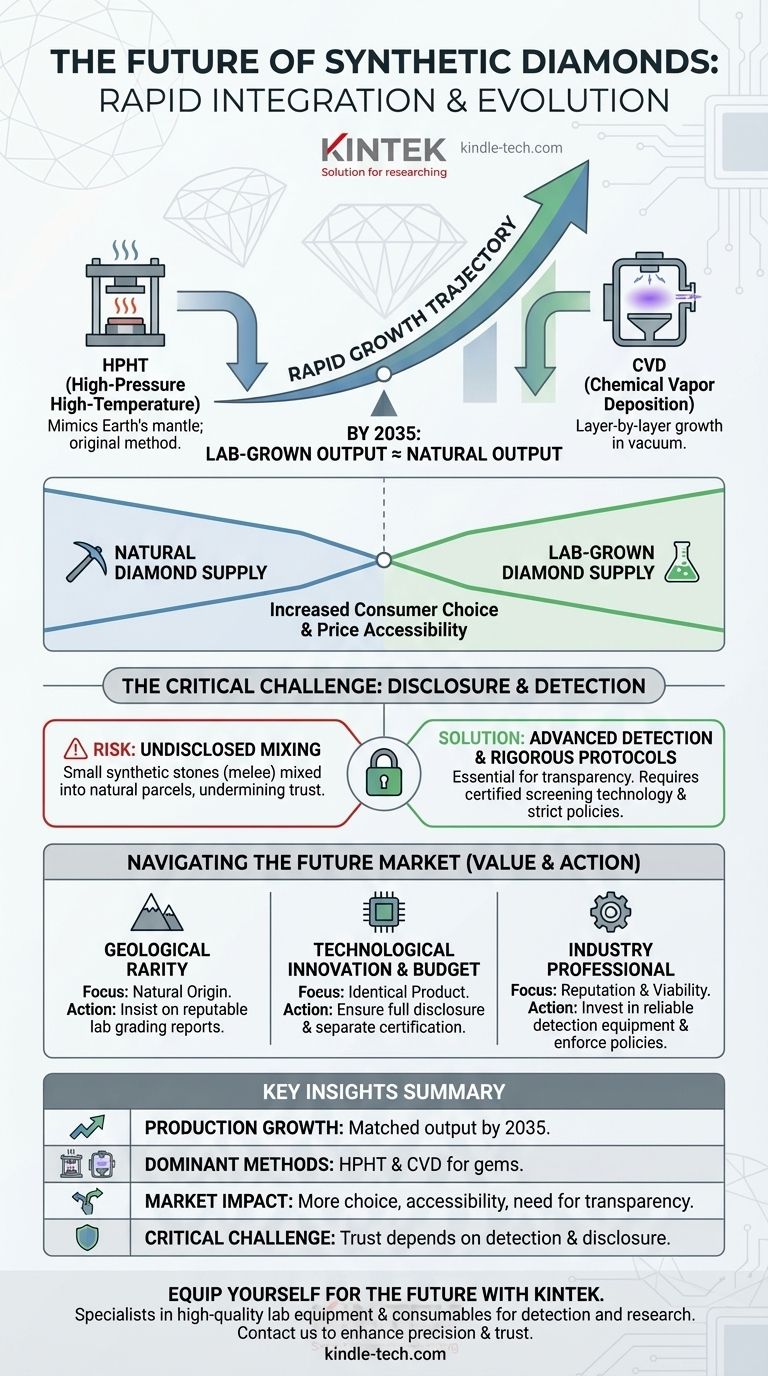

The future of synthetic diamonds is one of inevitable and rapid integration into the mainstream market. Driven by mature production methods like High-Pressure High-Temperature (HPHT) and Chemical Vapor Deposition (CVD), lab-grown diamond output is on a trajectory to match that of natural diamonds by 2035, fundamentally reshaping the industry for both consumers and professionals.

The core challenge ahead is not a question of whether synthetic diamonds will become a major market force—they already are. The future hinges on the industry's ability to manage this growth with absolute transparency, ensuring consumers can make informed choices based on clear distinctions of origin.

The Engine of Growth: Dominant Production Methods

The surge in synthetic diamond availability is a direct result of decades of technological refinement. Two primary methods have emerged as the commercial powerhouses for creating gem-quality stones.

High-Pressure, High-Temperature (HPHT)

HPHT is the original method of diamond synthesis. It essentially mimics the natural process within the Earth's mantle by subjecting a small diamond "seed" crystal and a carbon source to immense pressure and heat, causing the carbon to crystallize into a diamond.

