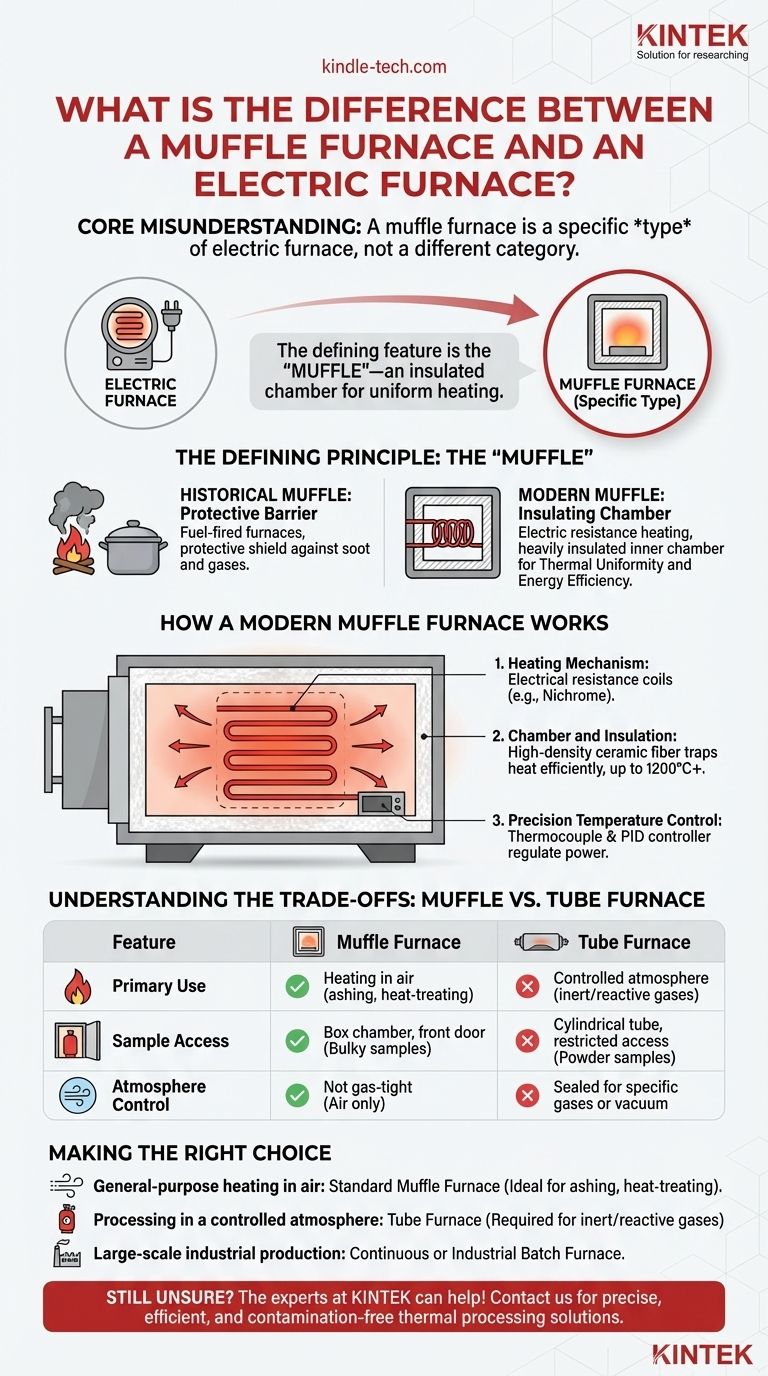

At its core, the question contains a common misunderstanding. A muffle furnace is not a different category from an electric furnace; it is a specific type of electric furnace. The defining feature is the "muffle"—an insulated chamber that isolates the material being heated. While historically this protected samples from the byproducts of fuel combustion, in modern electric models, it refers to the design that ensures uniform heating and thermal efficiency.

The key distinction is not about the power source but about design and purpose. A "muffle furnace" is an electric furnace built with a highly insulated chamber designed to isolate the sample, providing a uniform and controlled high-temperature environment free from contamination.

The Defining Principle: The "Muffle"

The confusion between these terms stems from the evolution of the word "muffle." Understanding its original and modern meanings clarifies the entire concept.

The Historical Muffle: A Protective Barrier

Originally, furnaces were fuel-fired, burning coal, wood, or gas. This created a harsh environment filled with soot and reactive gases from combustion.

A muffle was a separate, sealed container (often made of ceramic) placed inside the main furnace. It acted as a physical shield, protecting the sample from direct contact with the flames and their chemical byproducts.

The Modern Muffle: An Insulating Chamber

Modern laboratory furnaces are overwhelmingly electric. They use resistance heating elements that generate heat without any combustion, eliminating the original need for a protective barrier against byproducts.

