At its core, a muffle furnace transfers heat indirectly. The heat source—whether electric elements or fuel combustion—heats the walls of an enclosed chamber, or "muffle," and these hot walls then radiate heat uniformly onto the workpiece inside. This process prevents direct contact and contamination.

The defining characteristic of a muffle furnace is not just how it generates heat, but how it isolates it. Its design physically separates the heat source from the sample, relying on conduction and radiation to provide clean, uniform, and controllable high-temperature environments.

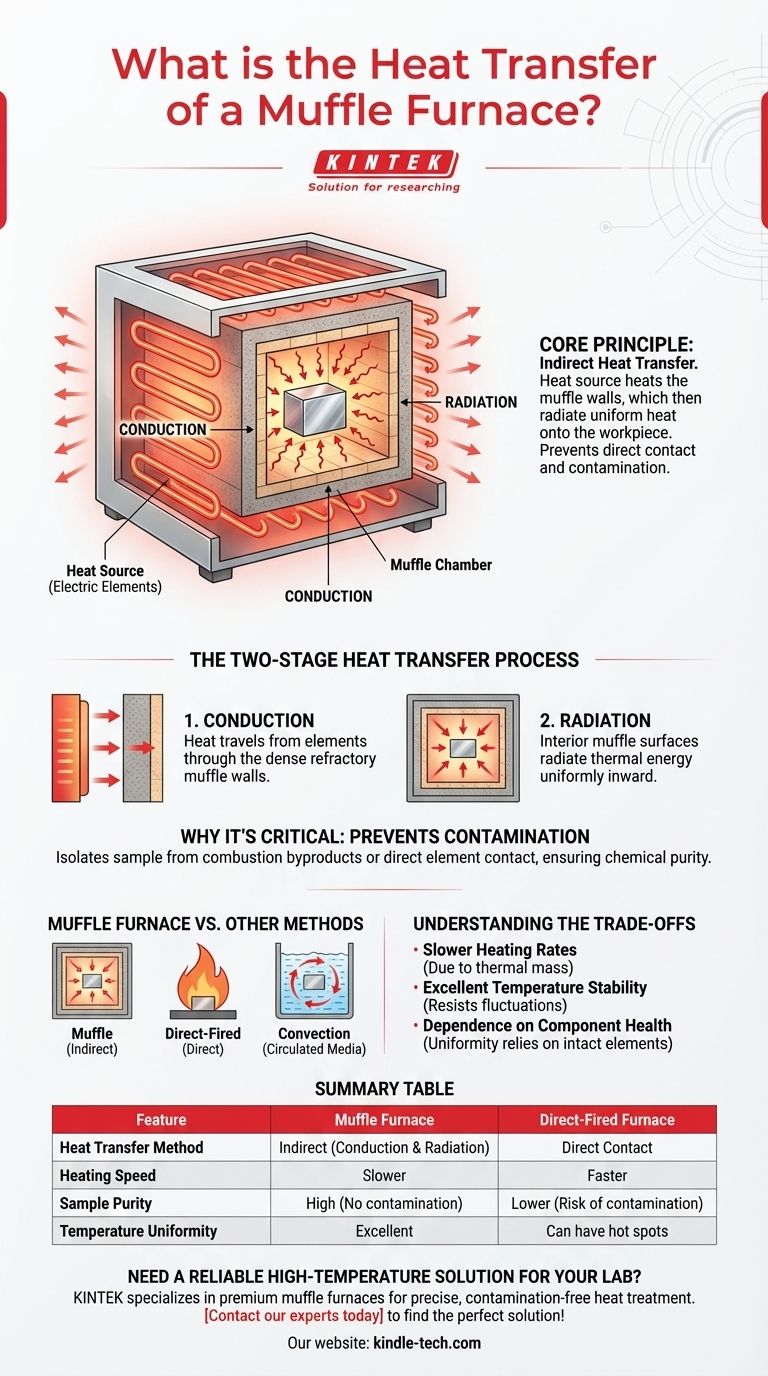

The Principle of Indirect Heating

The heat transfer in a muffle furnace is a deliberate, two-stage process designed for precision and purity. It's fundamentally different from a direct-fired kiln or a simple oven.

The "Muffle" Chamber

The key to this process is the muffle itself. This is a separate, sealed chamber, typically made of high-temperature refractory materials like silica and alumina firebricks.

The sample or workpiece is placed inside this muffle. The heating elements or combustion area remain outside of it.

