At its core, a dental press furnace is a highly specialized oven that uses a combination of precise heat and pneumatic pressure to fabricate strong, aesthetic, and perfectly-fitting ceramic dental restorations. Its primary function is to transform a pre-made ceramic ingot into a final restoration, such as a crown, inlay, onlay, or bridge, by pressing the heat-softened material into a custom mold.

The press furnace is the critical link between a wax design and a final high-strength ceramic restoration. It enables the "lost-wax" technique for modern dental ceramics, ensuring unparalleled precision, density, and fit in the final product.

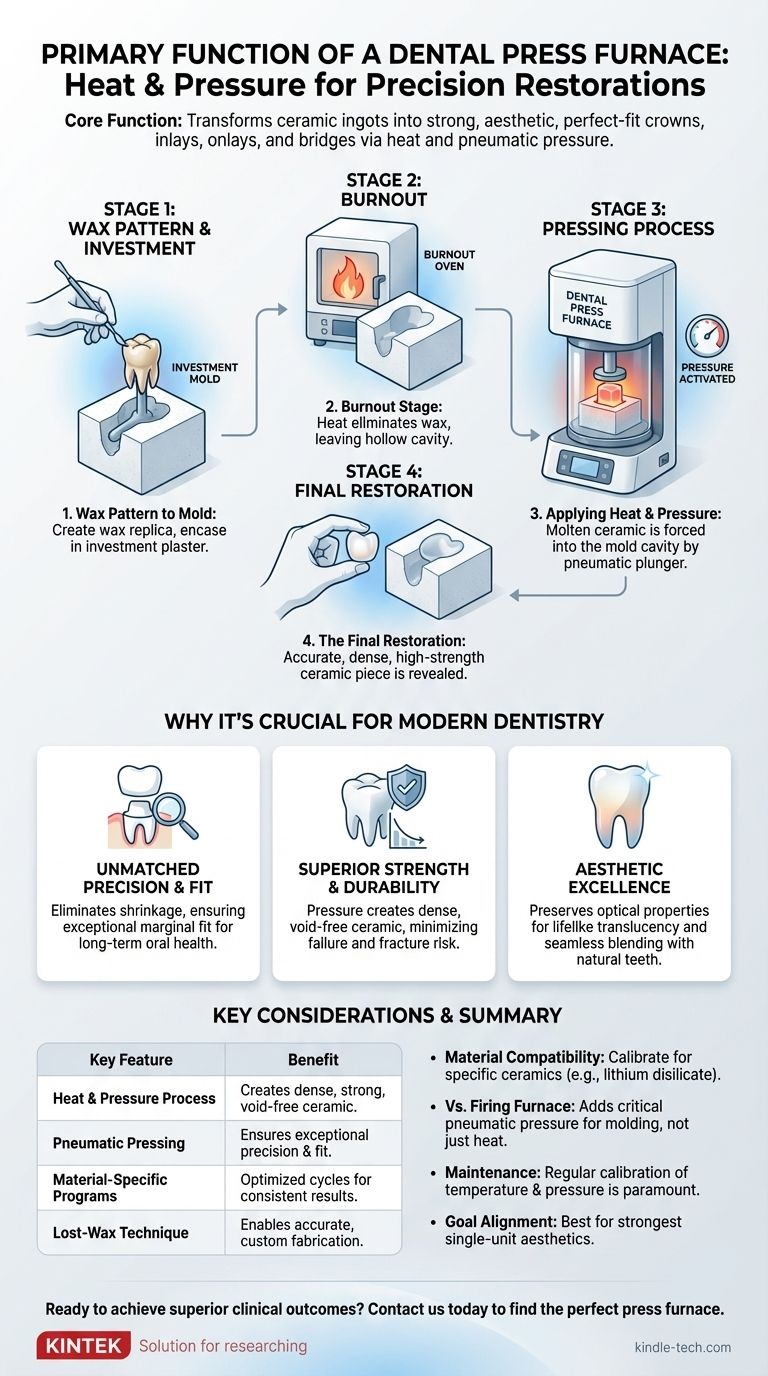

The Pressing Process: A Step-by-Step Breakdown

To understand the furnace's function, you must first understand the workflow it enables. The process is a modern evolution of the classic "lost-wax" casting technique used for centuries in jewelry and metalwork.

From Wax Pattern to Investment Mold

First, a dental technician creates a perfect replica of the desired restoration using a special type of wax. This is known as the wax pattern.

This wax pattern is then attached to a sprue (a small wax channel) and encased in a heat-resistant plaster-like material called investment. Once the investment hardens, it forms a precise mold around the wax.

The Burnout Stage

The investment mold is placed into a separate burnout oven (or a pre-heating cycle in the press furnace). The heat melts and completely eliminates the wax, leaving behind a hollow, negative space that is an exact mirror image of the original restoration design.

