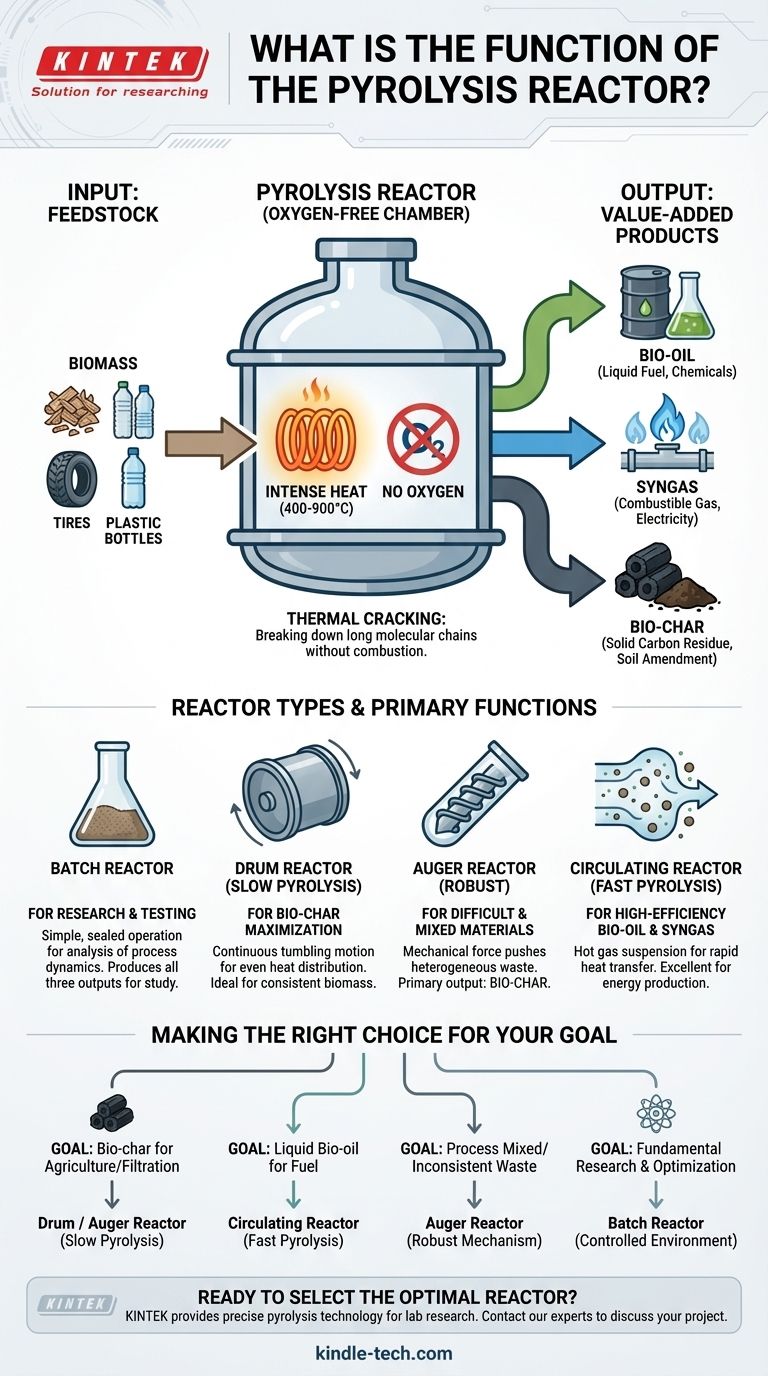

At its core, a pyrolysis reactor is a specialized, sealed chamber designed to thermally decompose organic material in the near-total absence of oxygen. Instead of burning waste, the reactor applies intense heat (typically 400-900°C) to break down large, complex molecules into smaller, more valuable components: a liquid fuel (bio-oil), a combustible gas (syngas), and a solid, carbon-rich residue (bio-char).

The fundamental function of a pyrolysis reactor is not to destroy waste but to chemically transform it. It acts as a controlled refinery, using heat and pressure—without combustion—to convert low-value materials like biomass, plastics, or tires into valuable energy products and chemical feedstocks.

The Core Principle: Thermal Cracking Without Oxygen

The entire function of a pyrolysis reactor hinges on one critical condition: the absence of oxygen. Preventing oxygen from entering the chamber ensures that the material does not burn. Instead, a different chemical process takes over.

What Happens Inside the Reactor

The intense heat causes the long molecular chains within the feedstock to vibrate violently and break apart, a process known as thermal cracking. This is similar to the technology used in petroleum refining but is applied to different materials.

The output of this process is always a mix of three primary products. The specific design of the reactor determines the ratio of these outputs.

The Three Primary Outputs

- Bio-oil (Pyrolysis Oil): A liquid fuel that can be refined for use in engines, boilers, or upgraded into higher-value chemicals.

- Syngas (Synthesis Gas): A mixture of combustible gases, primarily carbon monoxide and hydrogen. It can be used to generate heat and electricity, often to power the pyrolysis plant itself.

