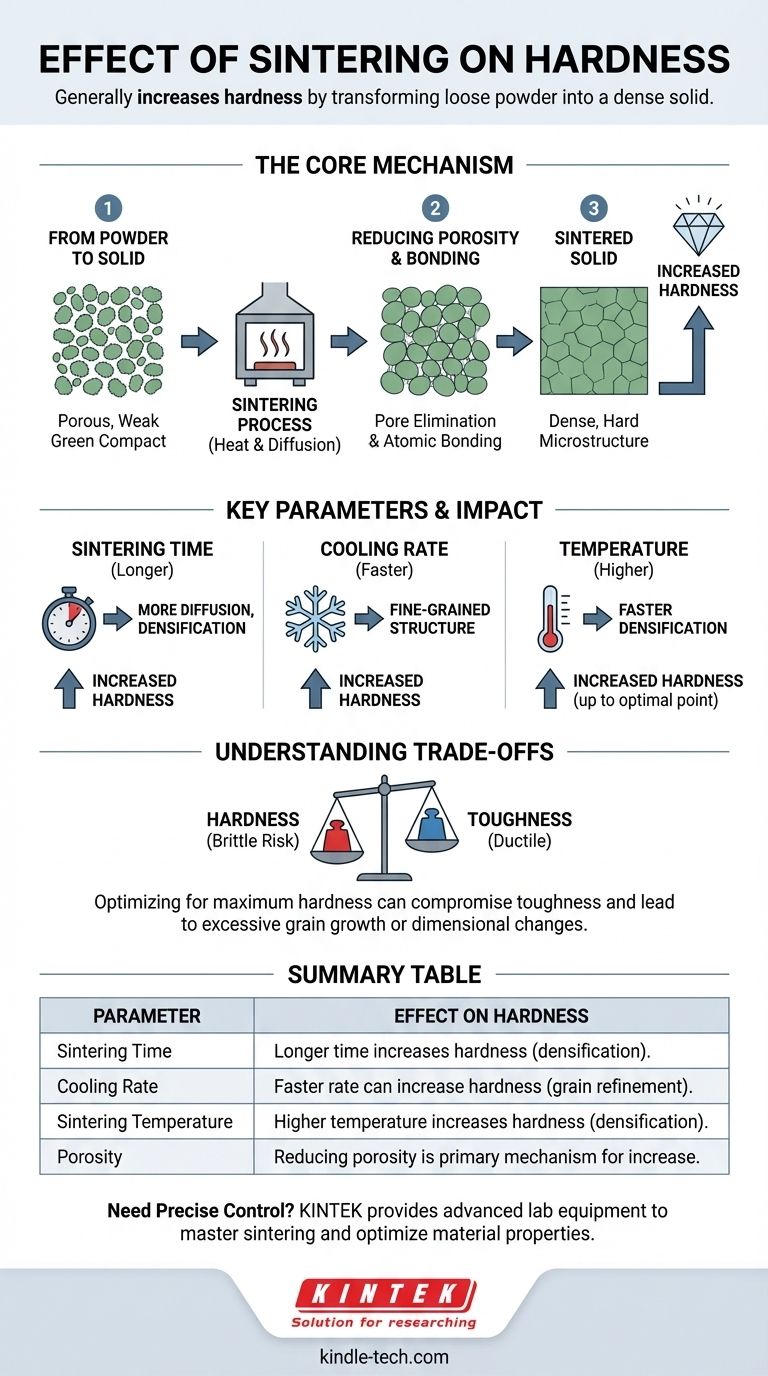

In short, sintering generally increases the hardness of a material. The process transforms a collection of loose particles into a dense, solid mass, and key parameters like sintering time and cooling rate can be adjusted to maximize this effect. A longer sintering duration and a faster cooling rate typically result in a harder final product.

The fundamental goal of sintering is to reduce porosity by fusing particles together. This creates a denser, more consolidated microstructure, and the resulting increase in hardness is a direct consequence of this improved internal structure.

The Core Mechanism: How Sintering Builds Hardness

Sintering is a thermal treatment process that converts a powder compact into a dense, strong component. This transformation is the root cause of the change in hardness.

From Powder to Solid

The starting material is often a "green compact"—a collection of particles pressed into a shape. This compact is porous and mechanically weak. Sintering applies heat below the material's melting point, providing the energy for atoms to bond across particle boundaries.

Reducing Porosity

The empty spaces, or pores, between the particles are the primary source of weakness in an unsintered part. During sintering, material diffuses to fill these voids, causing the part to shrink and densify. Eliminating this porosity is the single most important factor in increasing hardness.

Promoting Atomic Bonding

As pores are eliminated, strong metallurgical bonds form between the individual grains of the material. This creates a continuous, solid lattice that is far more resistant to deformation and indentation, which is the very definition of hardness.

Key Parameters and Their Impact

You can control the outcome of the sintering process by manipulating several key variables. Each has a direct and predictable effect on the final hardness.

