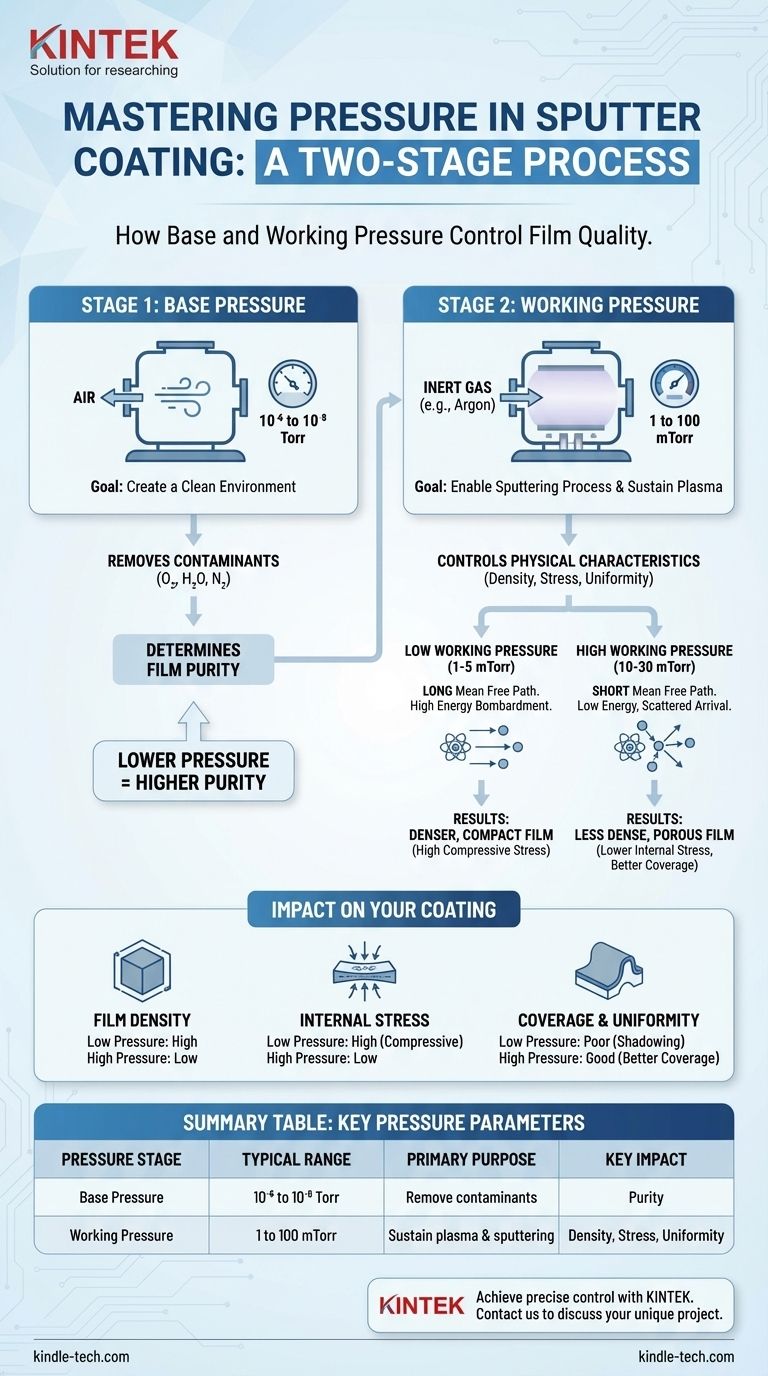

In sputter coating, pressure is not a single value but a two-stage process. The system first achieves a high vacuum known as the base pressure to ensure purity. Then, an inert gas is introduced to reach a higher working pressure (or process pressure) to create the plasma and initiate the sputtering of the target material.

The initial base pressure determines the purity of the coating, while the subsequent working pressure controls the physical characteristics of the deposited film, such as its density, stress, and uniformity.

The Two Critical Pressure Regimes in Sputtering

Understanding the distinction between base and working pressure is fundamental to controlling the outcome of any sputtering process. Each serves a distinct and critical purpose.

Base Pressure: Creating a Clean Environment

The base pressure is the level of vacuum achieved in the chamber before the sputtering gas is introduced.

Its sole purpose is to remove atmospheric and other contaminant molecules, such as oxygen, water vapor, and nitrogen. These particles can react with the sputtered material and become incorporated into the film as impurities.

A lower base pressure results in a purer, higher-quality film. For many applications, a base pressure in the range of 10⁻⁶ to 10⁻⁸ Torr is required.

Working Pressure: Enabling the Sputtering Process

Once a sufficient base pressure is reached, an inert gas (typically Argon) is bled into the chamber to raise the pressure to the working pressure.

