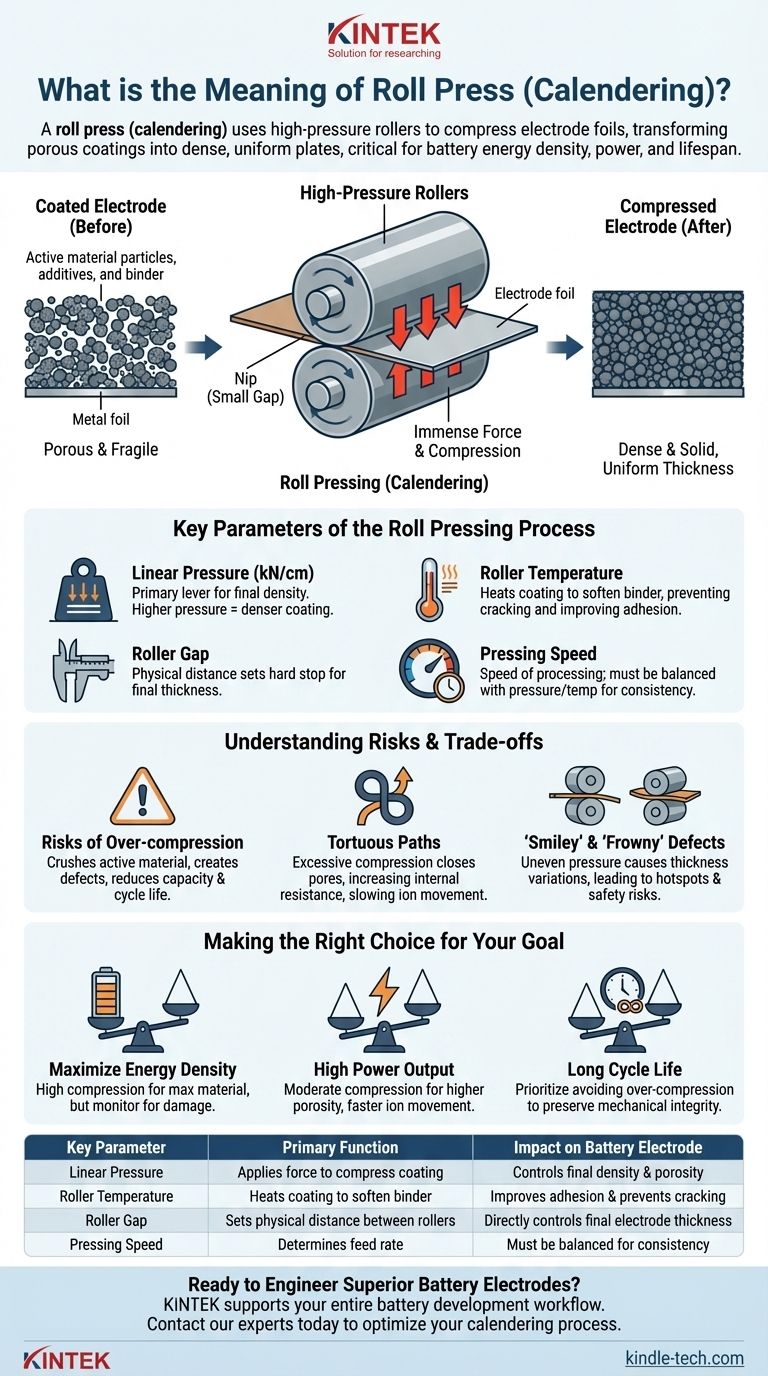

A roll press is a machine that uses high-pressure rollers to compress a material to a precise, uniform thickness and density. In the context of battery manufacturing, this process, also known as calendering, is a critical step applied to the electrode foils after the active material has been coated onto them. It transforms the porous, powdery coating into a dense, solid plate.

The central purpose of a roll press is not merely to flatten the electrode but to strategically engineer its microstructure. This single step directly dictates a battery's energy density, power capability, and overall lifespan by controlling the final thickness, porosity, and adhesion of the active material.

The Core Function: From Powder to Precision Plate

The roll pressing process is fundamental to achieving the performance targets of a modern lithium-ion battery. It takes a freshly coated electrode—which is fragile and has suboptimal electrical properties—and prepares it for assembly into a cell.

The Basic Mechanism

At its heart, a roll press consists of two large, perfectly smooth, and extremely heavy steel rollers. The coated electrode foil is carefully fed into the nip, which is the small gap between these two rollers. The immense force exerted by the rollers compresses the material as it passes through.

Why Compression is Critical

The electrode coating, whether it's graphite on copper foil (anode) or a cathode material like NMC on aluminum foil, is initially a mixture of active material particles, conductive additives, and a binder. This coating is porous and not very dense. Compression forces these particles into intimate contact with each other and with the current collector foil.

The Goal: Increasing Energy Density

The primary benefit of roll pressing is a significant increase in volumetric energy density. By compacting the active material, you can fit more of it into the same amount of space. This allows for a thinner electrode, meaning more layers can be stacked or wound into a battery can of a given size, resulting in a higher capacity cell.

