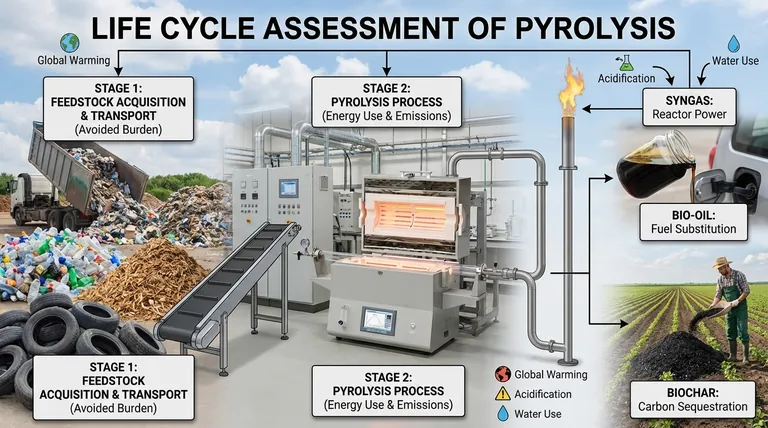

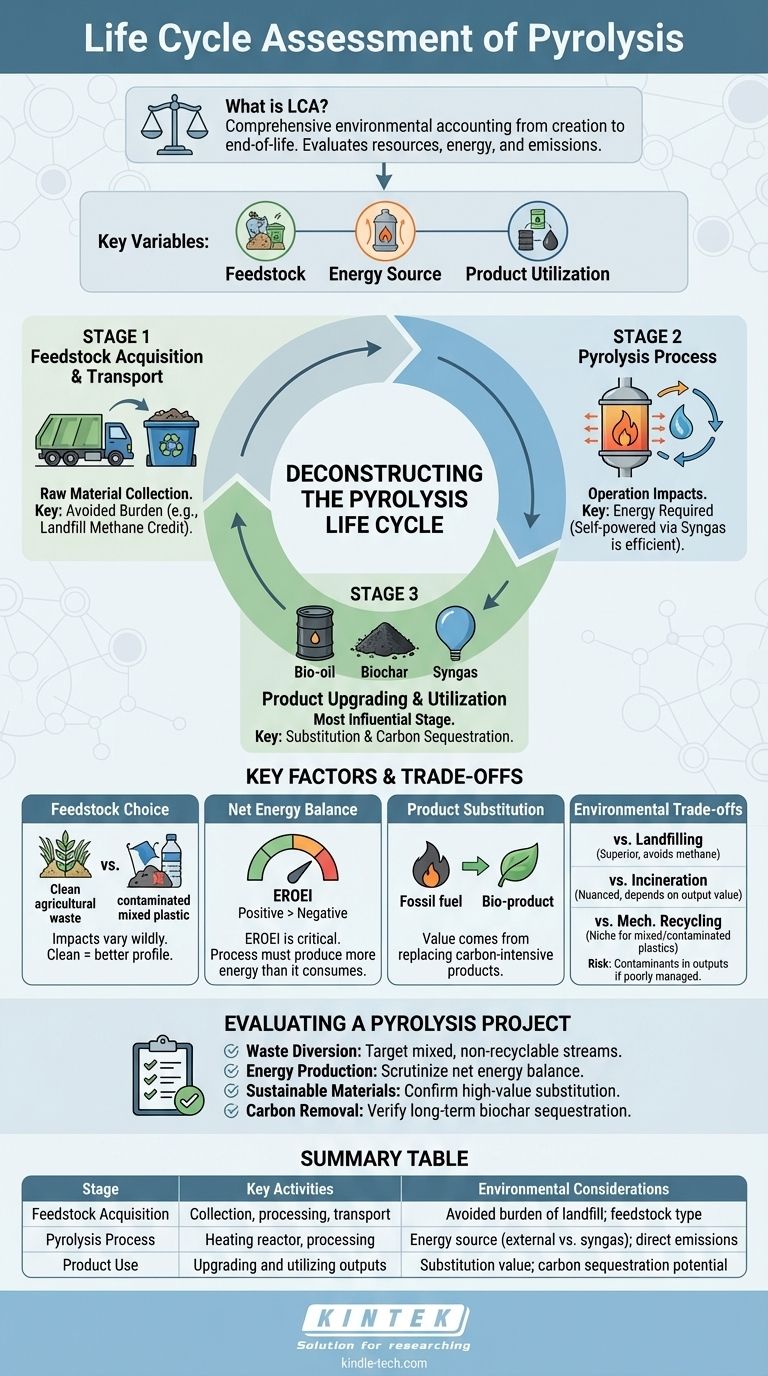

In short, a life cycle assessment (LCA) of pyrolysis is a comprehensive environmental accounting method used to quantify the total impact of a pyrolysis system from its creation to its end-of-life. It evaluates resource consumption, energy use, and emissions across all stages, including feedstock collection, the pyrolysis process itself, and the final use of its products (bio-oil, biochar, and syngas). The result is not a simple "good" or "bad" verdict, but a detailed profile of environmental performance across various categories like global warming potential, acidification, and water use.

The environmental performance of a pyrolysis system is not inherent to the technology itself. A pyrolysis LCA reveals that its true impact is almost entirely dependent on three critical variables: the feedstock being processed, the energy source for the reactor, and how the resulting products are utilized.

Deconstructing the Pyrolysis Life Cycle

A credible LCA divides the entire system into distinct stages to ensure all environmental inputs and outputs are accounted for. Understanding these stages is the first step in evaluating any specific pyrolysis project.

Stage 1: Feedstock Acquisition and Transport

The life cycle begins with the raw material. This includes the energy and emissions associated with collecting, processing, and transporting the feedstock (e.g., plastic waste, biomass, tires) to the pyrolysis facility.

A key concept here is the avoided burden. If the feedstock is a waste product, like mixed plastic destined for a landfill, the LCA can claim a credit for avoiding the environmental impacts of that landfill (such as methane emissions).

Stage 2: The Pyrolysis Process

This stage covers the direct impacts of the plant's operation. It quantifies the energy required to heat the reactor to operating temperature and accounts for any direct emissions from the process, such as fugitive gases or wastewater.