- Bio-char: A stable, solid material rich in carbon. It can be used as a soil amendment to improve fertility, as a filtration medium, or as a solid fuel.

How Different Reactors Achieve This Goal

While the core principle is the same, different reactor designs exist to optimize for specific feedstocks and desired outputs. The key difference lies in how they transfer heat and move material through the system.

Batch Reactors: For Research and Testing

A batch reactor is the simplest type. A fixed amount of material is loaded, the chamber is sealed, and the process runs from start to finish.

Because of this simple, controlled operation, they are most often used in laboratories to investigate the energy stability and reaction dynamics of the pyrolysis process.

Drum Reactors: For Slow Pyrolysis and Bio-char

Also known as a rotating drum reactor, this design uses a large, cylindrical drum that rotates continuously. This tumbling motion ensures even heat distribution throughout the material.

This design is well-suited for slow pyrolysis, a process that maximizes the production of bio-char.

Auger Reactors: For Difficult and Mixed Materials

An auger reactor uses a large, motor-driven screw to push feedstock through the heated chamber. Heat transfer relies on mechanical force and pressure rather than fluid dynamics.

This robust mechanism makes it exceptionally good at handling heterogeneous or difficult-to-process materials. Its primary output is typically bio-char, making it less ideal for bio-oil production.

Circulating Reactors: For High-Efficiency Energy Production

A circulating or fluidized-bed reactor uses a flow of hot gas to suspend and heat the feedstock particles, causing them to behave like a fluid. This method provides excellent heat transfer and is highly efficient.

This technology is used extensively in large-scale renewable energy and electricity generation applications where maximizing the yield of syngas or bio-oil is the primary goal.

Understanding the Trade-offs

No single reactor design is universally superior. The choice of reactor is a strategic decision based on the intended feedstock and the desired primary product.

Speed vs. Product Yield

The rate of heating directly impacts the final products. Slow pyrolysis processes, common in drum and auger reactors, favor the production of stable bio-char. In contrast, fast pyrolysis, often achieved in circulating reactors, maximizes the yield of liquid bio-oil and syngas.

Feedstock Flexibility vs. Output

An auger reactor offers superior flexibility, capable of processing inconsistent or bulky materials that would jam other systems. The trade-off is that it is primarily a bio-char producer. A circulating reactor is highly efficient but may require more uniform and prepared feedstock to operate correctly.

Scale and Purpose

Batch reactors are for analysis, not production. Continuous reactors like the drum, auger, and circulating types are designed for commercial-scale output, each optimized for a different operational goal.

Making the Right Choice for Your Goal

The function of a specific pyrolysis reactor is defined by the outcome it is engineered to produce.

- If your primary focus is creating bio-char for agriculture or filtration: A slow pyrolysis drum or auger reactor is the most direct and effective choice.

- If your primary focus is generating liquid bio-oil for fuel: A fast pyrolysis process, likely involving a circulating or fluidized-bed reactor, is necessary.

- If your primary focus is processing inconsistent, mixed solid waste: The robust mechanical design of an auger reactor provides the most reliable performance.

- If your primary focus is fundamental research and process optimization: A batch reactor offers the controlled, observable environment required for detailed analysis.

Ultimately, the reactor is the heart of the pyrolysis system, and selecting the correct design is the critical first step in successfully transforming waste into a valuable resource.

Summary Table:

| Reactor Type | Primary Function | Ideal Feedstock | Main Output(s) |

|---|---|---|---|

| Batch Reactor | Research & Testing | Small, uniform samples | All three products (for analysis) |

| Drum Reactor | Slow Pyrolysis | Biomass, consistent materials | Bio-char |

| Auger Reactor | Handling Difficult Materials | Mixed, bulky, or inconsistent waste | Bio-char |

| Circulating Reactor | Fast Pyrolysis | Uniform, prepared materials | Bio-oil & Syngas |

Ready to select the right pyrolysis reactor for your lab's waste-to-resource project? KINTEK specializes in lab equipment and consumables, providing the precise pyrolysis technology you need to transform biomass, plastics, and other materials into valuable energy products and chemical feedstocks. Our experts will help you choose the optimal reactor design—whether for bio-char, bio-oil, or syngas production—ensuring efficiency and reliability for your laboratory's unique needs. Contact us today to discuss your project and discover how KINTEK can enhance your research and development efforts!

Visual Guide

Related Products

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant

- Customizable High Pressure Reactors for Advanced Scientific and Industrial Applications

- Mini SS High Pressure Autoclave Reactor for Laboratory Use

- High Pressure Laboratory Autoclave Reactor for Hydrothermal Synthesis

- Stainless High Pressure Autoclave Reactor Laboratory Pressure Reactor

People Also Ask

- What are the different types of pyrolysis machines? Choose the Right System for Your Output

- What is a disadvantage of biomass energy? The Hidden Environmental and Economic Costs

- What are the reactions involved in pyrolysis of biomass? Unlock the Chemistry for Tailored Bio-Products

- What are the products of pyrolysis of biomass? Unlock Bio-Char, Bio-Oil, and Syngas

- What are the conditions for biomass pyrolysis? Optimize Temperature, Heating Rate & Time