In the context of laboratory work, the primary purpose of freeze drying, or lyophilization, is to preserve a sample by removing water without damaging its delicate internal structure. This process extends the shelf life of perishable materials and makes them more stable for long-term storage or transport, ensuring their biological and chemical integrity remains intact for future analysis.

Freeze drying is not merely about dehydration; it's a precise preservation technique. By converting frozen water directly into gas—a process called sublimation—it bypasses the destructive liquid phase, safeguarding the original characteristics of sensitive materials like proteins, microbes, and tissues.

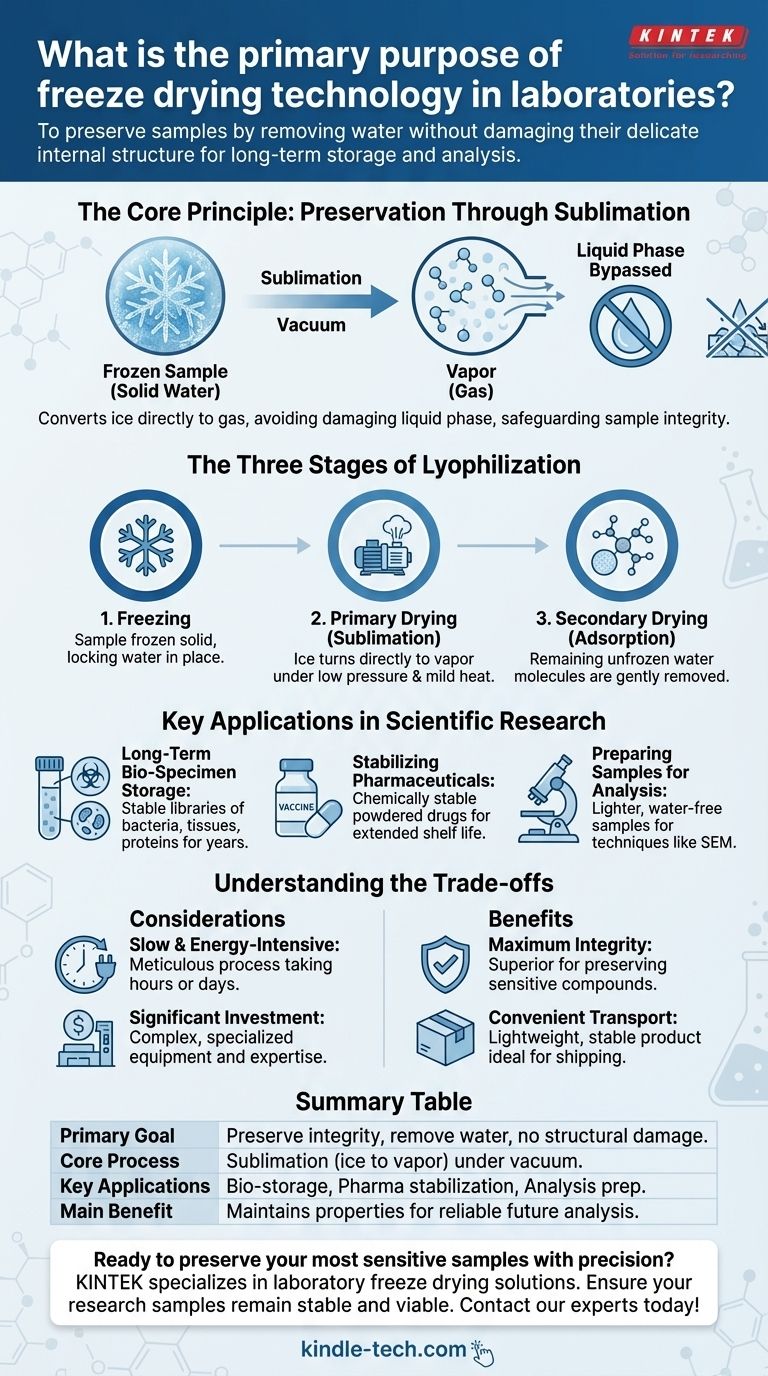

The Core Principle: Preservation Through Sublimation

The unique value of freeze drying lies in how it removes water. Unlike simple heating or evaporation, which can shrink or destroy a sample's structure, freeze drying is a far gentler process.

Why Bypassing the Liquid Phase is Critical

As water transitions from solid ice to liquid, it can form crystals that damage cell walls. The surface tension of evaporating liquid water can also cause a sample's structure to collapse.

