The primary function of sintering is to transform a mass of powder into a solid, coherent object using heat. This process occurs at temperatures below the material's melting point, relying on atomic diffusion to fuse individual particles together, which increases the material's strength, density, and integrity.

Sintering allows us to create strong, solid components from metal or ceramic powders without having to melt them. This makes it an indispensable and energy-efficient tool for processing materials with extremely high melting points and for advanced manufacturing techniques like 3D printing.

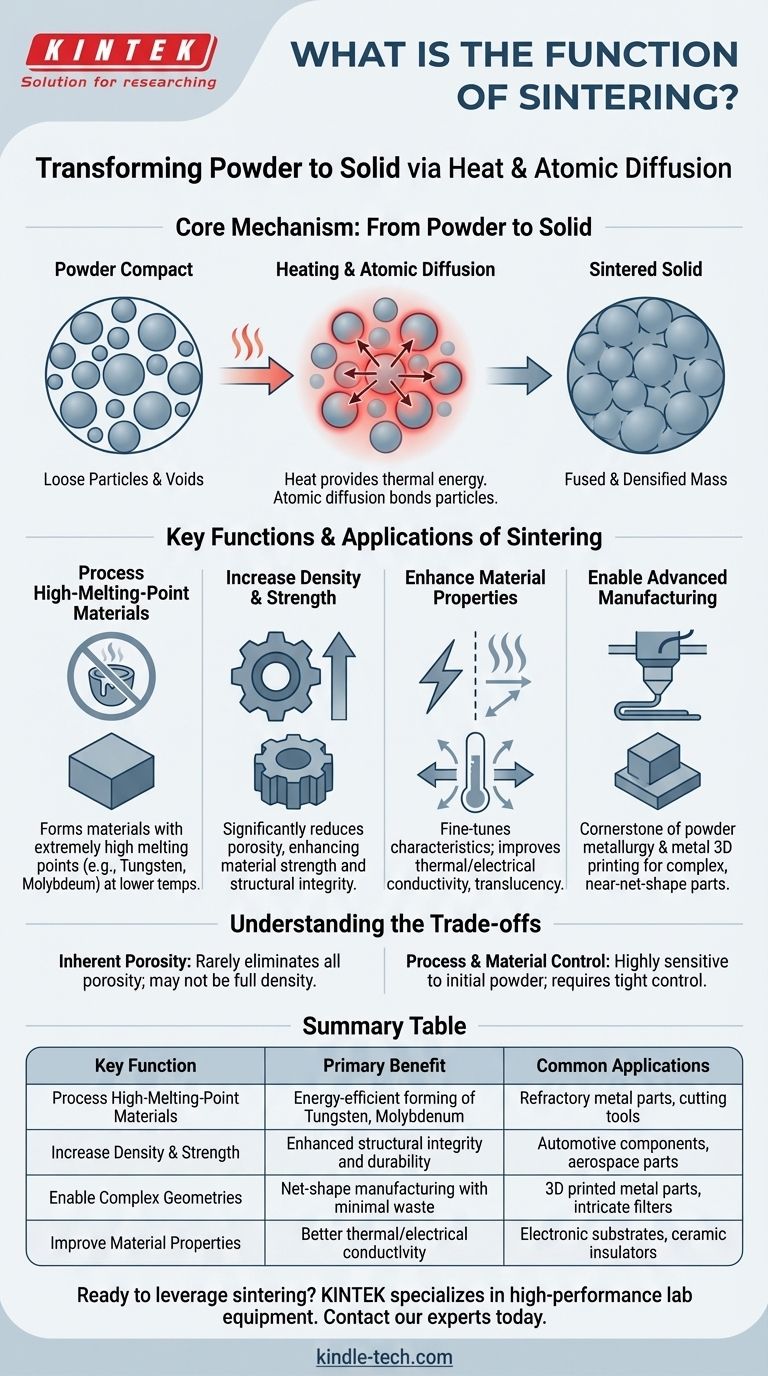

The Core Mechanism: From Powder to Solid

Sintering is fundamentally a thermal transformation process. It takes a compacted or loose collection of particles and uses controlled heating to bond them into a single, densified piece.

The Role of Heat and Pressure

Heat is the primary driver of sintering. It provides the necessary thermal energy for atoms within the particles to become mobile.

While not always required, pressure is often applied to press the powder particles into close contact, which reduces the distance atoms need to travel and accelerates the bonding process.