The Role of the Press Furnace

This is the critical stage. A ceramic ingot of a specific shade and translucency is selected and placed into the mold, along with a ceramic plunger.

The entire assembly is then placed into the dental press furnace. The furnace executes a pre-programmed cycle, carefully raising the temperature until the ceramic ingot reaches a molten, plastic-like state.

Applying Precise Pressure

Once the ceramic is at the optimal temperature, the furnace activates a pneumatic press, driving the plunger down. This action forces the molten ceramic into the hollow cavity of the mold, ensuring it fills every microscopic detail of the intended design.

The Final Restoration

After the cycle is complete and the mold has cooled, the investment material is carefully broken away. This reveals a dense, incredibly accurate ceramic restoration that is now ready for final staining, glazing, and polishing.

Why This Method is Crucial for Modern Dentistry

The press furnace isn't just a piece of heating equipment; it's a tool for achieving superior clinical outcomes. The combination of heat and pressure delivers distinct advantages over other fabrication methods.

Unmatched Precision and Fit

By actively pressing the material into the mold, the furnace eliminates the minor shrinkage and inaccuracies that can occur with simple firing or layering techniques. This results in restorations with an exceptional marginal fit, which is critical for long-term oral health.

Superior Strength and Durability

The pressure applied during the cycle creates a highly dense, void-free ceramic structure. This minimizes internal porosity, which is a common point of failure, making pressed ceramics significantly stronger and more fracture-resistant than many other materials.

Aesthetic Excellence

Pressable ceramic systems are available in a vast range of shades and opacities. The pressing process preserves these optical properties, allowing for the creation of restorations that blend seamlessly with natural teeth and exhibit lifelike translucency.

Understanding the Key Considerations

While powerful, a press furnace is a specific tool for a specific job. Success depends on understanding its operational principles and limitations.

Material Compatibility is Non-Negotiable

A press furnace must be properly calibrated for the specific ceramic material system you are using (e.g., lithium disilicate or leucite-reinforced glass). Each material has a unique set of parameters for temperature, heating rate, and pressure. Using incorrect settings will lead to a failed restoration.

The Difference Between Firing and Pressing

It's important to distinguish a press furnace from a standard porcelain or firing furnace. A firing furnace only uses heat to sinter, glaze, or cure dental materials. A press furnace does everything a firing furnace can do, but adds the critical component of pneumatic pressure for molding.

Maintenance and Calibration

The accuracy of the temperature and pressure systems is paramount. Regular calibration according to the manufacturer's guidelines is essential to ensure consistent, high-quality results and prevent costly failures.

Making the Right Choice for Your Goal

- If your primary focus is fabricating the strongest and most aesthetic single-unit restorations (crowns, veneers, inlays): A dental press furnace is the industry's gold standard for its reliability and the superior physical properties of the final product.

- If your primary focus is on producing multi-unit bridges or substructures: While some pressable materials work, this area is often dominated by CAD/CAM milling of materials like zirconia, although pressing can be used to veneer those frameworks.

- If your primary focus is a fully digital workflow with maximum speed: A chairside or lab-based CAD/CAM milling system may be a more direct solution, but it produces restorations with different physical properties than pressed ceramics.

Ultimately, the dental press furnace is a cornerstone technology that empowers dental professionals to create restorations of the highest quality and durability.

Summary Table:

| Key Feature | Benefit |

|---|---|

| Heat & Pressure Process | Creates dense, void-free ceramic restorations for superior strength. |

| Pneumatic Pressing | Ensures exceptional precision and marginal fit, critical for oral health. |

| Material-Specific Programs | Optimized cycles for materials like lithium disilicate for consistent results. |

| Lost-Wax Technique | Enables the fabrication of highly accurate, custom dental prosthetics. |

Ready to achieve superior clinical outcomes with precision-crafted dental restorations?

A dental press furnace is the cornerstone of a high-quality dental lab, enabling you to fabricate strong, aesthetic, and perfectly-fitting crowns, inlays, and onlays. KINTEK specializes in providing reliable lab equipment, including dental press furnaces, to meet the exacting demands of dental professionals.

Contact us today to find the perfect press furnace for your lab and elevate the quality of your ceramic restorations.

Visual Guide

Related Products

- Dental Porcelain Zirconia Sintering Ceramic Furnace Chairside with Transformer

- Vacuum Dental Porcelain Sintering Furnace

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Laboratory High Pressure Vacuum Tube Furnace

People Also Ask

- What is a dental oven? The Precision Furnace for Creating Strong, Aesthetic Dental Restorations

- What is the effect of zirconia sintering temperature? Master the Key to Strength and Stability

- What is one of the newest applications for dental ceramics? Monolithic Zirconia for Full-Arch Bridges

- What is the sintering temperature of zirconium? A Guide to the 1400°C-1600°C Range for Dental Labs

- What is the price of zirconia sintering furnace? Invest in Precision, Not Just a Price Tag