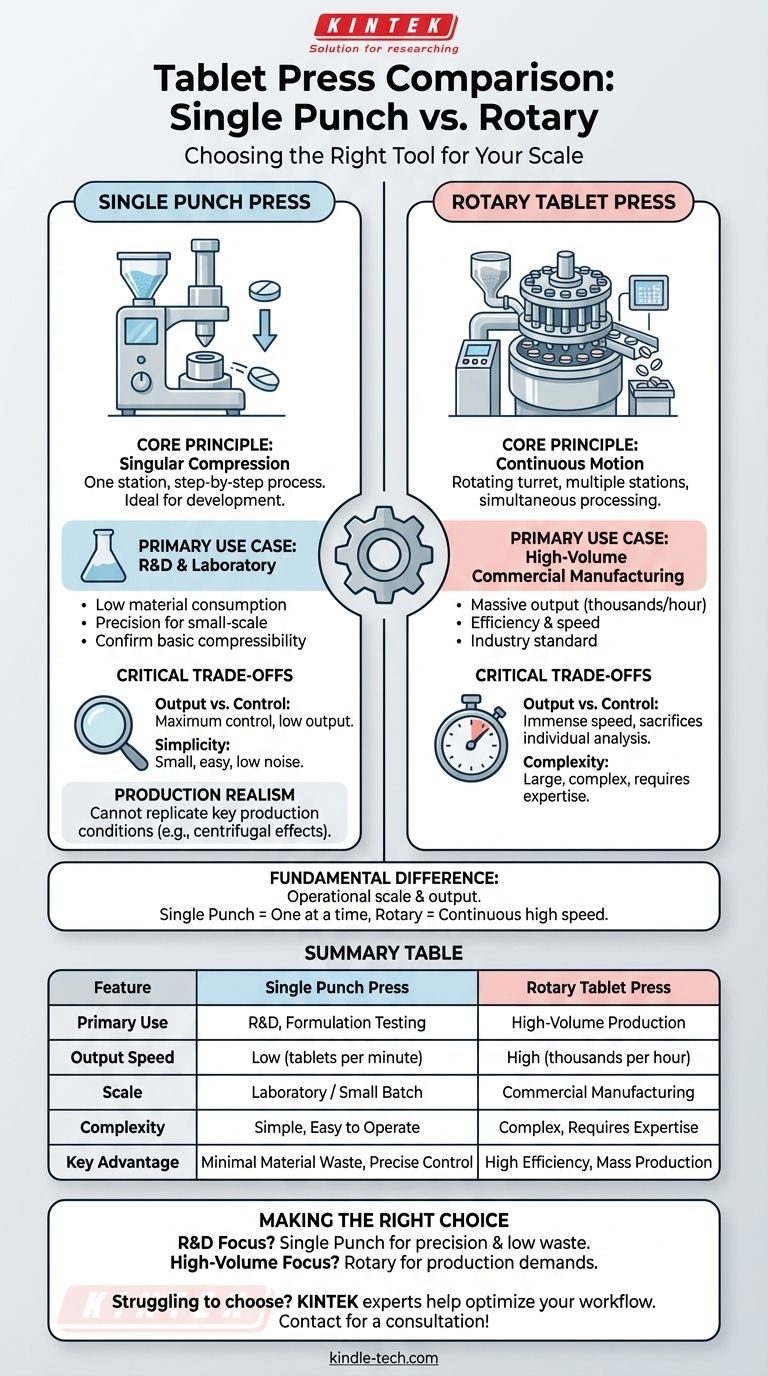

The fundamental difference between a single punch and a rotary tablet press lies in their operational scale and output. A single punch press utilizes one station with a single die and punch set to compress tablets one at a time, making it ideal for development. A rotary press, by contrast, uses multiple stations mounted on a rotating turret to produce tablets continuously at high speed, designed for large-scale manufacturing.

The choice between a single punch and a rotary press is not a matter of which is superior, but which tool is appropriate for the task at hand. Your decision hinges entirely on whether your objective is formulation and testing or high-volume production.

Deconstructing the Single Punch Press

A single punch press, also known as an eccentric press, is the simplest form of tablet compression machine. Its design is straightforward and focused on precision for small-scale operations.

