At its core, ion beam sputtering (IBS) is a high-precision thin film deposition technique. It uses a focused beam of energetic ions, typically from an inert gas like argon, to physically dislodge atoms from a source material, known as a target. These sputtered atoms then travel through a vacuum and condense onto a component, or substrate, forming an exceptionally dense and uniform thin film.

The critical distinction of ion beam sputtering is its use of a dedicated, independent ion source. This separation of ion generation from the target material provides unparalleled control over the deposition process, prioritizing film quality and precision above all else.

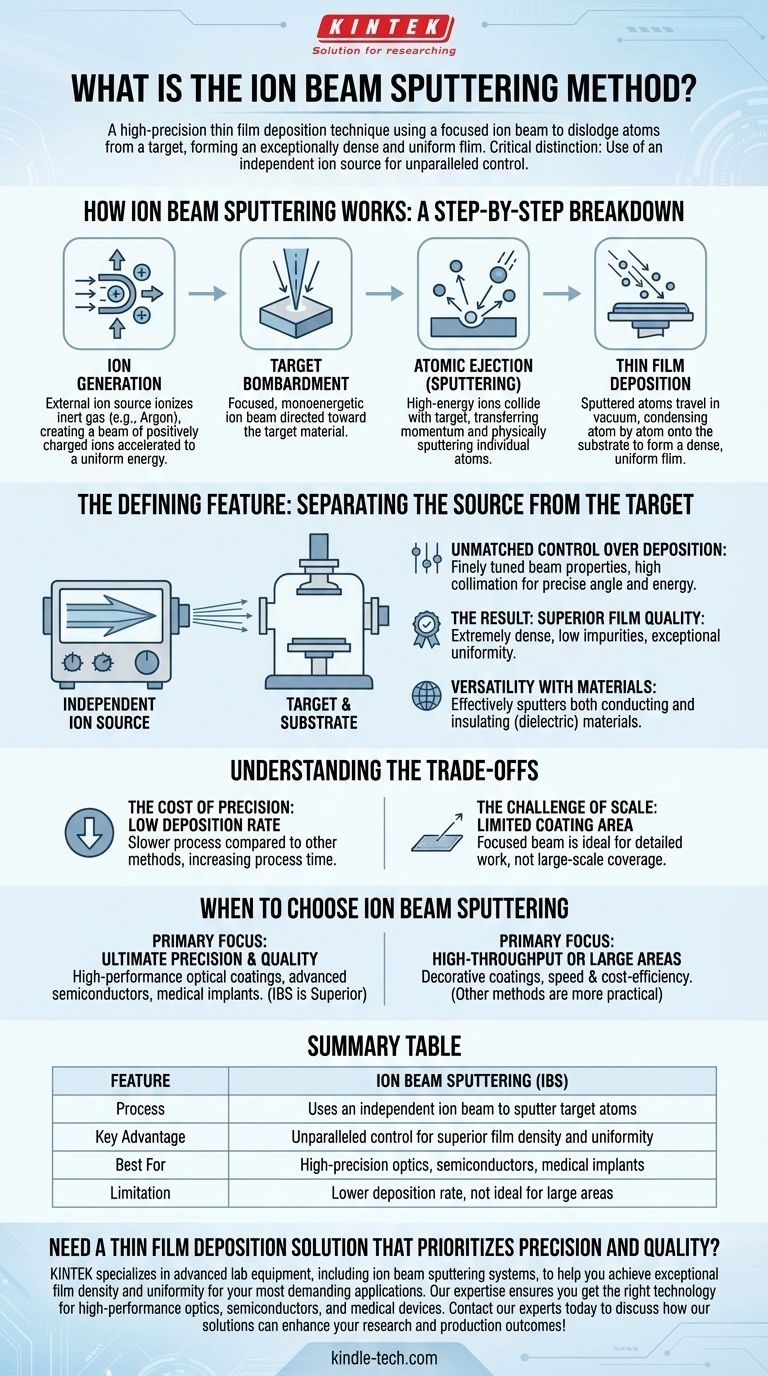

How Ion Beam Sputtering Works: A Step-by-Step Breakdown

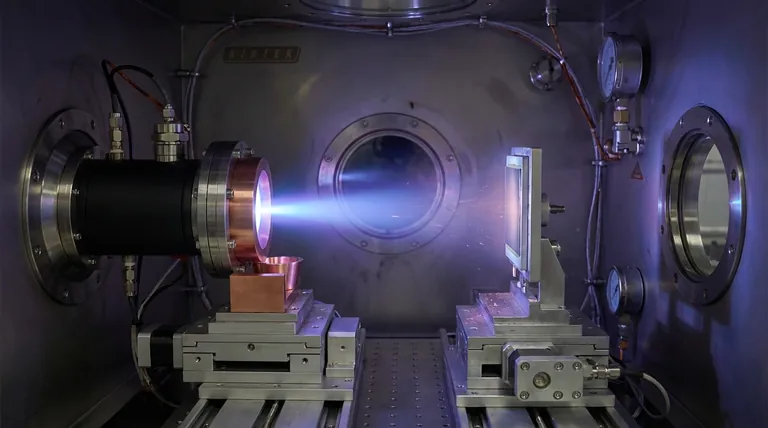

The IBS process occurs within a high-vacuum chamber to ensure the purity of the final film by preventing contamination from atmospheric gases. The entire operation can be broken down into four fundamental stages.

