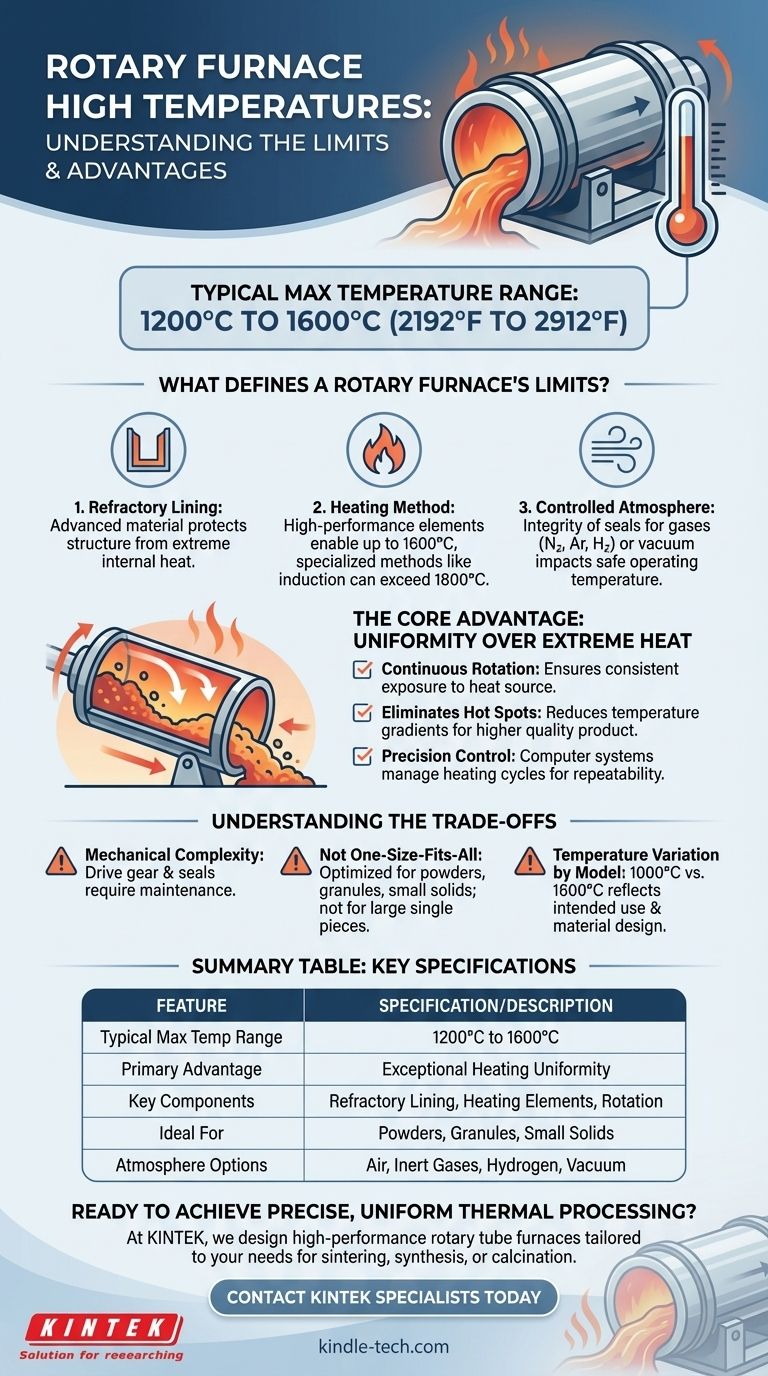

The maximum temperature of a rotary furnace typically ranges from 1200°C to 1600°C (2192°F to 2912°F). However, the exact temperature capability depends heavily on the specific model, its construction materials, and the industrial process for which it was designed, with some units operating at lower temperatures around 1000°C.

The operating temperature of a rotary furnace is not a single number but a specification tied to its core purpose. The design prioritizes creating an exceptionally uniform heating environment for processing flowing materials like powders and granules, a task achieved through constant rotation.

What Defines a Rotary Furnace's Temperature Limit?

A rotary furnace's ability to safely and consistently reach high temperatures is a result of its specialized construction. Several key components dictate its operational limits and overall performance.

The Role of Refractory Lining

The core of the furnace is a rotating barrel or tube. This component is lined with an advanced refractory material that serves as the primary thermal barrier, protecting the outer metal structure while withstanding extreme internal heat.

