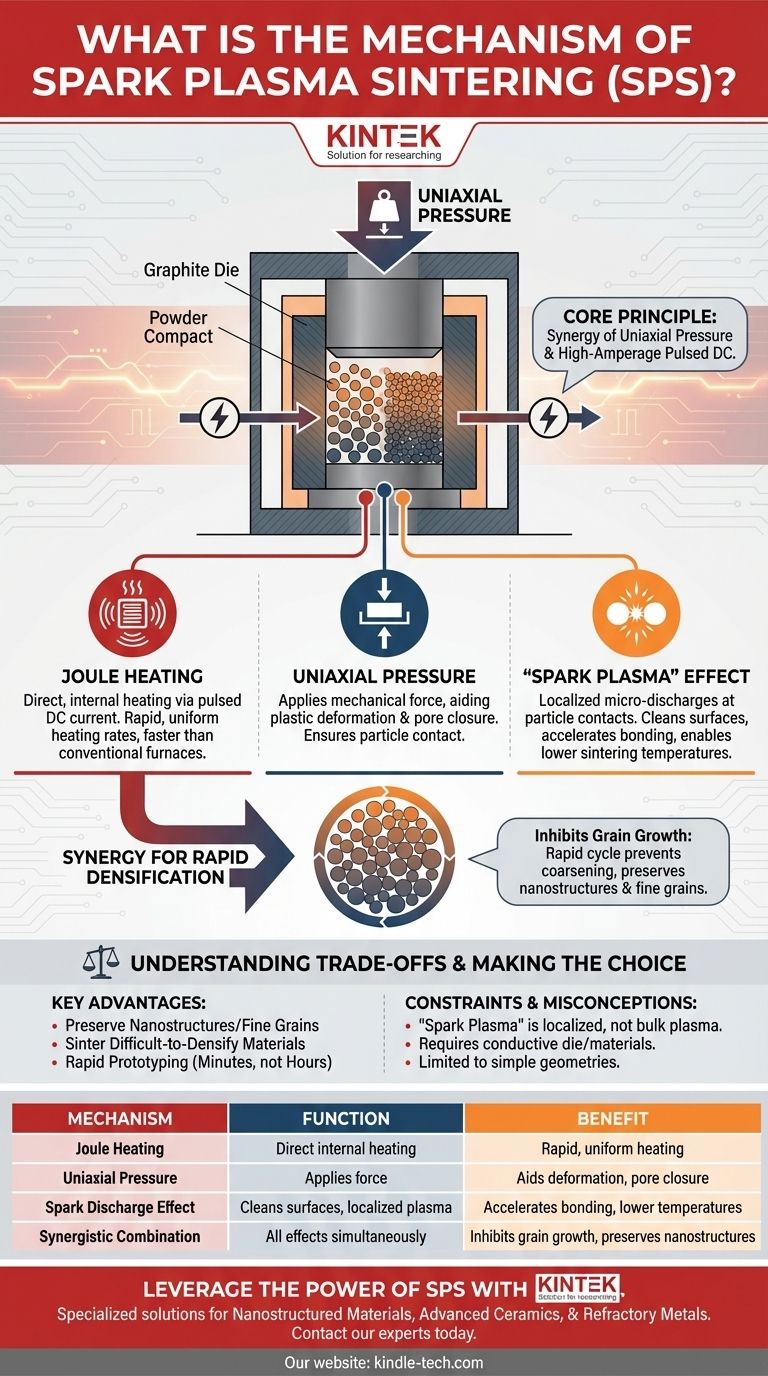

At its core, Spark Plasma Sintering (SPS) is an advanced sintering technique that uses a combination of uniaxial pressure and a high-amperage, pulsed direct current (DC) to rapidly consolidate powders into a dense solid. Unlike conventional furnaces that heat externally, SPS passes current directly through the sample and its conductive die, generating intense heat precisely where it is needed. This unique combination of factors accelerates densification dramatically.

The central mechanism of SPS is not just a single process, but a synergy of three effects: rapid Joule heating, mechanical pressure causing plastic deformation, and a debated but critical "spark plasma" effect that cleans and activates particle surfaces through localized electrical discharges. This combination enables faster sintering at lower temperatures, preserving unique material microstructures.

Deconstructing the SPS Mechanism

To truly understand SPS, we must break down the key phenomena that occur simultaneously during its very short process cycle.

Joule Heating: The Primary Driver

The foundational heating mechanism in SPS is Joule heating. As the high-amperage DC current passes through the conductive graphite die and, in many cases, the powder compact itself, electrical resistance generates intense, rapid, and uniform heat.

This is fundamentally different from a conventional furnace, which relies on slower radiation and convection to heat the sample from the outside in. The direct, internal heating in SPS is responsible for its exceptionally fast heating rates.

Uniaxial Pressure: Aiding Deformation

Simultaneously with the electrical current, a uniaxial force is applied to the die. This pressure serves a critical mechanical function.

It forces the powder particles into close contact, which is essential for both electrical conductivity and heat transfer. At elevated temperatures, this pressure also induces plastic deformation at the particle contact points, helping to close up pores and mechanically aid the densification process.