This pressure, typically between 1 and 100 millitorr (mTorr), is necessary to sustain the plasma that bombards the target material, ejecting the atoms that will form the coating. The choice of working pressure is a critical process parameter.

How Working Pressure Directly Impacts Your Coating

The working pressure directly influences how sputtered atoms travel from the target to your sample, which in turn dictates the final properties of the film.

The Mean Free Path of Sputtered Atoms

The key physical principle at play is the mean free path (MFP)—the average distance a particle travels before colliding with another.

At lower working pressures (e.g., 1-5 mTorr), the chamber has fewer gas atoms. Sputtered particles have a long MFP, allowing them to travel directly to the substrate with high kinetic energy.

At higher working pressures (e.g., 10-30 mTorr), the chamber is denser with gas atoms. Sputtered particles have a short MFP, causing them to undergo many collisions, lose energy, and arrive at the substrate from multiple angles.

Impact on Film Density and Stress

The energy of the arriving particles has a profound effect on the film's microstructure.

A low-pressure process results in high-energy particle bombardment, creating a denser, more compact film. This high energy, however, can also induce higher compressive stress, which may cause the film to peel or crack.

A high-pressure process leads to low-energy particle deposition. This produces a less dense, more porous film that typically exhibits lower internal stress.

Impact on Deposition Rate

The relationship between pressure and deposition rate is not linear. Too little pressure means there are not enough gas ions to sputter the target effectively.

Conversely, excessively high pressure causes sputtered atoms to be scattered so much that many never reach the substrate, which also reduces the effective deposition rate. There is an optimal pressure range for maximizing the rate for any given system.

Understanding the Trade-offs

Selecting the right pressure involves balancing competing objectives. There is no single "best" pressure; the optimal value depends entirely on the desired outcome.

Purity vs. Process Time

Achieving an ultra-high vacuum for a very low base pressure ensures maximum film purity. However, this can require significant pumping time, reducing throughput. You must balance the required purity against practical process schedules.

Film Density vs. Stress

A dense film created at low pressure is excellent for barrier applications. But if the resulting compressive stress is too high for the substrate, the film will fail. Sometimes, a slightly less dense but more stable film created at higher pressure is the better choice.

Coverage vs. Film Properties

For coating complex, non-flat surfaces, the increased scattering at higher pressures can improve the uniformity and coverage in shadowed areas. This benefit comes at the cost of lower film density and a slower deposition rate.

Setting Your Pressure for Optimal Results

To apply this knowledge, consider your primary goal for the coating.

- If your primary focus is a dense, high-purity barrier film: Aim for the lowest possible base pressure your system can achieve and a low working pressure (typically 1-5 mTorr).

- If your primary focus is minimizing film stress or coating a complex shape: Consider a higher working pressure (e.g., 10-20 mTorr) to reduce particle energy and increase scattering.

- If your primary focus is maximizing deposition rate: You must experimentally find the optimal pressure point where sputtering efficiency is high but scattering losses are still minimal.

Mastering pressure control is the key to transforming sputter coating from a simple process into a precise engineering tool.

Summary Table:

| Pressure Stage | Typical Range | Primary Purpose | Key Impact on Coating |

|---|---|---|---|

| Base Pressure | 10⁻⁶ to 10⁻⁸ Torr | Remove contaminants for a clean environment | Determines the purity of the deposited film |

| Working Pressure | 1 to 100 mTorr | Sustain plasma and enable the sputtering process | Controls density, stress, uniformity, and deposition rate |

Ready to achieve precise control over your thin-film coatings?

The right sputter coater is key to mastering pressure parameters for your specific application—whether you need a dense barrier film, minimal stress, or excellent coverage on complex geometries. KINTEK specializes in high-quality lab equipment, including sputter coaters designed for reliable performance and precise process control.

Let our experts help you select the ideal system to meet your laboratory's unique needs. Contact us today to discuss your project and discover the KINTEK difference!

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Vacuum Heat Treat and Sintering Furnace with 9MPa Air Pressure

- VHP Sterilization Equipment Hydrogen Peroxide H2O2 Space Sterilizer

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

People Also Ask

- What is plasma activated chemical vapor deposition? Enable Low-Temperature Thin Film Deposition

- What is plasma CVD? Unlock Low-Temperature Thin Film Deposition for Sensitive Materials

- What is plasma enhanced? A Guide to Low-Temperature, High-Precision Manufacturing

- What is plasma activated chemical vapour deposition method? A Low-Temperature Solution for Advanced Coatings

- How does RF power create plasma? Achieve Stable, High-Density Plasma for Your Applications