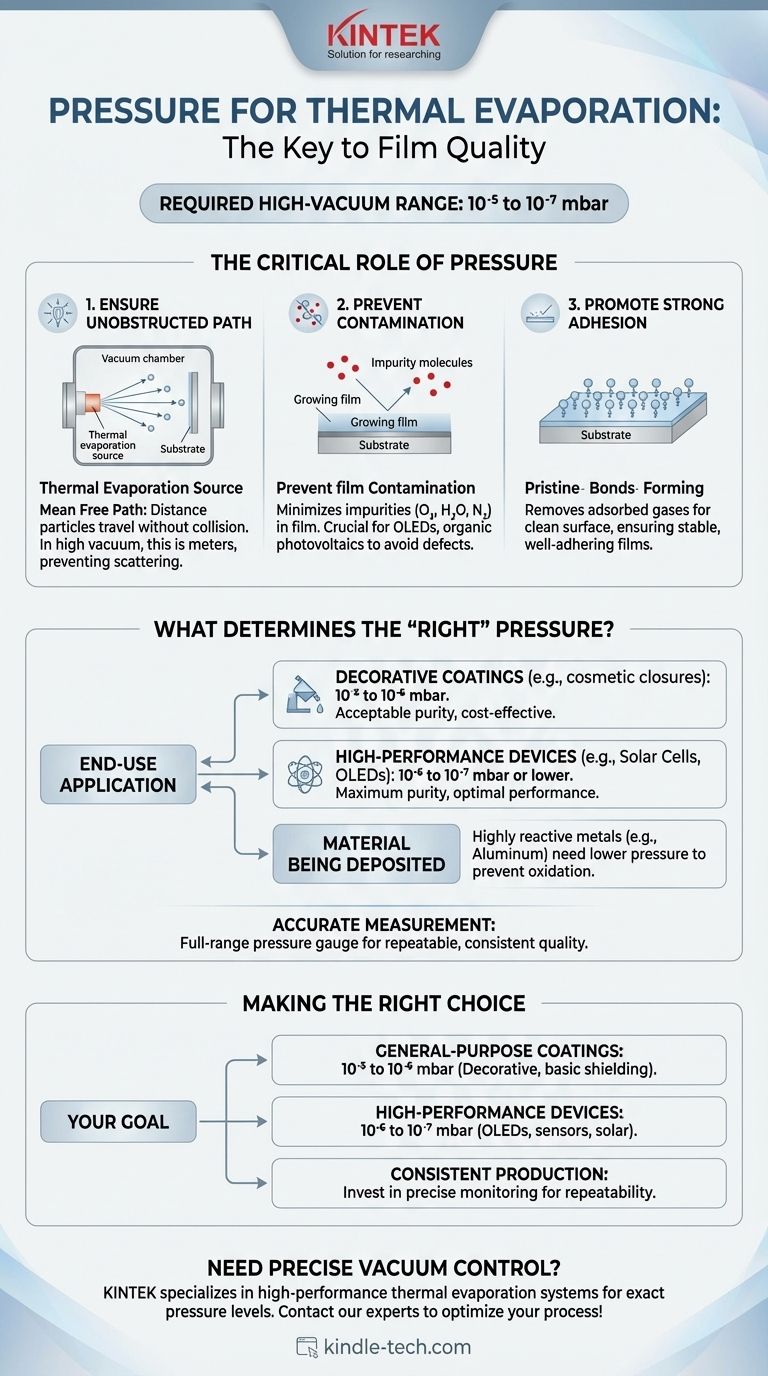

The required base pressure for thermal evaporation is typically in the high-vacuum range, between 10⁻⁵ and 10⁻⁷ millibar (mbar). The specific pressure you need within this range is dictated entirely by the required purity and performance of the final thin film. For less demanding applications, a higher pressure may suffice, but for high-performance electronics, a lower base pressure is non-negotiable.

The core principle is that achieving a high vacuum isn't just a procedural step; it's a fundamental requirement for quality. Low pressure ensures that evaporated material can travel directly to a clean substrate without colliding with or being contaminated by residual air molecules.

The Critical Role of Pressure in Film Quality

Achieving the correct vacuum level directly impacts the structural integrity, purity, and adhesion of the deposited layer. This is not about simply removing air, but about creating a controlled environment where atoms can behave predictably.

Ensuring an Unobstructed Path

The primary goal of the vacuum is to increase the mean free path of the evaporated atoms. This is the average distance a particle can travel before colliding with another particle.

In a high-vacuum environment (e.g., 10⁻⁶ mbar), the mean free path is several meters long. This is much greater than the typical distance between the evaporation source and the substrate, ensuring atoms travel in a straight line and arrive without being scattered by residual gas molecules.

Preventing Film Contamination

Any molecules remaining in the chamber—like oxygen, water vapor, or nitrogen—can become incorporated into the growing film as impurities. This contamination can be catastrophic for sensitive applications.

In devices like OLEDs or organic photovoltaics, these impurities can create defects that degrade electrical performance, reduce efficiency, and drastically shorten the device's lifespan. A lower base pressure minimizes the presence of these contaminants.

Promoting Strong Adhesion

A high vacuum is also essential for preparing a pristine substrate surface. The vacuum helps remove adsorbed gases and contaminants from the substrate before deposition begins.

