At its core, a crucible furnace is a high-temperature device designed for a single, critical function: melting materials. It uses a container, the crucible, to hold a solid charge (like metal, glass, or alloys) and heats it until it transforms into a liquid state, ready for casting or further processing.

The true function of a crucible furnace is not just to generate heat, but to provide a controlled, contained environment for converting solid materials into a molten form. Its value lies in its simplicity, versatility, and precision for small-scale applications.

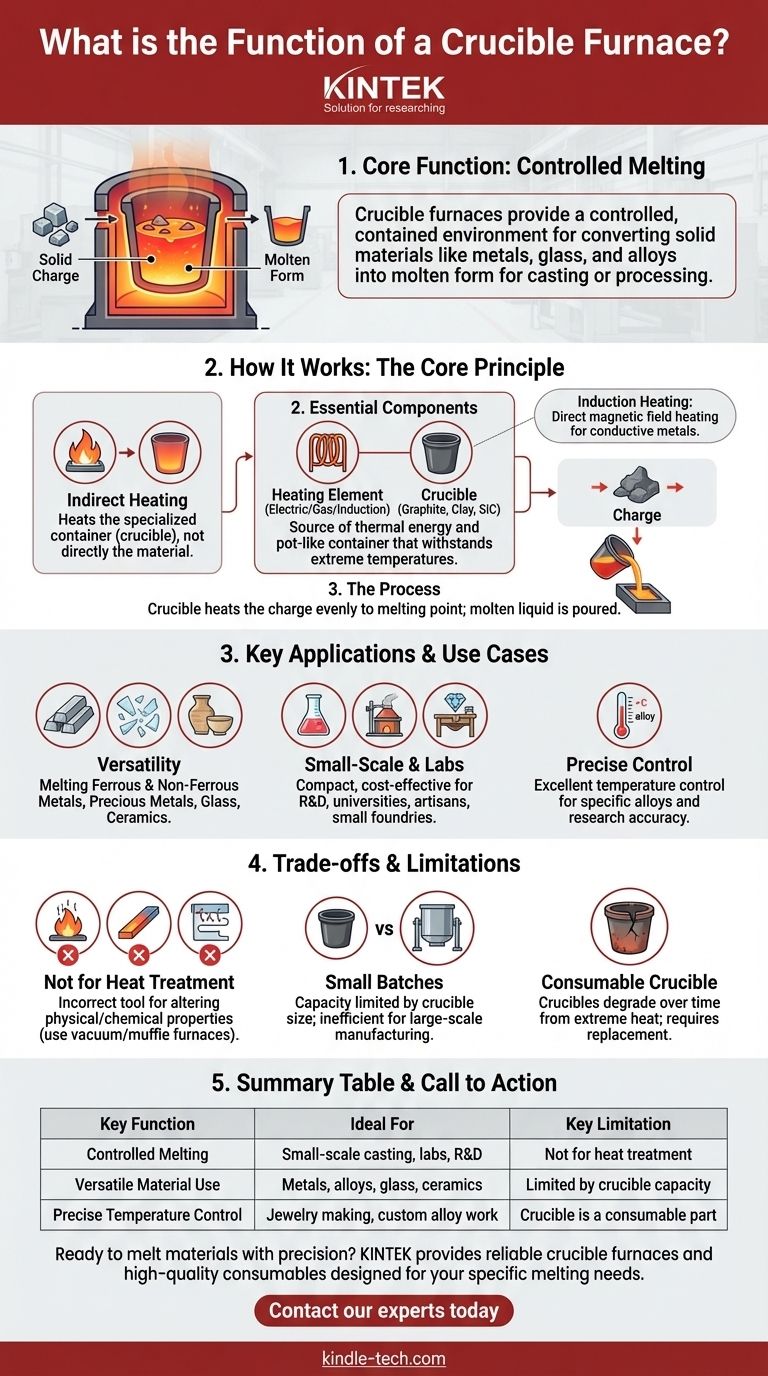

The Core Principle: How a Crucible Furnace Works

A crucible furnace operates on a straightforward principle of indirect heating. Instead of applying heat directly to the material, it heats a specialized container which then transfers that heat to the contents.

The Two Essential Components

Every crucible furnace is built around a heating element and a crucible. The heating element, often powered by electricity (resistance) or gas, is the source of thermal energy. The crucible is a pot-like container made from materials like graphite, clay, or silicon carbide, chosen for their ability to withstand extreme temperatures without reacting with the molten material inside.