Core Principle: Singular Compression

The machine operates with a single set of tooling. Powder flows from a hopper into a die cavity, a top punch descends to compress the material, and then the finished tablet is ejected. This cycle repeats for each tablet, making it a deliberate, step-by-step process.

Key Components

The primary components are few and easy to understand. A hopper holds the powder, which is fed into a die cavity. Upper and lower punches compress the powder, and an ejection cam pushes the final tablet out of the die.

Primary Use Case: Research & Development

This type of press excels in laboratory and R&D settings. Its low material consumption is perfect for working with expensive or limited active pharmaceutical ingredients (APIs). It is the ideal tool for confirming the basic compressibility of a new formulation.

Understanding the Rotary Tablet Press

The rotary press, or multi-station press, is the workhorse of industrial tablet manufacturing. It is engineered for efficiency, speed, and massive output.

Core Principle: Continuous Motion

Instead of a single station, a rotary press features a large, rotating turret holding numerous sets of dies and punches. As the turret spins, each station moves sequentially through the filling, compression, and ejection stages simultaneously.

The Output Multiplier Effect

This continuous, parallel processing allows for the production of thousands, and even hundreds of thousands, of tablets per hour. This makes it the only viable option for commercial-scale manufacturing.

Types of Rotary Presses

These machines can be further categorized, with common types being single-sided and double-sided rotary presses. Double-sided models essentially double the output by having two sets of filling and compression cams.

The Critical Trade-offs

Choosing the wrong machine for your stage of development can be a costly mistake. Understanding the limitations of each design is crucial.

Output vs. Control

A single punch press offers maximum control over the compression event for a single tablet but has an extremely low output. A rotary press sacrifices individual tablet analysis for immense speed and volume.

Simplicity vs. Complexity

The single punch press is small, easy to operate, and has low noise levels. Rotary presses are large, complex industrial machines that require significant setup, maintenance, and operator expertise.

A Note on Production Realism

While excellent for initial tests, a single punch press cannot replicate key production conditions. Forces like centrifugal effects on powder feeding and the behavior of mechanical feeders are only present in a rotary press, which is a critical consideration when scaling up a formulation.

Making the Right Choice for Your Goal

Your specific objective dictates the correct tool. The decision is a direct reflection of your position in the product lifecycle, from initial concept to the factory floor.

- If your primary focus is R&D or formulation testing: The single punch press is the clear choice for its precision, ease of use, and minimal material waste.

- If your primary focus is high-volume commercial manufacturing: The rotary tablet press is the industry standard and the only machine capable of meeting production demands.

Ultimately, these two machines serve distinct but complementary roles in the journey of bringing a product to market.

Summary Table:

| Feature | Single Punch Press | Rotary Tablet Press |

|---|---|---|

| Primary Use | R&D, Formulation Testing | High-Volume Production |

| Output Speed | Low (tablets per minute) | High (thousands per hour) |

| Scale | Laboratory / Small Batch | Commercial Manufacturing |

| Complexity | Simple, Easy to Operate | Complex, Requires Expertise |

| Key Advantage | Minimal Material Waste, Precise Control | High Efficiency, Mass Production |

Struggling to choose the right tablet press for your lab or production line? KINTEK specializes in lab equipment and consumables, serving all your laboratory needs. Whether you're in R&D requiring the precision of a single punch press or scaling up to high-volume manufacturing with a rotary press, our experts can help you select the perfect machine to optimize your workflow, reduce costs, and ensure quality. Contact KINTEL today for a personalized consultation!

Visual Guide

Related Products

- Single Punch Electric Tablet Press Machine TDP Tablet Punching Machine

- Single Punch Tablet Press Machine and Mass Production Rotary Tablet Punching Machine for TDP

- Single Punch Electric Tablet Press Machine Laboratory Powder Tablet Punching TDP Tablet Press

- Lab Scale Rotary Single Punch Tablet Press Machine TDP Tablet Punching Machine

- Single Punch Manual Tablet Press Machine TDP Tablet Punching Machine

People Also Ask

- What do you press pills with? The Essential Guide to Tablet Press Machines

- What are the different parts of a single punch tablet machine? The Core Components Explained

- What is die compression ratio? Master Your Pelleting Process for Optimal Quality & Efficiency

- What are the advantages of tablet press machine? Achieve High-Speed, Consistent Production

- What are the different pill presses? Choose the Right Machine for Your Lab or Production Scale