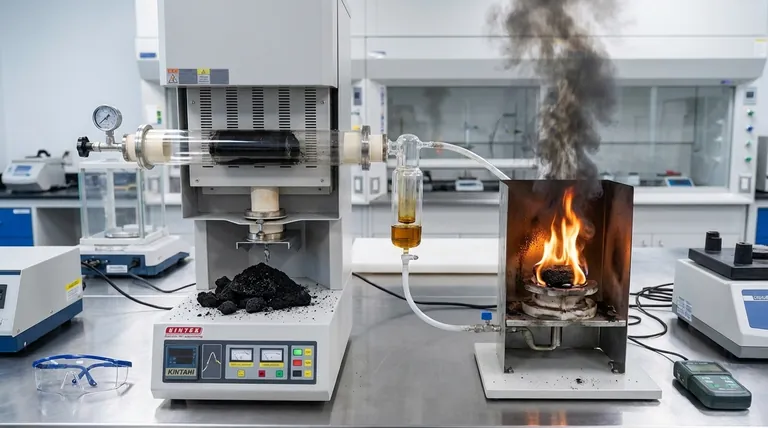

The fundamental difference between pyrolysis and incomplete combustion lies entirely in the presence and role of oxygen. Pyrolysis is the thermal decomposition of a material in the complete absence of oxygen, breaking it down with heat alone. Incomplete combustion is a chemical reaction—a type of burning—that occurs when there is an insufficient supply of oxygen.

While both processes involve high temperatures and carbon-based materials, they are fundamentally opposed in their chemistry and goals. Pyrolysis uses an oxygen-free environment to create valuable, energy-rich products, whereas incomplete combustion is an inefficient, oxygen-starved reaction that produces hazardous waste.

The Defining Factor: The Role of Oxygen

The presence or absence of oxygen dictates whether a material is chemically transformed or simply burned inefficiently. This single variable changes the energy balance, the reaction type, and all resulting products.

Pyrolysis: Thermal Decomposition Without Oxygen

Pyrolysis is a controlled process that uses external heat to break down complex organic materials. Because there is no oxygen, the material cannot actually burn or oxidize.

It is primarily an endothermic process, meaning it requires a constant input of energy to sustain the reaction.

The goal is not to release energy as heat, but to preserve the chemical energy from the original material in the new, simpler products it creates.

Incomplete Combustion: An Oxygen-Starved Reaction

Incomplete combustion is a true burning process where a material reacts with oxygen. However, the reaction is starved of a sufficient amount of oxygen.

This is an exothermic reaction, meaning it releases energy in the form of heat, but it does so very inefficiently compared to complete combustion.

Instead of fully oxidizing the fuel to carbon dioxide and water, the lack of oxygen leaves the reaction unfinished, creating undesirable byproducts.

Contrasting the Outputs and Their Value

The outputs of each process clearly reflect their underlying chemistry. One creates a suite of valuable resources, while the other produces waste and pollutants.

Products of Pyrolysis: Energy-Rich and Stable

By deconstructing material without burning it, pyrolysis creates a set of high-value, energy-dense products that can be stored, transported, and used later:

- Bio-char: A stable, carbon-rich solid similar to charcoal.

- Bio-oil: A dense, liquid mixture of organic compounds that can be refined into fuel.

- Syngas: A mixture of flammable gases, primarily hydrogen and carbon monoxide.

Products of Incomplete Combustion: Wasteful and Hazardous

Because the fuel is not fully consumed, incomplete combustion generates low-value and often dangerous byproducts:

- Soot (Black Carbon): Tiny, unburnt solid particles of carbon that we see as smoke.

- Carbon Monoxide (CO): A toxic, colorless, and odorless gas.

- Unburnt Hydrocarbons: Volatile organic compounds that contribute to smog.

Understanding the Applications and Goals

Pyrolysis is an intentional industrial tool, while incomplete combustion is almost always a sign of a system failure.

The Goal of Pyrolysis: Resource Creation

Engineers use pyrolysis intentionally to achieve a specific outcome. It is a cornerstone of waste-to-energy technologies and the advanced biofuels industry.

The objective is to convert low-value feedstock, like agricultural waste or plastics, into high-value chemical products and fuels.

The Problem of Incomplete Combustion: Process Failure

Incomplete combustion is rarely, if ever, a desired outcome. It signifies a problem in a system designed for efficient burning, such as a furnace, boiler, or internal combustion engine.

The appearance of soot or the detection of carbon monoxide indicates that the system is not receiving enough air, wasting fuel and creating a dangerous environment. The goal is always to fix the issue to achieve complete combustion.

How to Apply This to Your Goal

Your understanding of these processes depends entirely on what you are trying to achieve.

- If your primary focus is creating valuable, storable energy products from raw materials: Pyrolysis is the correct industrial process, as it chemically transforms feedstock into stable fuels like bio-char and bio-oil.

- If your primary focus is maximizing heat release from a fuel source: Your goal is complete combustion, and you must ensure a sufficient oxygen supply to prevent the inefficiency and hazardous byproducts of incomplete combustion.

- If you are analyzing an inefficient burning process that produces soot and smoke: You are observing incomplete combustion, which indicates a problem with the air-to-fuel ratio that needs immediate correction.

Understanding the critical role of oxygen is the key to distinguishing these processes and harnessing thermal energy effectively.

Summary Table:

| Feature | Pyrolysis | Incomplete Combustion |

|---|---|---|

| Oxygen Presence | Complete absence | Insufficient supply |

| Reaction Type | Endothermic (requires heat) | Exothermic (releases heat) |

| Primary Goal | Create valuable products (bio-oil, syngas) | An inefficient, problematic form of burning |

| Typical Products | Bio-char, bio-oil, syngas | Soot, carbon monoxide, unburnt hydrocarbons |

| Industrial Status | Intentional, controlled process | Sign of system failure or inefficiency |

Need precise thermal processing for your lab or pilot plant?

Understanding the difference between pyrolysis and combustion is critical for safety, efficiency, and achieving your research and development goals. KINTEK specializes in high-quality lab equipment, including pyrolysis reactors and furnaces designed for controlled, oxygen-free environments.

Let our experts help you select the right equipment to transform your materials effectively and safely.

Contact KINTEK today to discuss your specific laboratory needs and how our solutions can drive your projects forward.

Visual Guide

Related Products

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

- 1400℃ Laboratory Quartz Tube Furnace with Alumina Tube Tubular Furnace

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- 1700℃ Laboratory Quartz Tube Furnace with Alumina Tube Tubular Furnace

- 1800℃ Muffle Oven Furnace for Laboratory

People Also Ask

- What is the difference between upflow and horizontal furnace? Find the Perfect Fit for Your Home's Layout

- What is the standard thickness of plating? Optimize Durability, Corrosion & Cost

- What is quartz tube heating? Achieve Instant, Targeted Heat with Infrared Radiation

- What is a vertical tube furnace? Leverage Gravity for Superior Uniformity and Process Control

- How do you clean a tubular furnace tube? A Step-by-Step Guide to Safe and Effective Maintenance