The Role of Sintering Time

As noted in studies, increasing the duration of the sintering process allows more time for atomic diffusion to occur. This leads to more complete pore elimination and stronger bonds between grains, resulting in a denser and harder material.

The Influence of Cooling Rate

A faster cooling rate after sintering can "lock in" a desirable, fine-grained microstructure. For many materials, this fine-grained structure is harder and stronger than a coarse-grained one that might form during slow cooling. This is conceptually similar to how quenching is used to harden steel.

The Critical Factor of Temperature

While time and cooling rate are important, sintering temperature is arguably the most critical variable. Higher temperatures accelerate the diffusion process, enabling faster densification and a greater increase in hardness. However, there is an optimal temperature for every material.

Understanding the Trade-offs

Achieving maximum hardness is not always the only goal. Aggressively tuning the sintering process can lead to undesirable side effects.

Hardness vs. Toughness

A fundamental principle in materials science is the trade-off between hardness and toughness. A very hard material is often more brittle, meaning it is more susceptible to fracturing under sudden impact. Optimizing for hardness might compromise the material's ability to absorb energy.

The Risk of Excessive Grain Growth

If the sintering temperature is too high or the time is too long, grains can grow excessively large. While initial grain growth is beneficial, oversized grains can sometimes lead to reduced strength and toughness, creating a weaker overall structure despite high density.

Dimensional Control

Sintering inherently involves shrinkage as the material densifies. Aggressive parameters that maximize hardness can also cause more significant and potentially less predictable changes in dimension, making it difficult to hold tight tolerances on the final part.

Tailoring the Process for Your Goal

The ideal sintering parameters depend entirely on the desired properties of the final component. You must balance competing requirements to achieve the best outcome.

- If your primary focus is maximizing hardness and strength: Employ higher sintering temperatures, longer hold times, and a rapid cooling rate.

- If your primary focus is balancing hardness with toughness: Optimize for full density without causing excessive grain growth, and consider using a more moderate, controlled cooling rate.

- If your primary focus is high dimensional accuracy: Use the minimum effective sintering parameters (time and temperature) required to achieve the target density, which will help minimize and control shrinkage.

Ultimately, mastering the sintering process provides direct control over the microstructure, allowing you to engineer materials with precisely the properties you need.

Summary Table:

| Parameter | Effect on Hardness |

|---|---|

| Sintering Time | Longer time increases hardness by promoting densification. |

| Cooling Rate | Faster cooling rate can increase hardness by refining grain structure. |

| Sintering Temperature | Higher temperature accelerates densification, increasing hardness (up to an optimal point). |

| Porosity | Reducing porosity is the primary mechanism for increasing hardness. |

Need precise control over your material's hardness and properties?

The sintering process is key to achieving the perfect balance of hardness, toughness, and dimensional accuracy for your components. At KINTEK, we specialize in providing the advanced lab equipment and expert consumables needed to master this critical thermal process.

Whether you are developing new materials or optimizing existing production, our solutions help you achieve superior results. Contact our experts today to discuss how we can support your laboratory's sintering and materials testing needs.

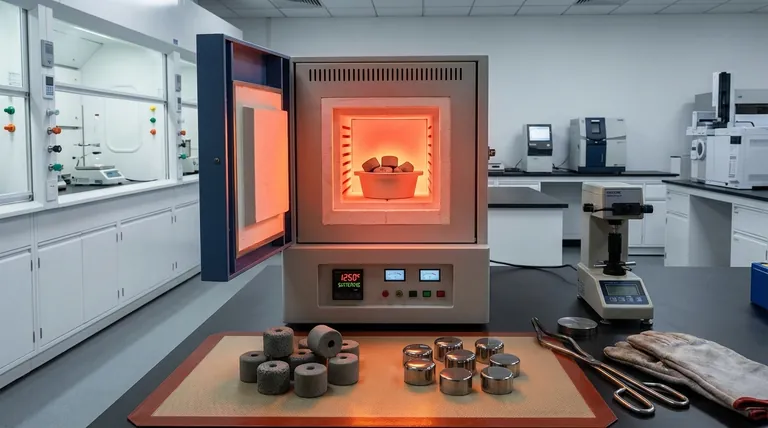

Visual Guide

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ Muffle Oven Furnace for Laboratory

- 1800℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- What is the primary purpose of using an orbital shaker during metal ion adsorption? Optimize PAF Performance

- How is a sample analysis done in FTIR? A Step-by-Step Guide to Reliable Results

- What is potassium bromide made of? Discover the Ionic Compound Powering Labs and Veterinary Care

- How is plasma created in sputtering process? Mastering Ionization for Superior Thin Films

- How is pyrolysis oil used? Unlocking its potential as a fuel and chemical feedstock

- What is film uniformity? The Key to Consistent Device Performance and Yield

- What are the advantages and disadvantages of bio-oil? A Guide to This Renewable Fuel

- What products are made by sintering? From Automotive Gears to Medical Implants