While its origins are rooted in mid-20th century materials science, the core purpose of Hot Isostatic Pressing (HIP) has remained constant. It is a sophisticated manufacturing process that uses a combination of high temperature and uniform, high-pressure gas to eliminate internal porosity in materials, thereby dramatically improving their mechanical properties and reliability.

Hot Isostatic Pressing is fundamentally a method for upgrading materials. By subjecting parts to intense heat and isostatic (uniform) pressure within an inert gas environment, it closes internal voids and fuses particles together, creating a fully dense, high-performance final product.

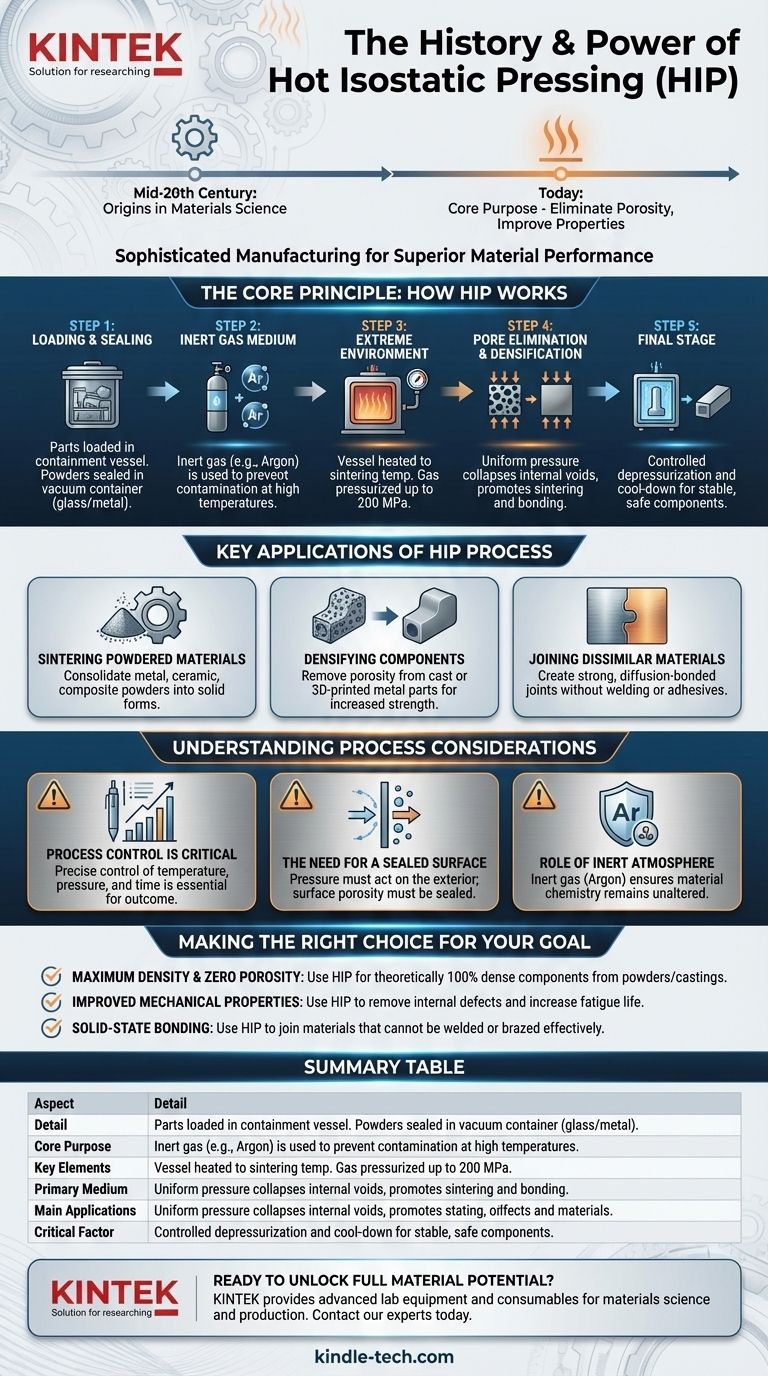

The Core Principle: How HIP Works

The HIP process is meticulously controlled to transform materials from a porous or powdered state into a solid, fully dense component. Each step is critical to achieving the desired outcome.

The Setup: Loading and Sealing

Parts are first loaded into a specialized high-pressure containment vessel. For powdered materials, such as silicon carbide, the powder is first sealed under a vacuum in a glass or metal container that will deform plastically during the process.