Ensuring Uniformity and Adhesion

A second crucial goal is to achieve a perfectly uniform thickness across the entire width and length of the electrode roll. Even microscopic variations can create "hot spots" during charging and discharging, leading to premature degradation and safety risks. The pressure also improves the adhesion of the coating to the metal foil, preventing it from flaking off during subsequent manufacturing steps.

Key Parameters of the Roll Pressing Process

Optimizing the calendering process involves a careful balance of several interconnected variables. Each one must be precisely controlled to achieve the desired electrode characteristics.

Linear Pressure

This is the amount of force applied by the rollers, typically measured in kilonewtons per centimeter (kN/cm). It is the primary lever for controlling the final density of the electrode. Higher pressure results in a denser coating.

Roller Temperature

The rollers are often heated to a specific temperature. Heating softens the polymer binder (like PVDF) within the coating, making the material more pliable. This allows it to be compressed without cracking and improves its adhesion to the current collector foil.

Roller Gap

The physical distance set between the two rollers provides a hard stop, directly controlling the final thickness of the electrode. This is one of the most critical quality control parameters in all of battery manufacturing.

Pressing Speed

This is the speed at which the electrode foil is processed through the machine. The speed must be carefully matched with the pressure and temperature to ensure consistent results and avoid introducing defects.

Understanding the Trade-offs and Risks

While essential, roll pressing is a delicate balancing act. Pushing for one parameter, like maximum density, can negatively impact others, such as battery life or power performance.

The Risk of Over-compression

If the pressure is too high, it can physically crush the active material particles, particularly the structured graphite used in anodes. This mechanical damage creates defects that permanently reduce the battery's capacity and shorten its cycle life.

Creating Tortuous Paths

Excessive compression can also close off the microscopic pores within the electrode. These pores are vital as they must be filled with electrolyte to allow lithium ions to travel to the active material. Overly dense electrodes create a highly tortuous path for these ions, which dramatically increases internal resistance and cripples the battery's ability to charge or discharge quickly.

The "Smiley" and "Frowny" Defects

Maintaining perfectly even pressure across the entire width of a multi-foot-wide roller is a significant mechanical challenge. If the rollers bend even slightly under pressure, it can lead to the electrode being thicker at the edges than in the middle (a "frowny" profile) or vice versa (a "smiley" profile), ruining the uniformity required for a safe and reliable cell.

Making the Right Choice for Your Goal

The ideal roll press settings are determined entirely by the intended application of the battery cell.

- If your primary focus is maximizing energy density: You will target a high degree of compression to pack in as much active material as possible, but you must carefully monitor for signs of particle damage.

- If your primary focus is high power output: You will use more moderate compression to maintain a higher level of porosity, ensuring ions can move quickly and easily through the electrode.

- If your primary focus is long cycle life: You will prioritize avoiding over-compression, accepting a slightly lower initial density to preserve the mechanical integrity of the active materials for thousands of cycles.

Ultimately, mastering the roll press process is a foundational pillar of high-performance battery cell engineering, directly translating machine parameters into electrochemical results.

Summary Table:

| Key Roll Press Parameter | Primary Function | Impact on Battery Electrode |

|---|---|---|

| Linear Pressure | Applies force to compress the coating | Controls final density and porosity |

| Roller Temperature | Heats the coating to soften the binder | Improves adhesion and prevents cracking |

| Roller Gap | Sets the physical distance between rollers | Directly controls the final electrode thickness |

| Pressing Speed | Determines the feed rate of the electrode foil | Must be balanced with pressure/temp for consistency |

Ready to Engineer Superior Battery Electrodes?

Mastering the roll press process is fundamental to achieving your battery's performance targets for energy density, power, and cycle life. KINTEK specializes in providing the lab equipment and consumables you need for precise electrode R&D and quality control.

Our expertise supports your entire battery development workflow. Contact our experts today to discuss how we can help you optimize your calendering process and build better batteries.

Visual Guide

Related Products

- Laboratory Hydraulic Press Lab Pellet Press for Button Battery

- Single Punch Electric Tablet Press Machine Laboratory Powder Tablet Punching TDP Tablet Press

- Single Punch Tablet Press Machine and Mass Production Rotary Tablet Punching Machine for TDP

- Warm Isostatic Press for Solid State Battery Research

- Automatic Laboratory Heat Press Machine

People Also Ask

- What role does a laboratory hydraulic press play in the preparation of solid electrolyte pellets? Ensure Data Accuracy

- How is a hydraulic press helpful for making KBr pellets? Achieve Superior FTIR Sample Preparation

- Why is a laboratory hydraulic press essential for Ca3Co4O9 pelletizing? Optimize Pre-Sintering Mass Transport

- What is the use of manual hydraulic press? A Cost-Effective Tool for Lab Sample Preparation

- What is an example of a hydraulic press? Discover the Power of Laboratory Sample Preparation