The Impact of the Heating Method

The heat source itself is a critical factor. Standard rotary tube furnaces use high-performance heating elements to achieve temperatures up to 1600°C. Other specialized heating technologies, such as induction, can enable even higher temperatures in different furnace types, sometimes exceeding 1800°C.

Controlled Atmosphere and Application

Many advanced processes require a controlled atmosphere. Rotary furnaces are often equipped to introduce specific gases like nitrogen, argon, or hydrogen, or to operate under a vacuum. The integrity of the seals and materials used for these features directly impacts the furnace's maximum safe operating temperature.

The Core Advantage: Uniformity Over Extreme Heat

While the high temperature is a key feature, the true value of a rotary furnace lies in its ability to heat materials with exceptional uniformity. This is a direct result of its dynamic design.

Continuous Rotation for Consistent Results

The furnace body is installed at a slight angle and rotates continuously around its axis. This motion causes the material inside—such as powders or granules—to tumble and mix thoroughly, ensuring every particle is exposed to the heat source evenly.

Eliminating Temperature Gradients

This constant mixing eliminates hot spots and reduces temperature gradients that can occur in static furnaces. The result is a more consistent and higher-quality end product, which is critical for applications in powder metallurgy, material blending, and chemical reactions.

Precision Temperature Control

Modern rotary furnaces are managed by sophisticated computer control systems. These systems allow for precise and repeatable control over the heating cycle, further enhancing the quality and reliability of the heat treatment process.

Understanding the Trade-offs

No single technology is perfect for every application. While highly effective, the design of a rotary furnace comes with specific considerations.

Mechanical Complexity

The drive gear, rotational seals, and tilting mechanism add mechanical complexity compared to a static box furnace. These components require regular maintenance to ensure reliability, especially when operating consistently at high temperatures.

Not a One-Size-Fits-All Solution

The design is optimized for processing materials that can flow or tumble, like powders, granules, and small solids. It is not suitable for heat-treating large, single-piece items that cannot move freely within the rotating barrel.

Temperature Variation by Model

The significant temperature differences noted across various models (e.g., 1000°C vs. 1600°C) reflect their intended use. A furnace designed for a lower-temperature chemical process will use different materials and heating elements than one built for high-temperature sintering, impacting its cost and capabilities.

Making the Right Choice for Your Goal

Selecting the correct furnace requires matching its specifications to your process requirements. The maximum temperature is a headline feature, but the context of your application is what truly matters.

- If your primary focus is high-purity chemical reactions: You need a model with excellent atmosphere control (gas inlets, vacuum capability) and precise temperature management, likely operating in the 1200°C+ range.

- If your primary focus is powder metallurgy or sintering: A high-temperature model capable of reaching 1600°C is often necessary to achieve the required material density and strength.

- If your primary focus is lower-temperature calcination or material blending: A more standard model operating up to 1000°C may be more cost-effective and perfectly sufficient for your needs.

Ultimately, matching the furnace's temperature capabilities and features to your specific material and process goal is the key to successful thermal processing.

Summary Table:

| Feature | Specification/Description |

|---|---|

| Typical Max Temperature Range | 1200°C to 1600°C (2192°F to 2912°F) |

| Primary Advantage | Exceptional heating uniformity for flowing materials |

| Key Components | Refractory lining, heating elements, rotation mechanism |

| Ideal For | Powders, granules, small solids requiring consistent heat treatment |

| Atmosphere Options | Air, inert gases (Nitrogen, Argon), hydrogen, vacuum |

Ready to achieve precise, uniform thermal processing for your materials?

At KINTEK, we specialize in designing and supplying high-performance rotary tube furnaces tailored to your specific application—whether it's high-temperature sintering, chemical synthesis, or material calcination. Our experts will help you select the ideal furnace with the right temperature range, atmosphere control, and features to ensure your success.

Contact our thermal processing specialists today to discuss your project requirements and get a customized solution!

Visual Guide

Related Products

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Heating Pyrolysis Plant

- Electric Rotary Kiln Small Rotary Furnace for Activated Carbon Regeneration

- Rotary Tube Furnace Split Multi Heating Zone Rotating Tube Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- How is the operational mode of bed motion selected for a rotary kiln? Optimize Heat Transfer and Material Homogeneity

- What is the meaning of rotary furnace? Achieve Superior Uniformity in Continuous Heat Treatment

- How does precision temperature control impact TiAl alloy sintering? Master Microstructure Development

- What is the principle of rotary kiln? Mastering Continuous Thermal Processing

- What are the equipment for pyrolysis laboratory? Choosing the Right Reactor for Your Research