Sublimation—turning ice directly into vapor under a vacuum—avoids these issues entirely. This preserves the sample's physical form, from its macroscopic shape down to its microscopic cellular structure.

The Three Stages of Lyophilization

The process is methodical and consists of three main phases:

- Freezing: The material is frozen solid, locking water molecules in place and protecting the sample's structure.

- Primary Drying (Sublimation): The pressure is lowered in a vacuum chamber, and a small amount of heat is added, causing the frozen water to turn directly into vapor, which is then collected.

- Secondary Drying (Adsorption): After the ice is gone, any remaining unfrozen water molecules are gently removed to achieve the final, stable, and preserved state.

Key Applications in Scientific Research

By maintaining the structural integrity of samples, freeze drying becomes essential for ensuring the reliability and reproducibility of scientific work.

Long-Term Bio-Specimen Storage

Freeze drying is the gold standard for preserving biological samples like bacteria, viruses, tissues, and proteins. This allows for the creation of stable sample libraries that can be used for years.

This is particularly crucial for longitudinal studies, where researchers must compare samples collected at different times without any degradation affecting the results.

Stabilizing Pharmaceuticals

Many modern drugs, especially biologics and vaccines, are unstable in a liquid solution and would quickly lose their effectiveness.

Freeze drying removes the water, rendering the pharmaceutical product chemically stable in a powdered or "caked" form. It can then be stored for extended periods and reconstituted with a sterile liquid just before use.

Preparing Samples for Analysis

Removing water makes a sample significantly lighter and easier to transport. It also prepares it for certain analytical techniques, such as scanning electron microscopy, where the presence of water would interfere with the imaging process.

Understanding the Trade-offs

While powerful, freeze drying is not the default solution for all preservation needs. It involves specific costs and limitations that must be considered.

A Slow and Energy-Intensive Process

Freeze drying is a meticulous process that can take hours or even days to complete, depending on the sample. It consumes a significant amount of energy compared to simpler dehydration methods like oven drying.

Significant Equipment Investment

Laboratory freeze dryers are complex, specialized machines that represent a considerable capital investment. Their operation and maintenance also require specific technical expertise.

Process Optimization is Crucial

There is no one-size-fits-all protocol for freeze drying. Each type of material requires a carefully optimized cycle of freezing rates, vacuum levels, and temperature changes to prevent damage and ensure successful preservation.

Making the Right Choice for Your Goal

The decision to use freeze drying should be based on the specific requirements for your sample's stability and intended use.

- If your primary focus is maximum integrity and long-term stability: Freeze drying is the superior method for preserving the structure and activity of sensitive biological and chemical compounds.

- If your primary focus is convenient transport and storage: The lightweight, stable product created by freeze drying is ideal for shipping materials that would otherwise require an expensive and complex cold chain.

- If your primary focus is simply water removal at low cost: Faster methods like oven drying or desiccation are more efficient, provided your sample can withstand the higher temperatures and potential structural damage.

Ultimately, freeze drying technology empowers you to effectively pause time, preserving the critical essence of your samples for future discovery.

Summary Table:

| Key Aspect | Description |

|---|---|

| Primary Goal | Preserve sample integrity by removing water without structural damage |

| Core Process | Sublimation (ice to vapor) under vacuum, bypassing liquid phase |

| Key Applications | Long-term bio-specimen storage, pharmaceutical stabilization, sample prep for analysis |

| Main Benefit | Maintains biological/chemical properties for reliable future analysis |

| Considerations | Time-consuming, energy-intensive, requires specialized equipment |

Ready to preserve your most sensitive samples with precision? KINTEK specializes in laboratory freeze drying equipment and consumables designed to maintain the integrity of your biological and chemical materials. Our solutions ensure your research samples remain stable and viable for long-term storage and analysis. Contact our experts today to find the perfect lyophilization system for your lab's specific needs!

Visual Guide

Related Products

- Benchtop Laboratory Freeze Dryer for Lab Use

- Three-dimensional electromagnetic sieving instrument

- Laboratory Hybrid Tissue Grinding Mill

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- Customizable XRD Sample Holders for Diverse Research Applications

People Also Ask

- What is the technical definition of freeze drying? A Deep Dive into Lyophilization and Sublimation

- What are the factors affecting evaporation? Control the Rate of Any Liquid's Vaporization

- How do you evaporate DMSO solvent? Master Gentle, High-Vacuum Techniques for Sensitive Samples

- What are the primary benefits of using a lab freeze dryer in pharmaceutical applications? Enhance Drug Stability and Shelf Life

- What are amorphous materials in freeze drying? The Key to Preventing Product Collapse