An efficient system will use the non-condensable syngas it produces as fuel to power the reactor, significantly reducing its reliance on external energy sources like natural gas or grid electricity and improving its environmental profile.

Stage 3: Product Upgrading and Utilization

This is often the most complex and influential stage. The environmental benefit of pyrolysis hinges on what is done with its outputs: bio-oil, biochar, and syngas.

If bio-oil replaces conventional fossil fuels, the LCA calculates an environmental credit based on the "substituted" fuel. Likewise, if biochar is used in agriculture to sequester carbon and improve soil, it generates a significant carbon removal credit. Conversely, if these products are used inefficiently or simply burned for low-grade heat, the benefits are diminished.

Key Factors That Determine the Outcome

The final LCA results can vary dramatically. An investor or policymaker must scrutinize the following factors to determine if a project is environmentally sound.

The Impact of Feedstock Choice

The material being pyrolyzed is paramount. Processing clean, homogeneous agricultural waste will have a vastly different LCA profile than processing contaminated, mixed municipal solid waste or shredded tires, which may contain heavy metals or sulfur that can end up in the outputs.

The Net Energy Balance

A critical metric is the Energy Return on Energy Invested (EROEI). A positive LCA result depends on the system producing significantly more energy than it consumes. A process that requires constant, high levels of external fossil fuel input is unlikely to be a net environmental positive.

The Value of Product Substitution

The concept of substitution is central. A pyrolysis system creates the most value when its outputs replace carbon-intensive products. For example, producing "circular" naphtha from waste plastic to make new plastics is a high-value substitution. Using biochar to permanently sequester carbon in soil is far more valuable than burning it as a low-grade fuel.