Chemical Vapor Deposition (CVD)

The CVD method builds a diamond layer by layer. A seed crystal is placed in a vacuum chamber filled with carbon-rich gases, which are then ionized into plasma. This process breaks down the gas molecules, allowing carbon atoms to attach to the seed and grow a larger diamond crystal.

Other Emerging Techniques

While HPHT and CVD dominate, other methods exist. Detonation synthesis can create nanometer-sized diamond grains but is not used for gems. Similarly, using high-power ultrasound on graphite has been demonstrated in labs but has no current commercial application.

Projecting the Scale of Change

The growth of synthetic diamond production is not a gradual trend; it is an exponential one. This rapid increase in supply is creating a new dynamic in the global diamond market.

A Rapidly Closing Gap

According to industry analysis, the output of lab-grown diamonds is projected to equal the output of mined diamonds within the next decade. This represents one of the most significant shifts in the history of the gem and jewelry industry.

The Impact on Supply and Choice

This influx provides consumers with more choices than ever before. A lab-grown diamond is physically and chemically identical to a natural one, often available at a different price point, which democratizes access to high-quality stones.

The Critical Challenge: Disclosure and Detection

The greatest risk to the entire diamond market—both natural and synthetic—is not competition, but a loss of consumer trust. As production scales, the potential for undisclosed mixing becomes a primary concern.

The Problem of Undisclosed Mixing

Since 2013, reports have consistently emerged of small, undisclosed synthetic diamonds (melee) being mixed into parcels of natural diamonds. This deceptive practice undermines the value of natural stones and misleads the end consumer.

Why Transparency is Non-Negotiable

For the market to function effectively, there must be a clear and unbreakable chain of disclosure. The long-term value of both natural and synthetic diamonds depends entirely on consumers knowing exactly what they are buying. This requires advanced screening technology and rigorous industry protocols at every step.

Navigating the Future Diamond Market

The rise of synthetic diamonds necessitates a clear understanding of what defines value for different goals. The choice is no longer just about the stone itself, but the story and process behind it.

- If your primary focus is geological rarity and traditional value: Insist on grading reports from reputable gemological labs that confirm the natural origin of your diamond.

- If your primary focus is technological innovation and budget: A lab-grown diamond offers a physically identical product, but you must ensure it is sold with full disclosure and its own certification.

- If you are an industry professional: Investing in reliable detection equipment and enforcing strict disclosure policies is no longer optional; it is fundamental to maintaining your reputation and business viability.

The future of diamonds is not a battle between two products, but an evolution toward a more diverse, transparent, and technologically advanced market.

Summary Table:

| Aspect | Key Insight |

|---|---|

| Production Growth | Lab-grown diamond output projected to match natural diamonds by 2035. |

| Dominant Methods | HPHT and CVD are the primary technologies for gem-quality stones. |

| Market Impact | Increased consumer choice, price accessibility, and need for transparency. |

| Critical Challenge | Undisclosed mixing threatens trust; detection and disclosure are essential. |

Ready to navigate the evolving diamond market with confidence? Whether you're a jeweler needing reliable detection equipment or a researcher exploring advanced materials, KINTEK specializes in high-quality lab equipment and consumables to support your work with synthetic and natural diamonds. Contact us today to discover how our solutions can enhance your precision, efficiency, and trust in the industry!

Visual Guide

Related Products

- CVD Diamond for Thermal Management Applications

- Microwave Plasma Chemical Vapor Deposition MPCVD Machine System Reactor for Lab and Diamond Growth

- Cylindrical Resonator MPCVD Machine System Reactor for Microwave Plasma Chemical Vapor Deposition and Lab Diamond Growth

- CVD Diamond Domes for Industrial and Scientific Applications

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

People Also Ask

- Is biofuel a renewable energy source? Powering a Sustainable Future with Biomass

- Why is a high-performance laboratory magnetic stirrer necessary? Optimize Photocatalytic Degradation Results

- What are the limitations of XRF? Understanding Its Boundaries for Accurate Elemental Analysis

- What are the limitations of XRF analysis? Overcome Sample Prep Challenges for Accurate Results

- How does heat treatment affect surface roughness? Minimize Surface Degradation for Precision Parts

- What is the material of filter press? Why Reinforced Polypropylene is the Industry Standard

- How does a centrifuge work and for what purpose? Unlock the Power of Rapid Sample Separation

- What metals can be sintered? A Guide to Materials and Processes for Stronger Parts