The primary advantages of a tablet press machine are its ability to deliver high-volume production, exceptional consistency across tablets, and precise control over the final product's physical characteristics. This technology transforms loose powder into uniform, solid doses with remarkable efficiency and repeatability, which is fundamental to modern manufacturing.

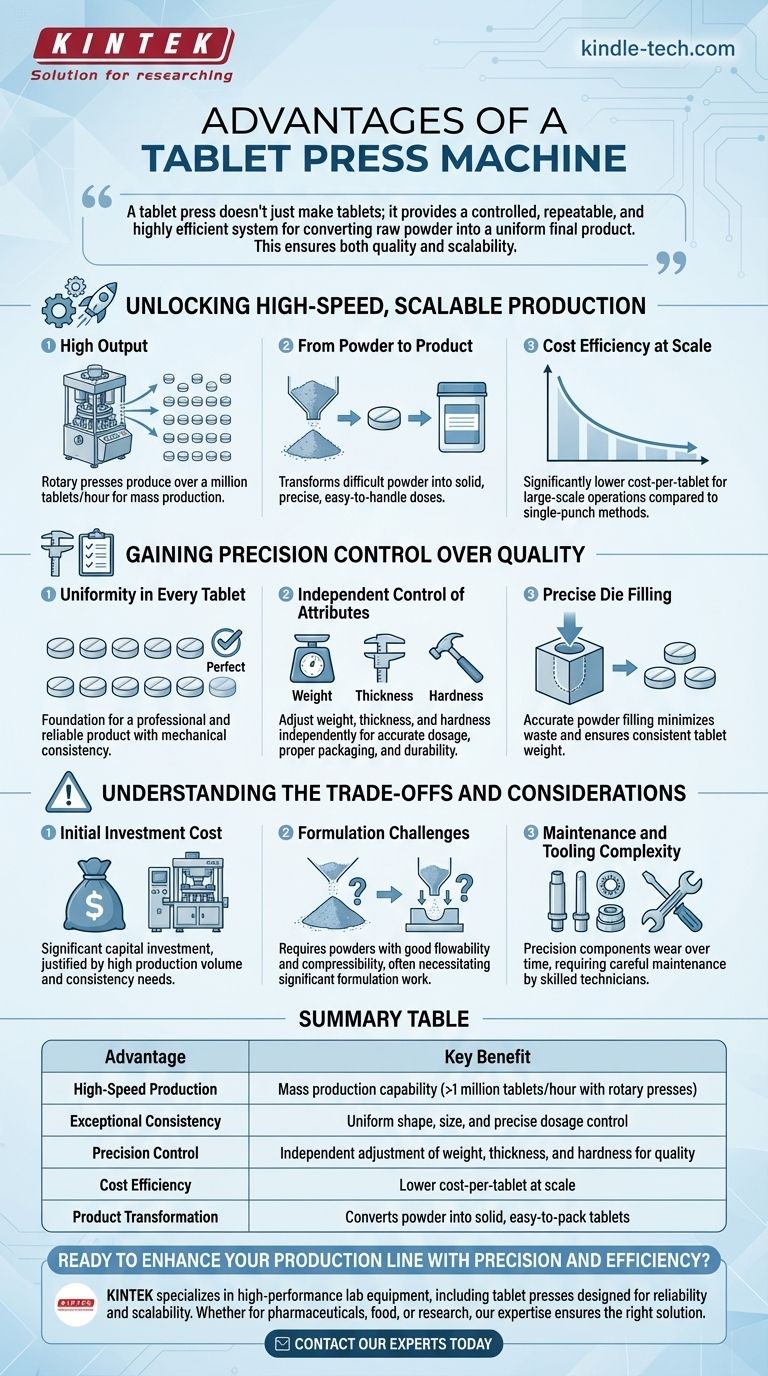

A tablet press doesn't just make tablets; it provides a controlled, repeatable, and highly efficient system for converting raw powder into a uniform final product. This ensures both quality and scalability in industries from pharmaceuticals to food production.

Unlocking High-Speed, Scalable Production

The core function of a tablet press is to compress powder into a tablet, but its true value lies in the efficiency and scale it brings to this process.

The Principle of High Output

Modern rotary tablet presses are engineered for mass production. By using multiple "stations" of punches and dies on a rotating turret, these machines can produce over a million tablets per hour, a rate unattainable with manual or less advanced methods.