Understanding the Environmental Trade-offs

Pyrolysis is not a silver bullet. A proper assessment requires comparing it objectively to the alternatives.

Pyrolysis vs. Landfilling

For waste management, pyrolysis is almost always superior to landfilling. It prevents the anaerobic decomposition of organic waste, which releases potent methane gas, and it recovers value from the material instead of letting it become a long-term liability.

Pyrolysis vs. Incineration (Waste-to-Energy)

This comparison is more nuanced. Modern incineration plants are very efficient at generating electricity from waste. Pyrolysis can be environmentally preferable if it produces higher-value outputs like chemical feedstocks or stable biochar for carbon sequestration. If the bio-oil is simply burned for electricity, its efficiency may be lower than a state-of-the-art incinerator.

Pyrolysis vs. Mechanical Recycling

For clean, sorted plastic waste, mechanical recycling is typically the more energy-efficient and environmentally friendly option. Pyrolysis (often termed "advanced" or "chemical" recycling) finds its true niche in processing mixed, contaminated, or multi-layer plastics that cannot be mechanically recycled.

The Risk of Contaminants

A poorly designed or operated pyrolysis system, or one using contaminated feedstock, can mobilize hazardous substances. Heavy metals, sulfur, and other toxins can become concentrated in the bio-oil or biochar, creating a new environmental problem. A thorough LCA must account for the toxicity and safe disposal of all outputs.

How to Evaluate a Pyrolysis Project

Use the principles of LCA to ask the right questions and assess whether a project aligns with your primary goal.

- If your primary focus is waste diversion: Confirm the project is targeting waste streams that truly have no better destination, such as mixed plastics that are otherwise landfilled or incinerated.

- If your primary focus is energy production: Scrutinize the net energy balance and ensure the process is largely self-powered by its own syngas, comparing its carbon intensity to other energy sources.

- If your primary focus is producing sustainable materials: Investigate the quality of the outputs and confirm they are genuinely substituting for virgin materials in high-value applications, not just being burned.

- If your primary focus is carbon removal: The key is the long-term stability and application of the biochar; verify that it will be used for permanent sequestration in soil rather than combustion.

Ultimately, a credible life cycle assessment provides the necessary data to move beyond theoretical benefits and make a fact-based decision.

Summary Table:

| Stage | Key Activities | Key Environmental Considerations |

|---|---|---|

| Feedstock Acquisition | Collection, processing, transport of waste/biomass | Avoided burden of landfill; feedstock type (clean vs. contaminated) |

| Pyrolysis Process | Heating reactor, processing feedstock | Energy source (external vs. self-powered syngas); direct emissions |

| Product Use | Upgrading and utilizing bio-oil, biochar, syngas | Substitution value (replacing fossil fuels/chemicals); carbon sequestration potential |

Need precise, reliable lab equipment to analyze your pyrolysis process or products? KINTEK specializes in high-quality lab equipment and consumables for all your pyrolysis research and development needs. From feedstock analysis to product characterization, our solutions help you gather accurate data for a credible Life Cycle Assessment. Contact our experts today to find the right tools for your laboratory.

Visual Guide

Related Products

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Laboratory High Pressure Vacuum Tube Furnace

People Also Ask

- What is a tubular furnace used for? Precision Heating for Material Synthesis & Analysis

- How does a quartz tube vacuum furnace contribute to the crystallization process of Ag-doped Li-argyrodite electrolytes?

- How does a high-temperature tube furnace facilitate the phase transformation of alumina products? Master Thermal Control

- How do a quartz tube reactor and atmosphere furnace collaborate in Co@NC pyrolysis? Master Precision Synthesis

- Why is a quartz tube furnace utilized in the thermal oxidation of MnCr2O4 coatings? Unlock Precise Selective Oxidation