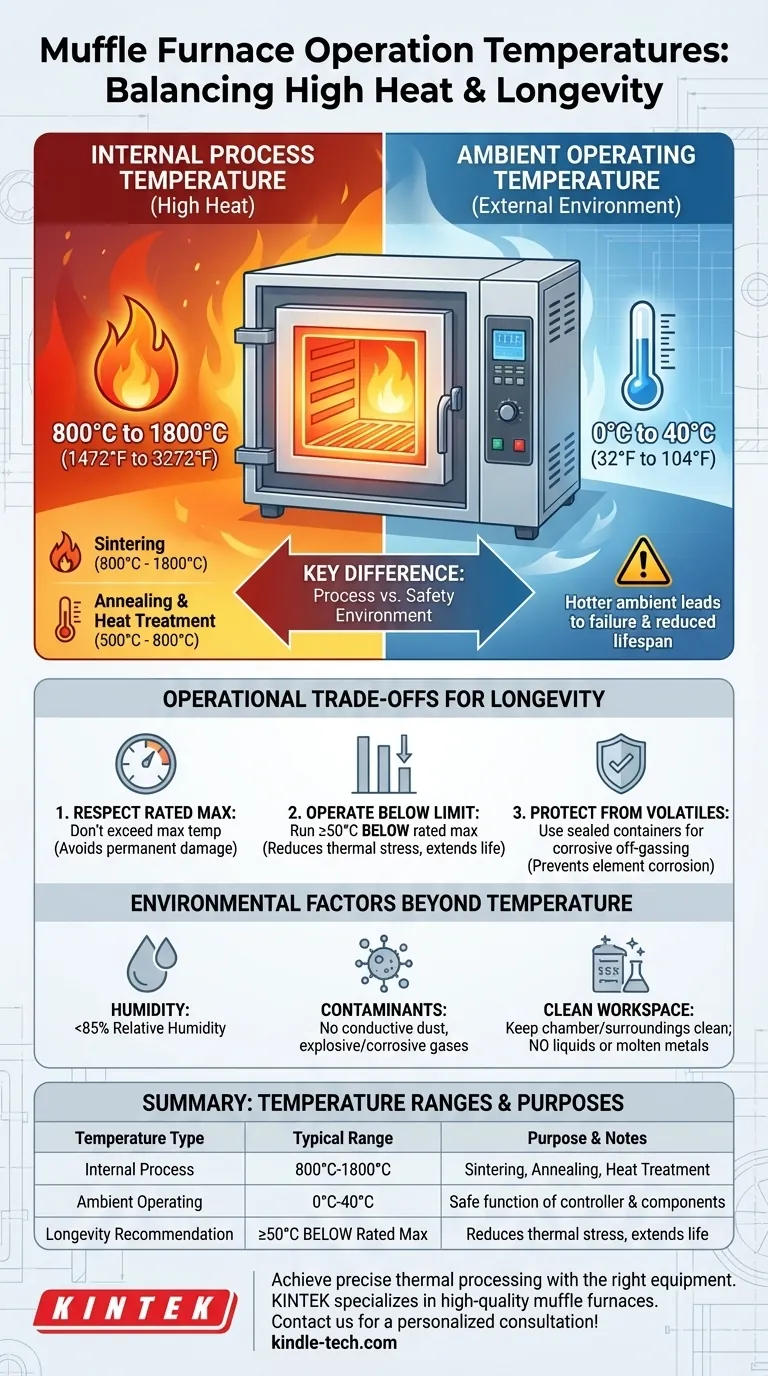

A muffle furnace's internal working temperature is exceptionally high, typically ranging from 800°C to 1800°C (1472°F to 3272°F). However, this is distinct from the ambient room temperature required for the equipment itself to function safely, which is much lower.

The most critical concept to understand is the difference between two separate temperature ranges: the extremely high internal temperature required for processing materials and the moderate ambient temperature required for the furnace's external components and controller to operate safely and reliably.

The Two Key Temperature Environments

A muffle furnace operates in two distinct thermal zones. Confusing them can lead to equipment damage or inaccurate results.

Internal Process Temperature

The internal chamber is where the work is performed, reaching temperatures that can fundamentally alter a material's physical or chemical properties.