Atomic Diffusion: The Key to Fusion

Instead of melting, sintering relies on atomic diffusion. At elevated temperatures, atoms migrate across the boundaries of adjacent particles.

This atomic movement effectively fills the voids between particles and creates strong metallurgical bonds, fusing the separate grains into a single, solid mass with a more refined microstructure.

Key Functions and Applications of Sintering

Engineers and manufacturers choose sintering for several distinct and powerful advantages over other methods like casting.

Processing High-Melting-Point Materials

This is one of sintering's most critical functions. For metals like tungsten and molybdenum, which have extremely high melting points, melting them is impractical and prohibitively expensive.

Sintering allows these materials to be formed into solid, usable parts at much lower temperatures, saving significant energy and overcoming technical hurdles.

Increasing Material Density and Strength

The initial powder compact is porous. The sintering process significantly reduces this porosity by pulling the particles together.

Reducing the empty space between particles dramatically increases the object's overall density, which directly contributes to higher material strength and structural integrity.

Enhancing Material Properties

By controlling the sintering process, it's possible to fine-tune a material's final characteristics.

Proper sintering can significantly improve thermal and electrical conductivity, as the fused particle boundaries create a more efficient path for energy to travel. For some ceramics, it can even increase translucency.

Enabling Advanced Manufacturing

Sintering is a cornerstone of modern manufacturing, particularly in powder metallurgy and metal 3D printing.

It allows for the creation of complex, near-net-shape parts directly from a powder bed, minimizing waste and the need for subsequent machining.

Understanding the Trade-offs

While powerful, the sintering process has inherent characteristics that must be considered for any application.

Inherent Porosity

Although sintering significantly densifies a material, it rarely eliminates porosity completely. A sintered part may not be as fully dense as one that was cast from a liquid state.

This residual porosity can be a limiting factor for applications requiring the absolute maximum mechanical strength or hermetic sealing.

Process and Material Control

The final properties of a sintered part are highly sensitive to the characteristics of the initial powder, including particle size and shape.

Achieving consistent, repeatable results requires tight control over temperature, time, and atmospheric conditions during the entire sintering cycle.

Making the Right Choice for Your Goal

Selecting sintering depends entirely on the material you are using and the final properties you need to achieve.

- If your primary focus is working with high-temperature materials: Sintering is the most practical and energy-efficient method for forming parts from metals like tungsten.

- If your primary focus is creating complex, net-shape parts: Sintering, especially in 3D printing, excels at producing intricate designs with minimal material waste.

- If your primary focus is achieving specific material properties: Sintering provides a unique level of control over a part's final density, conductivity, and strength.

Ultimately, sintering serves as a foundational process for engineering advanced materials with precision and efficiency.

Summary Table:

| Key Function | Primary Benefit | Common Applications |

|---|---|---|

| Process High-Melting-Point Materials | Energy-efficient forming of tungsten, molybdenum | Refractory metal parts, cutting tools |

| Increase Density & Strength | Enhanced structural integrity and durability | Automotive components, aerospace parts |

| Enable Complex Geometries | Net-shape manufacturing with minimal waste | 3D printed metal parts, intricate filters |

| Improve Material Properties | Better thermal/electrical conductivity | Electronic substrates, ceramic insulators |

Ready to leverage sintering for your laboratory or manufacturing needs? KINTEK specializes in high-performance lab equipment and consumables for material processing. Whether you're working with advanced ceramics, metal powders, or developing new sintering protocols, our solutions deliver precise temperature control and consistent results. Contact our experts today to discuss how we can support your research and production goals with reliable sintering furnaces and accessories.

Visual Guide

Related Products

- Laboratory Rapid Thermal Processing (RTP) Quartz Tube Furnace

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Vertical Laboratory Tube Furnace

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- What is the primary function of an electric muffle furnace during CNT synthesis? Unlock High-Performance Catalysts

- How does a benchtop drying oven contribute to pectin-based films? Achieve Uniform Curing and Flexibility

- What is the function of a high-precision high-temperature furnace for 18 Ni (300) steel? Ensure Optimal Microstructure

- What is the difference between ashing and wet digestion? Choosing the Right Sample Prep Method

- How does a 400°C holding stage affect nickel-alumina sintering? Ensure Structural Integrity & High Density

- What happens in the muffle furnace? Achieve Pure, Uniform High-Temperature Processing

- Why is a high-temperature muffle furnace necessary for zeolite pretreatment? Achieve Superior Thermal Activation

- What is an ashing furnace? A Key Tool for Precise Inorganic Material Analysis