The "Spark Plasma" Effect: The Point of Debate

The most unique—and debated—aspect of SPS is the effect of the pulsed DC voltage at the microscopic level between individual powder particles.

While the name suggests a sustained plasma field, the consensus is that the process generates localized micro-discharges or sparks in the voids between particles. This momentary discharge is believed to create a pocket of high-temperature plasma.

This localized plasma has two profound effects. First, it helps strip away contaminants and oxide layers from the particle surfaces, creating clean, active sites. Second, it promotes rapid mass transport, accelerating the formation of "necks" that bond the particles together.

How These Factors Combine for Rapid Densification

The power of SPS comes from these three mechanisms working in perfect synergy, creating an environment that is exceptionally efficient at densification.

A Synergistic Process

Pressure creates the particle-to-particle contact points. Joule heating provides the necessary bulk thermal energy. The spark discharge effect delivers a final, highly localized burst of energy precisely at these contact points to overcome activation barriers and weld the particles together.

Inhibiting Grain Growth

A key advantage of this rapid, low-temperature process is the inhibition of grain growth. In conventional sintering, the long hold times at high temperatures allow grains to coarsen, which can degrade mechanical properties.

Because SPS completes the densification in minutes, the material becomes fully dense before the grains have time to grow significantly. This makes it an invaluable tool for producing nanostructured and fine-grained materials.

Understanding the Trade-offs and Misconceptions

While powerful, it's critical to approach SPS with a clear understanding of its nuances and limitations.

The Name Can Be Misleading

The term "Spark Plasma Sintering" is somewhat of a misnomer. Most researchers agree that a stable, bulk plasma is not generated. The key electrical phenomenon is more accurately described as localized electrical discharge between particle gaps, not a uniform plasma field.

Material and Geometry Constraints

SPS works most efficiently with electrically conductive or semi-conductive materials and requires a conductive die, which is almost always graphite. While techniques exist for sintering insulating materials, it is more complex. The process is also typically limited to producing simple geometries like discs and cylinders.

The Process is Not Fully Understood

As the research indicates, a completely unified and universally accepted model for the SPS mechanism does not yet exist. While the core principles are well-established, the precise interplay of electrical, thermal, and mechanical effects at the micro-level is still an area of active study.

Making the Right Choice for Your Goal

Understanding the SPS mechanism allows you to determine when it is the superior choice over conventional methods like hot pressing or furnace sintering.

- If your primary focus is preserving nanostructures or fine grains: SPS is the ideal choice, as its rapid cycle time prevents the grain growth that occurs during long-duration, high-temperature sintering.

- If your primary focus is sintering difficult-to-densify materials: The surface activation from the spark discharge effect makes SPS highly effective for consolidating advanced ceramics, composites, and refractory metals that resist conventional methods.

- If your primary focus is rapid materials discovery and prototyping: The entire SPS process takes minutes, not hours, making it an unparalleled tool for quickly developing and testing new material compositions.

Ultimately, understanding the SPS mechanism is about leveraging its unique combination of heat, pressure, and electrical energy to engineer advanced materials with properties that are simply out of reach for conventional methods.

Summary Table:

| Mechanism Component | Key Function | Resulting Benefit |

|---|---|---|

| Joule Heating | Direct, internal heating via pulsed DC current | Rapid, uniform heating; faster process cycles |

| Uniaxial Pressure | Applies force to powder compact | Aids plastic deformation and pore closure |

| Spark Discharge Effect | Cleans surfaces & creates localized plasma at particle contacts | Accelerates bonding; enables lower sintering temperatures |

| Synergistic Combination | All three effects work simultaneously | Inhibits grain growth; preserves nanostructures |

Ready to leverage the power of SPS in your lab?

KINTEK specializes in advanced lab equipment, including Spark Plasma Sintering systems. Our solutions are designed for researchers and engineers focused on developing nanostructured materials, advanced ceramics, and refractory metals.

By choosing KINTEK, you gain a partner dedicated to helping you achieve rapid densification while preserving critical material microstructures, accelerating your materials discovery and prototyping.

Contact our experts today to discuss how an SPS system can meet your specific research goals.

Visual Guide

Related Products

- Spark Plasma Sintering Furnace SPS Furnace

- Vacuum Heat Treat and Sintering Furnace with 9MPa Air Pressure

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

People Also Ask

- How do I choose a filter press? Match the Right Technology to Your Slurry for Optimal Results

- What is the pressure less sintering process? Achieve Uniform Density for Complex Parts

- What is the function of high-temperature thermal treatment equipment in TiO2/G nanocomposites? Optimize Photocatalysts

- What is the conventional sputtering method? A Guide to Controlled Thin-Film Deposition

- What is a reactive sputtering reaction? Synthesize Advanced Thin Films with Precision

- What is target poisoning in sputtering? A Guide to Process Instability and Control

- How to do sintering? Master the Process for High-Performance Ceramics & Metals

- What are the two important principles of heat treatment? Achieve Optimal Material Properties for Your Lab