Different processes require specific temperature ranges. For example, sintering applications typically utilize the higher end of the scale, from 800°C to 1800°C.

Processes like annealing and heat treatment are often performed at the lower end, generally between 500°C and 800°C.

Ambient Operating Temperature

The furnace's sophisticated electronic controller and external body are not designed for high heat. They must be kept in a controlled environment to function correctly.

The ideal ambient temperature range for the furnace controller and its surroundings is between 0°C and 40°C (32°F and 104°F).

Operating the equipment in a room hotter than this can lead to electronic failure, inaccurate temperature readings, and a shortened lifespan.

Understanding the Operational Trade-offs

Proper temperature management is not just about reaching a setpoint; it's about balancing performance with the longevity and safety of the equipment.

Respect the Rated Maximum

Never operate the furnace above its rated maximum temperature. Doing so can permanently damage or destroy the electric heating elements.

Operate Below the Limit for Longevity

For extending the life of the furnace's heating elements, a crucial best practice is to operate it at least 50°C below its rated maximum.

This small buffer significantly reduces thermal stress on the components, leading to more reliable operation and lower maintenance costs over time.

Protect Elements from Volatile Materials

When heating materials that release volatile gases, such as metals or certain polymers, these gases can corrode the heating elements.

To prevent this, samples should be placed in sealed containers or the furnace should be properly ventilated to safely exhaust the corrosive off-gassing.

Environmental Factors Beyond Temperature

The room where the muffle furnace operates is as important as the temperature settings.

Humidity and Contaminants

The relative humidity of the operating environment should not exceed 85%.

The area must be free of conductive dust, explosive gases, or corrosive gases, all of which can damage the furnace's electronics and create safety hazards.

Maintaining a Clean Workspace

Keeping the furnace chamber and its surroundings clean is essential. Foreign materials like dust or fibers can compromise the process and present a fire risk at high temperatures.

Never pour liquids or molten metals directly into the furnace chamber.

Making the Right Choice for Your Goal

Use these guidelines to match your operating parameters to your objective.

- If your primary focus is high-temperature sintering: Select a furnace rated for the 800°C to 1800°C range and ensure your specific target is well within its capabilities.

- If your primary focus is annealing or general heat treatment: A furnace capable of reaching 500°C to 800°C will be sufficient and often more cost-effective.

- If your primary focus is equipment longevity and safety: Always operate in a climate-controlled room (0-40°C) and consistently run cycles at least 50°C below the furnace's rated maximum temperature.

Understanding these operational principles is the key to achieving consistent, reliable results with your muffle furnace.

Summary Table:

| Temperature Type | Typical Range | Purpose & Notes |

|---|---|---|

| Internal Process Temperature | 800°C to 1800°C (1472°F to 3272°F) | For sintering, annealing, and heat treatment of materials. |

| Ambient Operating Temperature | 0°C to 40°C (32°F to 104°F) | For safe and reliable function of the furnace's controller and external components. |

| Recommended for Longevity | Operate at least 50°C below the furnace's rated maximum | Reduces thermal stress on heating elements and extends equipment life. |

Achieve precise and reliable thermal processing with the right equipment. Understanding the correct operating temperatures is crucial for your lab's success and safety. KINTEK specializes in high-quality lab equipment, including muffle furnaces designed for optimal performance across a wide range of applications. Our experts can help you select the perfect furnace for your specific temperature needs, whether for high-temperature sintering or precise heat treatment.

Ensure your lab operates efficiently and safely—contact our team today for a personalized consultation!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1400℃ Muffle Oven Furnace for Laboratory

- 1800℃ Muffle Oven Furnace for Laboratory

- 1700℃ Muffle Oven Furnace for Laboratory

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- What is the meaning of muffle furnace? The Key to Pure, High-Temperature Processing

- What precautions should be taken while heating and cooling the crucible? Prevent Thermal Shock and Ensure Safety

- How does heat affect strength materials? The Science of Thermal Degradation Explained

- What is the temperature verification of muffle furnace? Ensure Accurate Thermal Processing

- What type of furnace is a muffle furnace? A Guide to High-Purity, Contamination-Free Heating