The fundamental problem in heat treatment is managing the trade-off between achieving desired material properties and preventing unwanted side effects. At high temperatures, metals become highly reactive with their environment, leading to defects like surface oxidation, while the methods used to prevent these defects introduce their own significant costs, complexities, and material-specific risks.

The core challenge of heat treatment is not simply the heating and cooling cycle itself, but rather the precise control of the furnace atmosphere. An uncontrolled atmosphere degrades the workpiece, while a controlled one introduces significant operational complexity and expense.

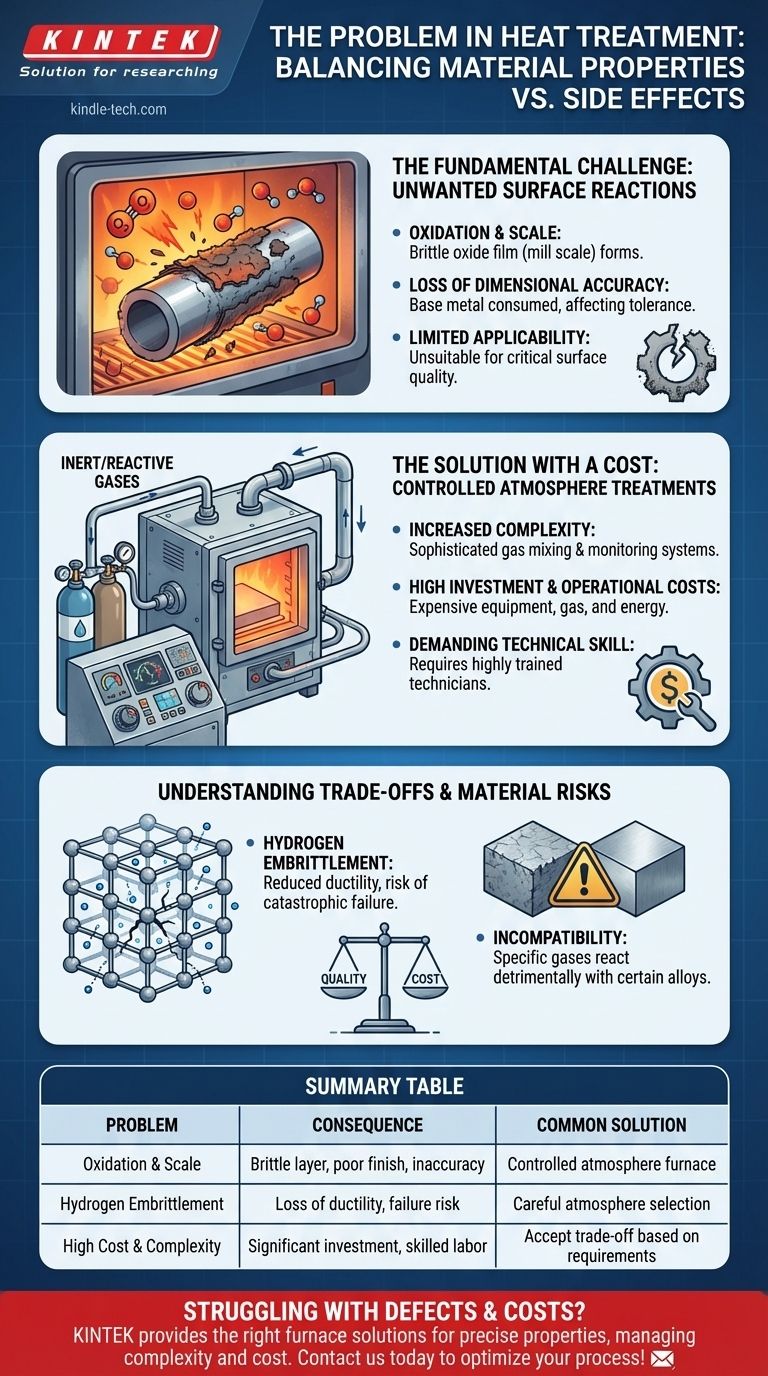

The Fundamental Challenge: Unwanted Surface Reactions

When a metal is heated in an ordinary atmosphere, its surface chemistry is inevitably altered. This is the most common and basic problem in heat treatment.

The Problem of Oxidation and Scale

At elevated temperatures, the metal surface reacts aggressively with oxygen in the air. This chemical reaction forms a brittle, flaky layer known as an oxide film or mill scale.

This oxide layer compromises the integrity of the part. It alters the surface finish, can flake off, and must often be removed through costly secondary processes like sandblasting or acid pickling.