The Medium: Inert Gas Pressure

An inert gas, most commonly argon, is used as the pressure-transmitting medium. Using an inert gas is crucial because it prevents any chemical reaction or contamination with the material being processed, even at extreme temperatures.

The Environment: Temperature and Pressure

The vessel is heated to the target sintering temperature. Simultaneously, the inert gas is pumped in and pressurized, with pressures often reaching up to 200 MPa. This combination of heat and uniform pressure acts on the material from all directions.

The Outcome: Pore Elimination and Densification

The immense, uniform pressure collapses internal pores and voids within the material. For powdered metals or ceramics, this pressure promotes the diffusion and bonding between particles, a process known as sintering, resulting in a fully dense and solid part.

The Final Stage: Depressurization and Cooling

Once the desired density is achieved over a specific time, the process concludes. The vessel is carefully depressurized and undergoes a controlled cool-down period to ensure the components are stable and safe to handle.

Key Applications of the HIP Process

The unique ability of HIP to create perfectly dense materials makes it essential for high-performance applications where material failure is not an option.

Sintering Powdered Materials

HIP is used to consolidate metal, ceramic, or composite powders into a solid form. This is especially useful for materials that are difficult to machine or cast using traditional methods.

Densifying Existing Components

The process is widely used to remove porosity from cast or 3D-printed metal parts. Eliminating these microscopic internal voids significantly increases a component's strength, fatigue resistance, and overall reliability.

Joining Dissimilar Materials

The intense pressure and heat can be used to create a strong, diffusion-bonded joint between different materials or parts, forming a single, seamless component without the need for welding or adhesives.

Understanding the Process Considerations

While powerful, the HIP process is not a universal solution. Its effectiveness is dependent on careful control and understanding its inherent requirements.

Process Control is Critical

The outcome of the HIP cycle is highly sensitive to the precise control of temperature, pressure, and time. These variables must be closely monitored and tailored to the specific material and desired final properties.

The Need for a Sealed Surface

For HIP to work, the pressure must act on the material's exterior without the gas penetrating the part. This means that any porosity must be internal and not connected to the surface. For powdered materials, this is why they must be sealed in a container.

The Role of the Inert Atmosphere

The use of an inert gas like argon is non-negotiable. It ensures the material's chemistry remains unaltered during the high-temperature cycle, which is critical for maintaining the performance of sensitive alloys and ceramics.

Making the Right Choice for Your Goal

Deciding to use Hot Isostatic Pressing depends entirely on the performance requirements of your component.

- If your primary focus is achieving maximum material density and eliminating all porosity: HIP is the definitive process for creating theoretically 100% dense components from powders or castings.

- If your primary focus is improving the mechanical properties of a critical component: Using HIP to remove internal defects in cast or additively manufactured parts is a proven method to increase strength and fatigue life.

- If your primary focus is creating a solid-state bond between different parts or materials: HIP provides a powerful way to join materials that cannot be effectively welded or brazed.

Ultimately, Hot Isostatic Pressing serves as a powerful tool to engineer materials to their highest potential performance.

Summary Table:

| Aspect | Detail |

|---|---|

| Core Purpose | Eliminate internal porosity to improve mechanical properties |

| Key Elements | High temperature (up to sintering temp) & isostatic gas pressure (up to 200 MPa) |

| Primary Medium | Inert gas (e.g., Argon) to prevent contamination |

| Main Applications | Sintering powders, densifying cast/3D-printed parts, diffusion bonding |

| Critical Factor | Precise control of temperature, pressure, and time |

Ready to unlock the full potential of your materials? KINTEK specializes in providing advanced lab equipment and consumables for materials science and production. Whether you are researching or manufacturing high-performance components, our expertise in processes like Hot Isostatic Pressing can help you achieve superior density, strength, and reliability. Contact our experts today to discuss how we can support your laboratory's specific needs and drive your projects forward.

Visual Guide

Related Products

- Warm Isostatic Press WIP Workstation 300Mpa for High Pressure Applications

- Warm Isostatic Press for Solid State Battery Research

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Automatic Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

- Automatic High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

People Also Ask

- What is HIP treatment for metal? Eliminate Internal Defects for Superior Part Performance

- What are some of the attractive properties of hot isostatic pressed products? Achieve Perfect Density and Superior Performance

- What is the principle of hot isostatic pressing? Achieve 100% Density and Superior Performance

- Is hot isostatic pressing a heat treatment? A Guide to Its Unique Thermomechanical Process

- How much energy does hot isostatic pressing consume? Unlock Net Energy Savings in Your Process