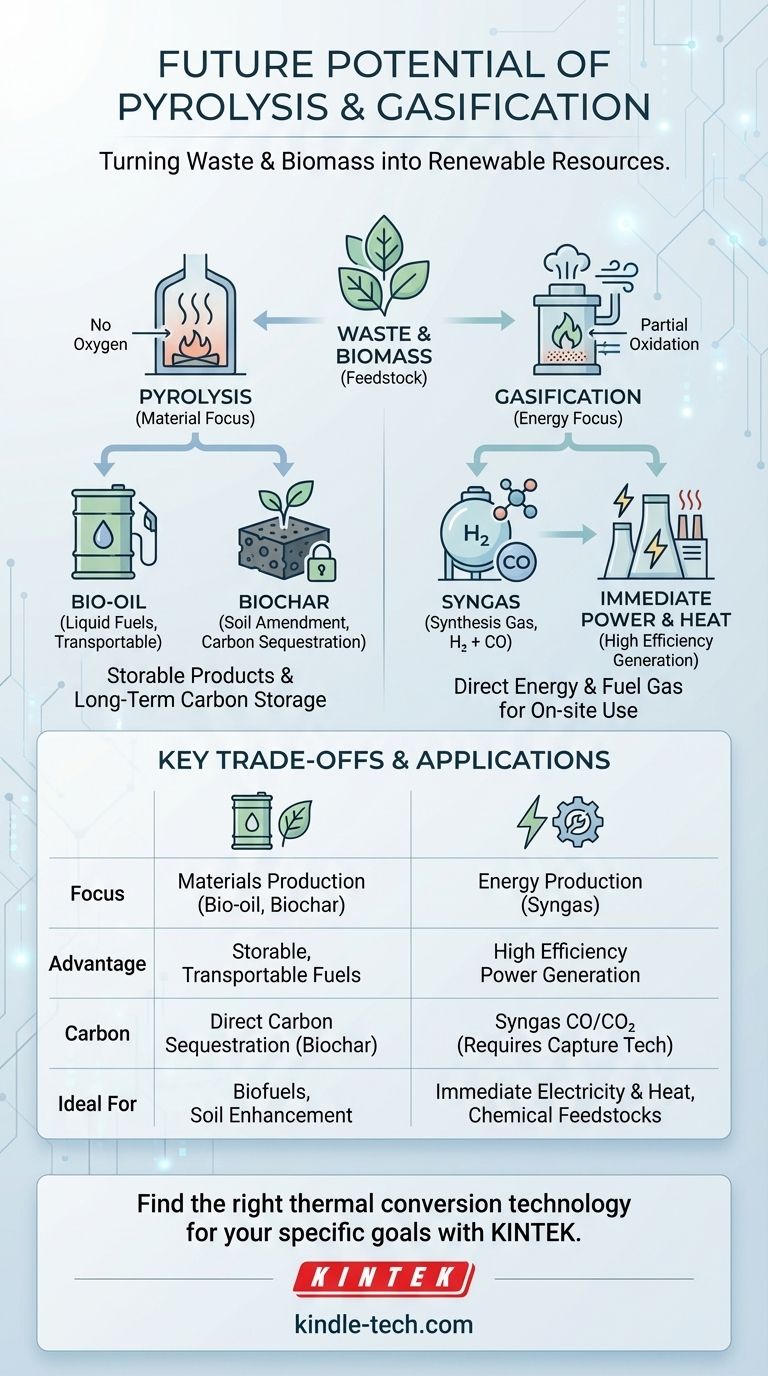

In short, the future potential of pyrolysis and gasification is immense because they are proven technologies for converting waste and biomass into valuable resources. They represent a critical shift away from fossil fuels by creating renewable energy, fuels, and soil-enhancing products. Pyrolysis is primarily geared toward producing liquid bio-oil and solid biochar, while gasification is optimized for generating electricity and heat with higher efficiency.

The core decision between these technologies is not about which is universally "better," but which is the right tool for a specific objective. Pyrolysis is a material-focused process creating storable products, while gasification is an energy-focused process for immediate power generation.

Pyrolysis: A Pathway to Liquid Fuels and Carbon Sequestration

Pyrolysis is a thermal decomposition process that heats organic materials, like biomass or plastic, in a near-total absence of oxygen. This prevents combustion and instead breaks down the material into new, valuable substances.

Key Output: Bio-oil

The primary liquid product, bio-oil, is a complex mixture of organic compounds. It can be thought of as a renewable, crude-like oil.

