There is no fixed lifespan for a metal disk electrode. A well-maintained electrode can provide reliable service for many years, as its longevity is not determined by time but by its physical and electrical condition. The service life depends entirely on proper use, meticulous cleaning, and correct storage.

The lifespan of a metal disk electrode is not a countdown in months or years. Instead, it is a direct measure of its performance, which can be extended almost indefinitely through diligent maintenance and proper handling.

The Factors Defining Electrode Lifespan

An electrode's "health" is determined by two primary characteristics: its electrical conductivity and the integrity of its surface. Degradation in either of these areas signals that the electrode is approaching the end of its useful life.

Core Function: Electrical Conductivity

A metal disk electrode must have good electrical conductivity to function. This property, which varies by material (e.g., platinum, gold, silver), ensures the efficient transfer of current with minimal signal loss.

This translates to a low electrical resistance. A clean, undamaged electrode will have very low resistance, enabling fast response times and clear signal transmission.

The Impact of Contamination

Performance is compromised when the electrode surface becomes contaminated. Dirt, residual chemicals from previous experiments, or a layer of metal oxide will significantly increase the electrode's resistance.

This increased resistance interferes with signal transmission, degrades the quality of your data, and can render experimental results unreliable.

The Role of Physical Integrity

Beyond contamination, physical damage like deep scratches or pitting on the electrode's surface can alter its electrochemical properties. This damage can trap impurities and create non-uniform current distribution, leading to inconsistent results that cannot be fixed by simple cleaning.

Proactive Maintenance: The Key to Longevity

A consistent maintenance protocol is the single most important factor in maximizing the life of your electrode. Neglect is the primary cause of premature failure.

Immediate Post-Experiment Cleaning

The electrode must be cleaned immediately after each experiment. Use appropriate solvents, such as deionized water or ethanol, to thoroughly remove any residual electrolyte and impurities from the surface.

Correct Drying and Storage

After cleaning, the electrode should be carefully dried. It must then be stored in a dry, protected environment, shielded from humidity, high temperatures, and direct light.

Using the original storage case is the best practice, as it is designed to protect the sensitive electrode tip from accidental physical damage.

Common Failure Points and When to Replace

An electrode should be considered at the end of its life when it no longer provides reliable, reproducible results and cannot be restored through standard maintenance.

Irreparable Physical Damage

If the electrode surface is severely scratched, pitted, or otherwise damaged, and these defects cannot be corrected through polishing, it is time for a replacement. Such damage permanently compromises its performance.

Persistently High Resistance

When routine cleaning and polishing fail to lower the electrode's electrical resistance to its expected baseline, it indicates a more serious issue. This could be due to subsurface contamination or degradation of the electrode material itself.

Ensuring Experimental Reliability

Ultimately, if an electrode begins to produce inconsistent or non-reproducible data, it must be replaced. To ensure the integrity of your research, the new electrode should be of the same model and specifications.

How to Apply This to Your Work

Your approach to electrode care should align with your experimental priorities.

- If your primary focus is maximum reproducibility: Implement a strict, documented protocol for cleaning, inspection (both visual and resistance measurement), and storage after every single use.

- If your primary focus is extending lifespan for budgetary reasons: Prioritize immediate and thorough cleaning and proper storage, as this prevents the cumulative, minor contamination that leads to irreversible damage.

By treating your electrode as a precision instrument, you ensure its reliability and longevity.

Summary Table:

| Factor | Impact on Lifespan | Key Maintenance Action |

|---|---|---|

| Electrical Conductivity | Determines performance; low resistance is key. | Measure resistance regularly. |

| Surface Contamination | Major cause of failure; increases resistance. | Clean immediately after each use with deionized water/ethanol. |

| Physical Damage | Scratches or pitting ruin reproducibility. | Store in original case; handle with care. |

| Storage Conditions | Prevents degradation from environment. | Keep in a dry, protected place. |

Ensure your experiments are always accurate and reproducible. A well-maintained electrode is crucial for reliable data. KINTEK specializes in high-quality lab equipment and consumables, including durable metal disk electrodes designed for long-term performance. Let our experts help you select the right electrode and optimize your maintenance protocols. Contact KINTEK today to discuss your laboratory needs and enhance your research reliability.

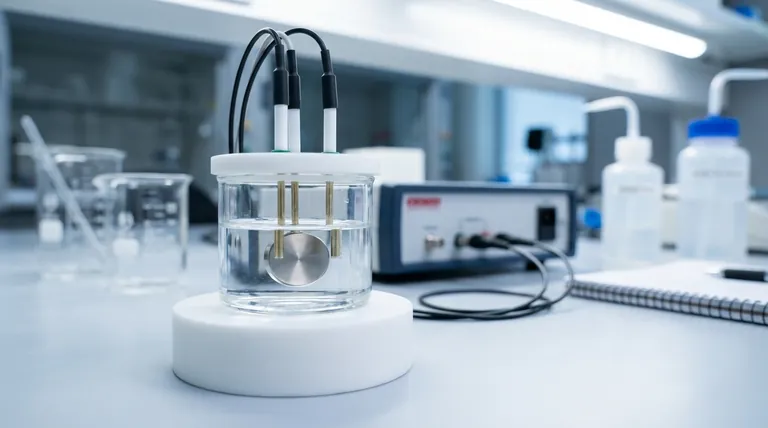

Visual Guide

Related Products

- Metal Disc Electrode Electrochemical Electrode

- Reference Electrode Calomel Silver Chloride Mercury Sulfate for Laboratory Use

- Rotating Platinum Disk Electrode for Electrochemical Applications

- Graphite Disc Rod and Sheet Electrode Electrochemical Graphite Electrode

- Copper Sulfate Reference Electrode for Laboratory Use

People Also Ask

- What is the expected lifespan of a copper sulfate reference electrode? Maximize Longevity with Proper Maintenance

- How does platinum coverage on titanium electrodes affect Kolbe electrolysis? Ensure 100% Integrity for Peak Yield.

- What is the basic structure of an electrode holder and the function of each part? Master the Key to Reliable Electrochemical Testing

- What is the primary function of metal electrodes in electrocoagulation? Optimize Your Microplastic Remediation Strategy

- Why is a glassy carbon electrode used as a substrate? The Key to Accurate Platinum Stability Testing

- What are the features of the Lead Dioxide-Titanium Oxygen Evolution Electrode? High Oxidizing Power & Durability

- What pre-treatment steps are necessary before using an RVC sheet? Ensure Reliable Performance and Data Integrity

- What is the purpose of performing anodic polarization on BDD electrodes? Ensure Accurate & Reproducible Research Results