This provides a clean surface that allows the evaporated atoms to bond directly and strongly, forming a stable and well-adhering film. Poor adhesion can lead to delamination and device failure.

What Determines the "Right" Pressure?

The ideal base pressure is not a single number but a target based on your specific process and quality requirements.

The End-Use Application

The required quality of the final layer is the most significant factor.

Decorative applications, such as metallized cosmetic closures or sporting goods, may tolerate a higher base pressure in the 10⁻⁵ mbar range. In contrast, high-performance thin-film devices like solar cells, OLEDs, or medical reflectors demand much lower pressures (10⁻⁶ to 10⁻⁷ mbar or better) to achieve the necessary purity.

The Material Being Deposited

Highly reactive metals are more susceptible to contamination from residual gases. When depositing materials that readily oxidize, such as aluminum, achieving a lower base pressure is critical to prevent the formation of unwanted oxide layers within the film.

The Importance of Accurate Measurement

You cannot control what you cannot measure. A reliable, full-range pressure gauge is crucial for monitoring the deposition environment from atmospheric pressure down to the high-vacuum range.

This ensures not only that you reach the target base pressure but also that the process is repeatable, which is essential for consistent quality in both research and production settings.

Understanding the Trade-offs

While effective, thermal evaporation has inherent limitations that are important to acknowledge.

Simplicity vs. Purity

Thermal evaporation is valued for its simplicity and robustness. However, because it heats the entire crucible, there is a risk of contamination from the crucible material itself becoming incorporated into the film.

Material Limitations

The technique is excellent for depositing materials with relatively low melting points, such as aluminum, silver, and gold. It is not suitable for refractory metals or materials that require very high temperatures to evaporate, as this would overwhelm the source and crucible.

Making the Right Choice for Your Goal

Selecting the correct pressure target is a function of balancing cost, time, and the required quality of the final product.

- If your primary focus is general-purpose coatings (e.g., decorative layers, basic EMI shielding): A moderate vacuum in the 10⁻⁵ to 10⁻⁶ mbar range is often a sufficient and cost-effective target.

- If your primary focus is high-performance devices (e.g., OLEDs, sensors, solar cells): A high to ultra-high vacuum (10⁻⁶ to 10⁻⁷ mbar or lower) is essential to minimize contamination and maximize performance.

- If your primary focus is consistent, repeatable production: Prioritize investing in precise pressure monitoring and control systems to ensure every deposition cycle meets the exact same environmental standards.

Ultimately, controlling the pressure is about controlling the purity and structure of your material at the atomic level.

Summary Table:

| Application Type | Typical Base Pressure Range | Key Goal |

|---|---|---|

| Decorative Coatings / Basic Shielding | 10⁻⁵ to 10⁻⁶ mbar | Cost-effective, acceptable purity |

| High-Performance Devices (OLEDs, Solar Cells) | 10⁻⁶ to 10⁻⁷ mbar or lower | Maximum purity, optimal performance |

Need precise vacuum control for your thin-film deposition? KINTEK specializes in high-performance lab equipment, including thermal evaporation systems designed to achieve the exact pressure levels your application demands. Whether you're developing OLEDs, sensors, or decorative coatings, our solutions ensure repeatable, high-purity results. Contact our experts today to discuss how we can optimize your process!

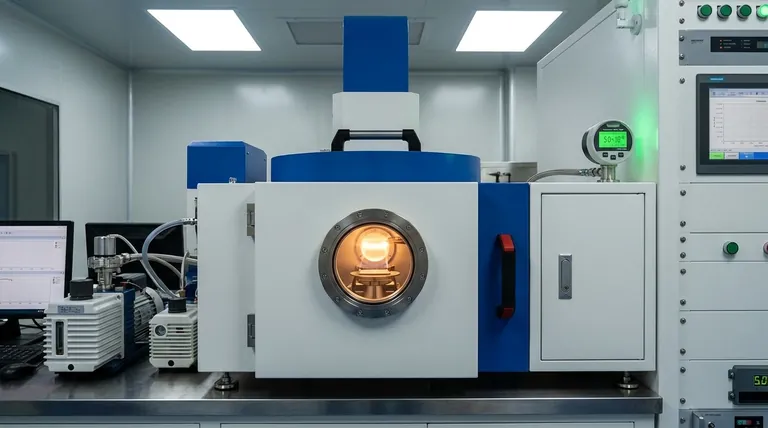

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Evaporation Boat for Organic Matter

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Hemispherical Bottom Tungsten Molybdenum Evaporation Boat

- Electron Beam Evaporation Coating Conductive Boron Nitride Crucible BN Crucible

People Also Ask

- Can gold turn into vapor? Unlocking the Extreme Science Behind Gold's Stability

- Where is physical Vapour deposition used? Enhancing Surfaces for Aerospace, Electronics & More

- Why is vacuum needed in thermal evaporation? For Pure, Uniform Thin Films

- What is sputtering or thermal evaporation? Choose the Right Thin-Film Deposition Method

- What are the uses of evaporation in industry? From Food Concentration to High-Tech Thin Films

- What temperature does evaporation occur? Unlock the Secrets to Controlling the Rate of Evaporation

- What are the effects of temperature and pressure on evaporation? Mastering Control for Your Process

- What is the vacuum evaporation technique for thin films? A Guide to High-Purity Thin Film Deposition