This bio-oil can be stored, transported, and upgraded into advanced transportation fuels. The growing demand for sustainable biofuels is a major driver for the expansion of pyrolysis technology.

Key Output: Biochar

The solid co-product, biochar, is a stable, carbon-rich material similar to charcoal. Its potential is twofold.

First, it serves as a powerful soil amendment, improving water retention and nutrient availability in agriculture. Second, and critically for the future, it is a form of carbon sequestration. The carbon locked in biochar remains stable in the soil for centuries, effectively removing it from the atmosphere.

Gasification: Maximizing Energy Extraction

Gasification uses a controlled, limited amount of oxygen or steam to partially oxidize organic material at high temperatures. It is designed to maximize the conversion of feedstock into a combustible gas.

Key Output: Synthesis Gas (Syngas)

The main product of gasification is synthesis gas, or syngas, which is a mixture composed primarily of hydrogen (H₂) and carbon monoxide (CO).

This gas is a clean and versatile fuel. It can be burned directly in gas engines or turbines to generate electricity and heat with high efficiency.

Primary Application: Power and Heat

As noted in industry analysis, gasification is generally considered more efficient than pyrolysis specifically for power generation. Its ability to convert the energy content of biomass directly into a fuel gas makes it a robust solution for on-site electricity and heat production.

Understanding the Trade-offs: Pyrolysis vs. Gasification

Choosing the right technology requires a clear understanding of their fundamental differences and what you want to achieve.

Energy Efficiency vs. Product State

Gasification is typically more energy-efficient for immediate electricity generation. It converts a higher percentage of the feedstock's energy directly into a usable fuel gas for power.

Pyrolysis, however, captures energy in storable and transportable forms (liquid bio-oil and solid biochar). This provides logistical flexibility that on-site gas-to-power systems lack, though upgrading the bio-oil to a final fuel requires additional energy.

Carbon Sequestration Potential

Pyrolysis offers a more direct and measurable pathway for carbon sequestration. The production of stable biochar that is returned to the soil physically locks carbon away for long periods.

In gasification, most of the feedstock's carbon is converted into carbon monoxide and carbon dioxide within the syngas. While this can be paired with carbon capture technologies, it is not an inherent co-product like biochar.

Application Focus

The core trade-off is one of application. Pyrolysis is fundamentally a materials production technology that creates valuable liquid and solid products. Gasification is fundamentally an energy production technology that creates a fuel gas for immediate use.

Making the Right Choice for Your Goal

Your strategic objective should guide your technological choice.

- If your primary focus is producing storable, transportable biofuels or sequestering carbon: Pyrolysis is the superior pathway due to its production of bio-oil and stable biochar.

- If your primary focus is maximizing immediate electricity or heat generation from biomass on-site: Gasification is generally the more efficient and direct solution.

- If your primary focus is creating chemical feedstocks like hydrogen or methanol: Gasification provides the direct input (syngas) needed for these chemical synthesis processes.

Ultimately, both technologies represent critical tools in the transition to a circular economy, turning waste streams into value streams.

Summary Table:

| Technology | Primary Outputs | Key Application |

|---|---|---|

| Pyrolysis | Bio-oil, Biochar | Storable biofuels, Carbon sequestration |

| Gasification | Syngas (H₂, CO) | Immediate electricity & heat generation |

Ready to find the right thermal conversion technology for your specific goals? Whether your project requires the material-focused outputs of pyrolysis or the energy-efficient power generation of gasification, KINTEK has the expertise and lab equipment to support your development. Contact our experts today to discuss how we can help you turn waste into valuable resources.

Visual Guide

Related Products

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant

- Customizable High Pressure Reactors for Advanced Scientific and Industrial Applications

- Mini SS High Pressure Autoclave Reactor for Laboratory Use

- High Pressure Laboratory Autoclave Reactor for Hydrothermal Synthesis

- Stainless High Pressure Autoclave Reactor Laboratory Pressure Reactor

People Also Ask

- What is the process of biomass fast pyrolysis? Turn Biomass into Bio-Oil in Seconds

- What are the products of pyrolysis of biomass? Unlock Bio-Char, Bio-Oil, and Syngas

- What are the conditions for biomass pyrolysis? Optimize Temperature, Heating Rate & Time

- What are the advantages of pyrolysis technology? Turn Waste into Profit and Reduce Emissions

- What are the different types of pyrolysis machines? Choose the Right System for Your Output