Step 1: Ion Generation

An external ion source ionizes an inert gas, such as argon. This creates a beam of positively charged ions that are accelerated to a specific, uniform energy level.

Step 2: Target Bombardment

This focused, monoenergetic (single-energy) ion beam is directed toward the target, which is a block of the material you wish to deposit (e.g., a metal or a dielectric).

Step 3: Atomic Ejection (Sputtering)

The high-energy ions collide with the target surface, transferring their momentum. This impact physically knocks off, or sputters, individual atoms from the target material.

Step 4: Thin Film Deposition

The sputtered atoms travel in a straight line through the vacuum and land on the substrate. They gradually build up, atom by atom, to form a thin, dense, and highly controlled film.

The Defining Feature: Separating the Source from the Target

The true value of IBS lies in its unique architecture. Unlike standard sputtering methods where the target is also the cathode within a plasma, IBS decouples these functions. This separation is the source of its primary advantages.

Unmatched Control Over Deposition

Because the ion beam is generated independently, its properties can be finely tuned without affecting the target. The beam is highly collimated, meaning the ions travel in a near-perfect parallel path. This gives engineers precise control over the angle of deposition and the energy of the bombarding ions.

The Result: Superior Film Quality

This high degree of control directly translates into films with superior characteristics. IBS films are known for being extremely dense, with low impurity levels and exceptional uniformity. This makes the method ideal for applications where material properties are critical.

Versatility with Materials

Since the target is not part of the electrical circuit generating the ions, IBS can effectively sputter both electrically conducting and insulating (dielectric) materials. This offers a significant advantage over methods that require the target to act as an electrode.

Understanding the Trade-offs

No technology is without limitations. The precision of IBS comes at a cost, and understanding these trade-offs is essential for proper application.

The Cost of Precision: Low Deposition Rate

The deliberate, highly controlled nature of IBS makes it a much slower process compared to other methods like magnetron sputtering. The rate at which material is deposited is significantly lower, increasing process time.

The Challenge of Scale: Limited Coating Area

The focused, narrow ion beam is excellent for precision work but poorly suited for coating large surface areas uniformly. While systems can be designed to accommodate larger parts, IBS is fundamentally a tool for detailed work, not large-scale coverage.

When to Choose Ion Beam Sputtering

Your choice of deposition technology should be driven entirely by your end goal. The decision to use IBS hinges on a clear trade-off between quality and throughput.

- If your primary focus is ultimate precision and film quality: For applications like high-performance optical coatings, advanced semiconductor devices, or medical implants where material integrity is non-negotiable, IBS is often the superior choice.

- If your primary focus is high-throughput or coating large areas: For decorative coatings or applications where speed and cost-efficiency are more important than absolute film density, other methods like magnetron sputtering are more practical.

Ultimately, choosing ion beam sputtering is a strategic decision to sacrifice speed for an unparalleled level of control and quality.

Summary Table:

| Feature | Ion Beam Sputtering (IBS) |

|---|---|

| Process | Uses an independent ion beam to sputter target atoms |

| Key Advantage | Unparalleled control for superior film density and uniformity |

| Best For | High-precision optics, semiconductors, medical implants |

| Limitation | Lower deposition rate, not ideal for large areas |

Need a thin film deposition solution that prioritizes precision and quality?

KINTEK specializes in advanced lab equipment, including ion beam sputtering systems, to help you achieve exceptional film density and uniformity for your most demanding applications. Our expertise ensures you get the right technology for high-performance optics, semiconductors, and medical devices.

Contact our experts today to discuss how our solutions can enhance your research and production outcomes!

Visual Guide

Related Products

- Electron Beam Evaporation Coating Oxygen-Free Copper Crucible and Evaporation Boat

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Laboratory Vortex Mixer Orbital Shaker Multifunctional Rotation Oscillation Mixer

People Also Ask

- What is chemical vapor deposition in semiconductors? The Atomic-Scale Engine of Modern Electronics

- What is a process used to deposit thin films? A Guide to PVD vs. CVD Methods

- What is CVD process in semiconductor? A Guide to Building Microchips from Gas

- What role does a gas control system play in the formation of alternating metal-ceramic structures? Master Cermet Coating

- What role does a vacuum Chemical Vapor Deposition (CVD) system play in the production of large-area graphene films?

- What is the deposition process of fabrication? A Guide to PVD & CVD Thin-Film Techniques

- What is the physics behind the magnetron sputtering? Harnessing Plasma for Superior Thin Films

- How are tools coated with diamond? Achieve Superior Hardness and Low Friction for Your Tools