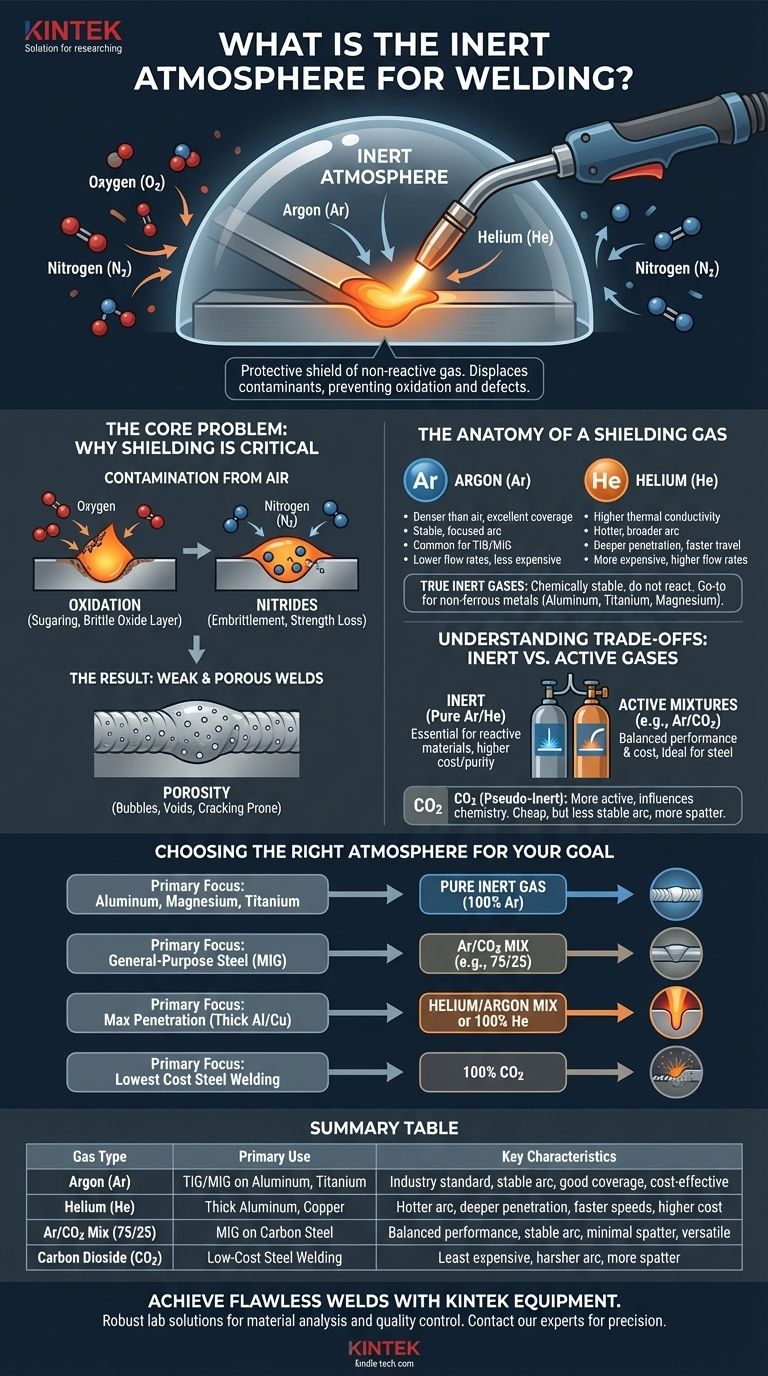

In welding, an inert atmosphere is a protective shield of non-reactive gas that surrounds the molten weld pool. The most common inert gases used for this purpose are argon and helium. This shield is critical because it displaces oxygen, nitrogen, and other contaminants from the ambient air that would otherwise react with the molten metal and compromise the quality of the weld.

The core purpose of an inert atmosphere is to act as a barrier, protecting the structurally vulnerable molten metal from atmospheric contamination. This protection is the deciding factor between a strong, clean weld and a weak, defective one.

The Core Problem: Why Shielding is Non-Negotiable

At the extreme temperatures of welding, molten metal is highly reactive. Exposing it to the open air, which is roughly 78% nitrogen and 21% oxygen, is a recipe for failure.

Contamination from the Air

Oxygen is the primary enemy of a clean weld, causing rapid oxidation (or "sugaring" in stainless steel), which creates a brittle, flaky oxide layer.

Nitrogen can also dissolve into the molten weld pool, especially in steels, leading to the formation of nitrides and causing embrittlement and a significant loss of strength.

The Result: Weak and Porous Welds

When these atmospheric gases are absorbed into the weld, they often get trapped as the metal cools and solidifies.

This creates tiny bubbles and voids within the weld bead, a defect known as porosity. A porous weld is fundamentally weak, full of stress points, and prone to cracking under load.

The Anatomy of a Shielding Gas

To prevent these defects, welders use a continuous flow of a shielding gas to create a localized, protective atmosphere around the arc and the weld pool. These gases fall into two main categories.