The Melting Process

The process begins by placing the material to be melted, known as the "charge," inside the crucible. The heating element then heats the furnace chamber, and this heat is transferred to the crucible. The crucible, in turn, heats the charge evenly until it reaches its melting point. Once fully molten, the liquid can be carefully poured into a mold.

Methods of Heating

While gas and electric resistance are common, some crucible furnaces use induction heating. In this design, an induction coil creates a magnetic field that directly heats the metal charge within the crucible, functioning much like the secondary winding of a transformer. This method can offer faster and more efficient heating for conductive metals.

Key Applications and Use Cases

The design of the crucible furnace makes it exceptionally well-suited for specific tasks across various industries, from laboratories to artisan workshops.

Melting a Wide Range of Materials

One of the furnace's greatest strengths is its versatility. It is not limited to a single type of metal and can be used to melt ferrous and non-ferrous metals, precious metals, alloys, glass, and even some ceramics.

Small-Scale and Laboratory Settings

Due to their relatively compact size and cost-effectiveness, crucible furnaces are a staple in small foundries, university laboratories, and for jewelers or artists. They provide a practical means of melting materials without the massive infrastructure of industrial-scale furnaces.

Precise Temperature Control

Modern crucible furnaces offer excellent temperature control. This is critical when working with specific alloys that have narrow melting windows or when conducting experiments where temperature accuracy is essential for achieving desired material properties.

Understanding the Trade-offs and Limitations

To use a crucible furnace effectively, it's crucial to understand what it is—and what it isn't—designed to do.

Designed for Melting, Not Heat Treatment

A crucible furnace's primary function is melting. It is the wrong tool for processes like annealing (softening), tempering (toughening), curing, or brazing. These tasks require different types of specialized equipment, such as a vacuum furnace or a laboratory oven, which are designed to hold materials at specific temperatures for set times to alter their physical or chemical properties.

Primarily for Smaller Batches

The capacity of the crucible itself inherently limits the volume of material that can be processed in one cycle. This makes the furnace ideal for prototypes, custom work, or lab-scale production but inefficient for large-scale industrial manufacturing.

Crucible Durability

The crucible is a consumable component. Repeated exposure to extreme thermal cycles can cause it to degrade or crack over time. This represents an ongoing operational cost and requires careful handling to ensure safety and prevent failed melts.

Making the Right Choice for Your Goal

Selecting the correct heating equipment depends entirely on your end goal.

- If your primary focus is casting small metal parts or jewelry: A crucible furnace offers the precise control and ease of use needed for creating detailed molds and custom alloy work.

- If your primary focus is research, development, or material testing: The versatility and compact size of a laboratory crucible furnace make it ideal for experimenting with different materials and alloys on a manageable scale.

- If your primary focus is altering a material's properties through heat treatment: A crucible furnace is the incorrect tool; you need a dedicated laboratory, muffle, or vacuum furnace designed for processes like annealing, quenching, or tempering.

Ultimately, understanding a crucible furnace's function as a specialized melting tool is the key to leveraging its power effectively.

Summary Table:

| Key Function | Ideal For | Key Limitation |

|---|---|---|

| Controlled Melting | Small-scale casting, labs, R&D | Not for heat treatment (annealing, tempering) |

| Versatile Material Use | Metals, alloys, glass, ceramics | Limited by crucible capacity (small batches) |

| Precise Temperature Control | Jewelry making, custom alloy work | Crucible is a consumable part |

Ready to melt materials with precision?

Whether you're in a laboratory developing new alloys or a workshop creating custom jewelry, the right crucible furnace is key to your success. KINTEK specializes in lab equipment and consumables, providing reliable crucible furnaces designed for your specific melting needs.

Contact our experts today to find the perfect furnace for your application and ensure you have the high-quality consumables, like durable crucibles, to keep your operations running smoothly.

Visual Guide

Related Products

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Vertical Laboratory Tube Furnace

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- How does a quartz tube vacuum furnace contribute to the crystallization process of Ag-doped Li-argyrodite electrolytes?

- How to clean a tube furnace? A Step-by-Step Guide for Safe and Effective Maintenance

- What precautions should be taken when using a tube furnace? Ensure Safe, Effective High-Temperature Processing

- How is the temperature in a tube furnace measured and controlled? Master Precise Thermal Processing

- Why is a quartz tube furnace utilized in the thermal oxidation of MnCr2O4 coatings? Unlock Precise Selective Oxidation