From Powder to Product

A key advantage is the physical transformation of the material. A press turns a difficult-to-handle, dusty powder into a solid, compact tablet that is easy to package, transport, and consume, while ensuring a precise dose.

Cost Efficiency at Scale

For large-scale operations, a rotary tablet press is significantly more cost-efficient than single-punch presses or other methods. The high output rate dramatically lowers the cost-per-tablet, making it the industry standard for commercial manufacturing.

Gaining Precision Control Over Quality

Beyond speed, a tablet press offers a level of control that is critical for ensuring product quality, safety, and consistency.

Uniformity in Every Tablet

The most basic advantage is producing tablets of uniform shape and size. This mechanical consistency is the foundation for a professional and reliable product.

Independent Control of Key Attributes

Advanced presses allow operators to independently control critical tablet parameters like weight, thickness, and hardness. This control is vital for ensuring accurate dosage (weight), proper packaging (thickness), and durability during shipping (hardness).

Precise Die Filling

Efficient press operation includes precise control over the filling of the die cavity. This ensures that the correct amount of powder is used for each tablet, minimizing material waste and guaranteeing consistent tablet weight.

Understanding the Trade-offs and Considerations

While powerful, a tablet press is a specialized piece of machinery with its own set of challenges that require careful management.

Initial Investment Cost

High-speed, high-precision tablet presses represent a significant capital investment. The cost must be justified by the required production volume and the value of product consistency.

Formulation Challenges

A tablet press works best with powders that have specific characteristics, such as good flowability and compressibility. A powder that does not flow well will not fill the dies uniformly, and one that does not compress well will not form a strong tablet. Significant formulation work is often required to prepare a powder for tableting.

Maintenance and Tooling Complexity

The punches and dies, known as tooling, are precision components that wear over time and require careful maintenance, cleaning, and storage. The machine itself is complex and requires skilled technicians for setup, operation, and repair.

Making the Right Choice for Your Goal

Selecting the right equipment depends entirely on your specific production objectives.

- If your primary focus is mass production and efficiency: A rotary tablet press is the definitive choice due to its high output and lower cost-per-unit at scale.

- If your primary focus is research, development, or small batches: A less complex single punch press is often a more practical and cost-effective starting point.

- If your primary focus is quality and process control: Prioritize machines that offer independent control over tablet parameters and modern network capabilities for remote monitoring and data collection.

Ultimately, selecting the appropriate tablet press is a foundational step in building a reliable and scalable production line.

Summary Table:

| Advantage | Key Benefit |

|---|---|

| High-Speed Production | Mass production capability, over 1 million tablets/hour with rotary presses. |

| Exceptional Consistency | Uniform tablet shape, size, and precise dosage control. |

| Precision Control | Independent adjustment of weight, thickness, and hardness for quality assurance. |

| Cost Efficiency | Lower cost-per-tablet at scale compared to manual or single-punch methods. |

| Product Transformation | Converts difficult-to-handle powder into solid, easy-to-pack tablets. |

Ready to enhance your production line with precision and efficiency? KINTEK specializes in high-performance lab equipment, including tablet presses designed for reliability and scalability. Whether you're in pharmaceuticals, food production, or research, our expertise ensures you get the right solution for high-volume output and consistent quality. Contact our experts today to discuss your specific needs and discover how KINTEK can power your manufacturing success.

Visual Guide

Related Products

- Single Punch Electric Tablet Press Machine TDP Tablet Punching Machine

- Single Punch Tablet Press Machine and Mass Production Rotary Tablet Punching Machine for TDP

- Single Punch Electric Tablet Press Machine Laboratory Powder Tablet Punching TDP Tablet Press

- Single Punch Manual Tablet Press Machine TDP Tablet Punching Machine

- Lab Scale Rotary Single Punch Tablet Press Machine TDP Tablet Punching Machine

People Also Ask

- What is the principle of a single punch tablet press machine? A Guide to Precision Lab-Scale Production

- What is a biomass pellet machine? Transform Waste into Fuel, Feed, and Bedding

- What is a tablet punching machine called? Choosing the Right Press for Your Production Scale

- What is the process of making biomass pellets? A Step-by-Step Guide to Producing Clean Energy

- What components of a tablet press define the size and shape of the tablets? Mastering Die and Punch Tooling

- What is a tablet punch? The Precision Tool Shaping Your Tablet Manufacturing

- What are the different pill presses? Choose the Right Machine for Your Lab or Production Scale

- What is the function of rotary tablet press? High-Speed, High-Volume Tablet Production