In this context, the term "muffle" has evolved. It now refers to the furnace's heavily insulated inner chamber itself, which isolates the heating area from the outside environment. This design ensures two critical outcomes:

- Thermal Uniformity: The heat radiates evenly from the chamber walls onto the sample.

- Energy Efficiency: The insulation prevents heat from escaping, allowing for rapid heating and stable high temperatures.

How a Modern Muffle Furnace Works

A modern muffle furnace is an elegantly simple system designed for precise, high-temperature work. Its operation is based on a few key components.

The Heating Mechanism

The furnace works on the principle of electrical resistance. High-resistance wire coils, often made of materials like Nichrome, are wound around the chamber. When a powerful electric current is passed through them, they glow red-hot, converting electrical energy into heat.

The Chamber and Insulation

This heat is radiated inward, into the muffle chamber. The chamber is constructed from high-performance refractory ceramic materials that can withstand extreme temperatures (often up to 1200°C or higher).

This entire heating assembly is encased in a thick layer of high-density ceramic fiber insulation. This insulation is what acts as the muffle, trapping the heat with extreme efficiency.

Precision Temperature Control

A thermocouple inside the chamber constantly measures the temperature. This data is fed to a PID (Proportional-Integral-Derivative) controller, a small computer that precisely regulates the power sent to the heating coils to maintain the exact target temperature set by the user.

Understanding the Trade-offs: Muffle vs. Other Furnace Types

While a muffle furnace is a versatile tool, its design creates specific advantages and limitations compared to other specialized furnaces, such as a tube furnace.

Atmosphere Control

This is the most critical trade-off. A standard muffle furnace is designed for heating samples in air. It is not sealed to be gas-tight.

If your process requires heating under a specific gas (like nitrogen or argon) or in a vacuum, you need a tube furnace. A tube furnace is specifically designed to control the atmosphere around the sample.

Sample Volume and Access

Muffle furnaces typically have a box-shaped chamber with a front-opening door. This provides a large heating zone and makes it easy to place and retrieve bulky or awkwardly shaped samples.

A tube furnace has a much more restrictive, cylindrical chamber, which is better suited for smaller or powder-based samples.

Cost and Temperature Range

For most general-purpose applications below 1200°C, a muffle furnace offers the best balance of performance and cost.

While some specialized tube furnaces can achieve higher temperatures, they are generally more expensive and complex due to the need for gas-tight seals and specialized tube materials.

Making the Right Choice for Your Application

Selecting the correct furnace depends entirely on the requirements of your process.

- If your primary focus is general-purpose heating in air: A standard muffle furnace is the ideal, cost-effective tool for applications like ashing, heat-treating metals, materials research, and ceramic firing.

- If your primary focus is processing samples in a controlled atmosphere: You must use a tube furnace, as a muffle furnace cannot provide the gas-tight environment required for working with inert or reactive gases.

- If your primary focus is large-scale industrial production: You are likely looking for a continuous or industrial batch furnace, which may incorporate muffle principles but is engineered for much larger capacities and continuous operation.

Ultimately, understanding that the "muffle" is a design principle for isolation and insulation empowers you to select the precise tool for your specific thermal processing task.

Summary Table:

| Feature | Muffle Furnace | Tube Furnace |

|---|---|---|

| Primary Use | Heating in air (ashing, heat-treating) | Controlled atmosphere (inert/reactive gases) |

| Sample Access | Box chamber, front door | Cylindrical tube, restricted access |

| Atmosphere Control | Not gas-tight (air only) | Sealed for specific gases or vacuum |

| Ideal For | General-purpose, bulky samples | Specialized processes, powder samples |

Still unsure which furnace is right for your application? The experts at KINTEK can help! We specialize in providing the perfect lab equipment, including muffle furnaces and tube furnaces, to meet your specific thermal processing needs. Contact us today for a personalized consultation and let us help you achieve precise, efficient, and contamination-free results in your laboratory.

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1700℃ Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- 1800℃ Muffle Oven Furnace for Laboratory

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- What role does a high-temperature muffle furnace play in determining the VS content? Precision in Compost Analysis

- What is the difference between muffle furnace and hot air oven? Choose the Right Heating Tool for Your Lab

- What is the main function of a muffle furnace? Achieve Pure, High-Temperature Processing

- What are the three types of quenching? Mastering the Stages of Heat Transfer for Optimal Hardness

- What is the role of high-temperature muffle or tube furnaces in LLZTO synthesis? Master Cubic Phase Ceramic Production

- What role does a box resistance furnace play in the pretreatment of coal gangue? Enhance ZSM-5 Zeolite Synthesis Results

- How does a high-temperature box sintering furnace contribute to the densification of oxygen transport membranes?

- What is the function of a box resistance furnace in szaibelyite pretreatment? Optimize High-Temperature Calcination