True Inert Gases: Argon and Helium

Inert gases are chemically stable and do not react with other elements, even at the high temperatures of a welding arc.

As noted in your references, argon (Ar) and helium (He) are the two principal inert gases used in welding. They are the go-to choice for welding non-ferrous metals like aluminum, magnesium, and titanium, which are extremely sensitive to contamination.

Argon: The Industry Standard

Argon is denser than air, meaning it provides excellent coverage over the weld area with lower flow rates. It also promotes a stable, focused arc and is less expensive than helium, making it the most common inert shielding gas for TIG and MIG welding.

Helium: The High-Performance Option

Helium has higher thermal conductivity than argon. This creates a hotter, broader arc that allows for deeper penetration and faster travel speeds, which is particularly useful for welding thick sections of material, especially aluminum and copper. It is, however, more expensive and requires higher flow rates.

Understanding the Trade-offs: Inert vs. Active Gases

While pure inert gases are essential for some materials, they are not the only option. In many common applications, particularly for steel, mixtures involving active gases are preferred.

The Role of "Pseudo-Inert" Gases

Your references mention carbon dioxide (CO2) as a "pseudo-inert" gas. In the welding industry, CO2 is more commonly classified as an active gas.

While it doesn't react with the molten weld pool in the same way as oxygen, it does react within the high heat of the welding arc, slightly breaking down and influencing the weld chemistry. It is not suitable for highly reactive metals like aluminum.

Why Mix Gases?

For welding carbon steel, pure argon can result in a weld bead profile that is tall and narrow. Adding a small percentage of CO2 (e.g., a 75% Argon / 25% CO2 mix) flattens the bead profile, improves penetration, and creates a more stable arc, resulting in a better overall weld with less spatter.

The Cost vs. Purity Equation

Pure CO2 is the cheapest shielding gas, but it produces a less stable arc and more spatter than an argon mix. Pure argon is necessary for non-ferrous metals but is more expensive. Argon/CO2 blends offer a balance of performance and cost that is ideal for most steel fabrication.

Choosing the Right Atmosphere for Your Goal

Selecting the correct shielding gas is not just a technical detail; it is a fundamental decision that dictates weld quality, appearance, and cost.

- If your primary focus is welding aluminum, magnesium, or titanium: You must use a pure inert gas, with 100% argon being the most common and effective choice.

- If your primary focus is general-purpose steel fabrication (MIG): A mix of 75% argon and 25% CO2 is the industry standard for a clean weld, stable arc, and minimal spatter.

- If your primary focus is maximum penetration on thick aluminum or copper: A helium/argon mixture or pure helium will provide the necessary heat input for a sound weld.

- If your primary focus is the lowest possible cost for steel welding: 100% CO2 can be used, but you must be prepared to manage a harsher arc and more post-weld cleanup.

Ultimately, the right atmosphere is the one that reliably protects your weld from the specific contaminants that threaten it.

Summary Table:

| Gas Type | Primary Use | Key Characteristics |

|---|---|---|

| Argon (Ar) | TIG/MIG on Aluminum, Titanium | Industry standard, stable arc, good coverage, cost-effective |

| Helium (He) | Thick Aluminum, Copper | Hotter arc, deeper penetration, faster speeds, higher cost |

| Ar/CO2 Mix (e.g., 75/25) | MIG on Carbon Steel | Balanced performance, stable arc, minimal spatter, versatile |

| Carbon Dioxide (CO2) | Low-Cost Steel Welding | Least expensive, harsher arc, more spatter |

Achieve Flawless Welds with the Right Equipment

Just as the correct shielding gas is critical for weld integrity, using reliable, high-performance lab equipment is essential for your research and quality control processes.

KINTEK specializes in providing robust lab equipment and consumables that meet the demanding needs of modern laboratories. Whether you are conducting material analysis, testing weld integrity, or developing new alloys, our products are designed to deliver precision and durability.

Let us help you enhance your lab's capabilities. Contact our experts today to find the perfect solution for your laboratory needs and ensure your processes are as protected and precise as your best welds.

Visual Guide

Related Products

- 1700℃ Controlled Atmosphere Furnace Nitrogen Inert Atmosphere Furnace

- 1200℃ Controlled Atmosphere Furnace Nitrogen Inert Atmosphere Furnace

- Controlled Nitrogen Inert Hydrogen Atmosphere Furnace

- 1400℃ Controlled Atmosphere Furnace with Nitrogen and Inert Atmosphere

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- Can nitrogen be used for brazing? Key Conditions and Applications Explained

- What gases are used in inert atmospheres? Choose the Right Gas for Non-Reactive Environments

- What is the purpose of using an atmosphere-controlled heating furnace for Cu reduction? Achieve Active Catalytic States

- What is the purpose of inert atmosphere? A Guide to Protecting Your Materials and Processes

- What is the role of an atmosphere-controlled tube furnace in Cu-Mo sintering? Achieve High-Purity Densification