The Two-Stage Heat Transfer Process

Heat travels from its source to the sample in two distinct steps:

- Conduction: Heat generated by the electric resistance heaters is first conducted through the dense refractory walls of the muffle.

- Radiation: Once the interior surfaces of the muffle reach the target temperature, they radiate thermal energy inward from all directions. This bathes the sample in uniform heat.

Why This Design Is Critical

The primary benefit of this indirect method is preventing contamination. By isolating the sample, it is protected from combustion byproducts in fuel-fired models or from direct interaction with the electric heating elements.

This ensures the chemical purity of the material being heated, which is essential for applications in laboratories, dentistry, and materials science.

How Muffle Furnaces Compare to Other Methods

Understanding the muffle furnace's heat transfer is clearer when contrasted with other common heating technologies.

Muffle vs. Direct-Fired Furnace

In a direct-fired furnace, the flame and hot gases from combustion come into direct contact with the workpiece. This is a very rapid and efficient way to transfer heat but introduces combustion byproducts directly onto the material's surface.

Muffle vs. Convection Furnace

Other furnaces, like a salt bath furnace, rely primarily on convection. A liquid or gas is heated and circulated to transfer heat to the workpiece. This is also very fast due to the intimate contact between the heating medium and the sample.

A muffle furnace has very little air to move, so at high temperatures, radiation becomes the dominant and far more effective mode of heat transfer within the chamber.

Understanding the Trade-offs

The indirect heating method offers unique advantages but also comes with inherent trade-offs that are important to recognize.

Slower Heating Rates

Because heat must first saturate and conduct through the thick refractory walls of the muffle, the overall heating process is slower than in direct-fired or convection-based systems.

Excellent Temperature Stability

The thermal mass of the refractory bricks that makes heating slower also provides a significant benefit: temperature stability. Once at temperature, the furnace resists fluctuations, providing a highly stable environment. This also means cool-down times are longer.

Dependence on Component Health

The entire principle relies on the uniform heating of the muffle walls. If heating elements are damaged or aged, they will create hot and cold spots on the muffle's interior surface, undermining the furnace's primary benefit of uniform radiation.

Making the Right Choice for Your Goal

To apply this knowledge, match the furnace's characteristics to your primary objective.

- If your primary focus is material purity and preventing contamination: A muffle furnace is the ideal choice due to its isolated chamber design.

- If your primary focus is precise temperature uniformity without hot spots: A muffle furnace excels because the entire inner chamber wall becomes the heat radiator.

- If your primary focus is the fastest possible heating speed: A direct-contact method like a salt bath or direct-fired furnace may be more suitable, but at the cost of cleanliness and uniformity.

By understanding this indirect heat transfer mechanism, you can leverage the muffle furnace for its unique strengths in high-purity, uniform-temperature applications.

Summary Table:

| Feature | Muffle Furnace | Direct-Fired Furnace |

|---|---|---|

| Heat Transfer Method | Indirect (Conduction & Radiation) | Direct Contact |

| Heating Speed | Slower | Faster |

| Sample Purity | High (No contamination) | Lower (Risk of contamination) |

| Temperature Uniformity | Excellent | Can have hot spots |

Need a reliable high-temperature solution for your lab?

KINTEK specializes in premium lab equipment, including muffle furnaces designed for precise, contamination-free heat treatment. Our furnaces ensure the material purity and temperature uniformity critical for your success in materials science, dentistry, and research.

Contact our experts today to find the perfect muffle furnace for your specific application!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1400℃ Muffle Oven Furnace for Laboratory

- 1800℃ Muffle Oven Furnace for Laboratory

- 1700℃ Muffle Oven Furnace for Laboratory

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- What is the construction of a muffle furnace? Discover the Precision Engineering for Pure, Controlled Heating

- How is a high-temperature muffle furnace utilized in SDC-carbonate synthesis? Master Calcination for High-Purity Powders

- What is the temperature of a high temperature furnace? A Guide to Selecting the Right Heat for Your Application

- How is a muffle furnace utilized to evaluate titanium-based composite materials? Master Oxidation Resistance Testing

- What is the inside material of a muffle furnace? Choose the Right Lining for Your Application

- What is the application of ashing? A Guide to Mineral Content Analysis

- What are the functions of graphite molds and annealing furnaces in the preparation of aluminoborosilicate glass bars?

- What is the operating temperature of the muffle furnace? Find Your Ideal Range for Lab Success