Loss of Dimensional Accuracy

The formation of an oxide film is not just a surface coating; it consumes the base metal. This process can lead to a loss of material and a change in the part's precise dimensions, which is unacceptable for high-tolerance components.

Limited Applicability

Because of these surface degradation issues, heat treatment in an ordinary atmosphere is often unsuitable for finished parts or components where surface quality and dimensional accuracy are critical.

The Solution with a Cost: Controlled Atmosphere Treatments

To prevent oxidation, workpieces can be heat-treated in a sealed furnace where the atmosphere is carefully controlled, often using inert or reactive gases. While effective, this solution introduces a new set of problems.

Increased Equipment Complexity

Controlled atmosphere furnaces are far more complex than their ordinary counterparts. They require sophisticated systems for mixing gases, monitoring composition, and maintaining a sealed environment, which increases the points of potential failure.

High Investment and Operational Costs

The initial investment for this specialized equipment is substantial. Furthermore, the ongoing costs of purchasing specific gases and the energy required to maintain the system make it a much more expensive process.

Demanding Technical Skill

Operating a controlled atmosphere furnace is not a simple task. It requires highly trained technicians who understand the metallurgy, gas chemistry, and safety protocols involved to prevent process failures or dangerous conditions.

Understanding the Trade-offs and Material-Specific Risks

Choosing a heat treatment method is a matter of balancing quality requirements against cost and technical feasibility. Beyond this balance, specific processes carry inherent material risks.

The Risk of Hydrogen Embrittlement

A significant danger in certain controlled atmospheres, particularly those with high hydrogen content, is hydrogen embrittlement. Tiny hydrogen atoms can diffuse into the crystal structure of some steels, severely reducing their ductility and making them brittle and prone to catastrophic failure under stress.

Incompatibility with Certain Materials

Not all materials can be treated in a given controlled atmosphere. The specific gases used can have unintended and detrimental reactions with certain alloying elements, making process selection a critical engineering decision.

The Cost vs. Quality Dilemma

This is the central trade-off. Ordinary atmosphere treatment is cheap but results in a poor surface finish. Controlled atmosphere treatment provides a pristine surface but at a significantly higher cost and level of complexity.

Making the Right Choice for Your Application

The "best" heat treatment process is entirely dependent on the final application of the component. Your decision should be guided by the part's specific requirements.

- If your primary focus is cost-effectiveness for non-critical parts: An ordinary atmosphere treatment is viable, but you must account for necessary post-processing steps like cleaning or machining.

- If your primary focus is high surface integrity and dimensional accuracy: A controlled atmosphere process is necessary, and you must budget for the higher costs and technical oversight required.

- If you are treating high-strength or specialized alloys: You must carefully select an atmosphere that avoids specific risks like hydrogen embrittlement and is chemically compatible with your material.

Understanding these inherent challenges is the first step toward successfully engineering the precise material properties your project demands.

Summary Table:

| Problem | Consequence | Common Solution |

|---|---|---|

| Oxidation & Scale | Brittle surface layer, poor finish, dimensional inaccuracy | Controlled atmosphere furnace |

| Hydrogen Embrittlement | Loss of ductility, risk of catastrophic failure | Careful atmosphere selection |

| High Cost & Complexity | Significant investment in equipment, gases, and skilled labor | Accept trade-off based on part requirements |

Struggling with heat treatment defects and costs? KINTEK specializes in lab equipment and consumables, providing the right furnace solutions to help your laboratory achieve precise material properties while managing complexity and cost. Our experts can help you select the ideal equipment for your specific materials and quality requirements. Contact us today to optimize your heat treatment process!

Visual Guide

Related Products

- Laboratory Rapid Thermal Processing (RTP) Quartz Tube Furnace

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- Graphite Vacuum Furnace High Thermal Conductivity Film Graphitization Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What are the end products of pyrolysis? Turn Waste into Biochar, Oil, and Syngas

- What are some disadvantages of powder metallurgy? Size, Strength, and Complexity Limitations

- What is the purpose of reactive sputtering? Synthesize High-Performance Compound Thin Films

- What is the importance of determining the melting point of a substance? Identify Compounds & Assess Purity

- What important safety precaution should be taken when using a melting point apparatus? Avoid Burns and Explosions

- What is an example of fast pyrolysis? Converting Biomass to Bio-Oil in Under 2 Seconds

- What is sputter coating? A High-Performance Thin Film Deposition Process

- What are some common drying methods used in laboratories and their drawbacks? Choose the Right Method to Protect Your Samples