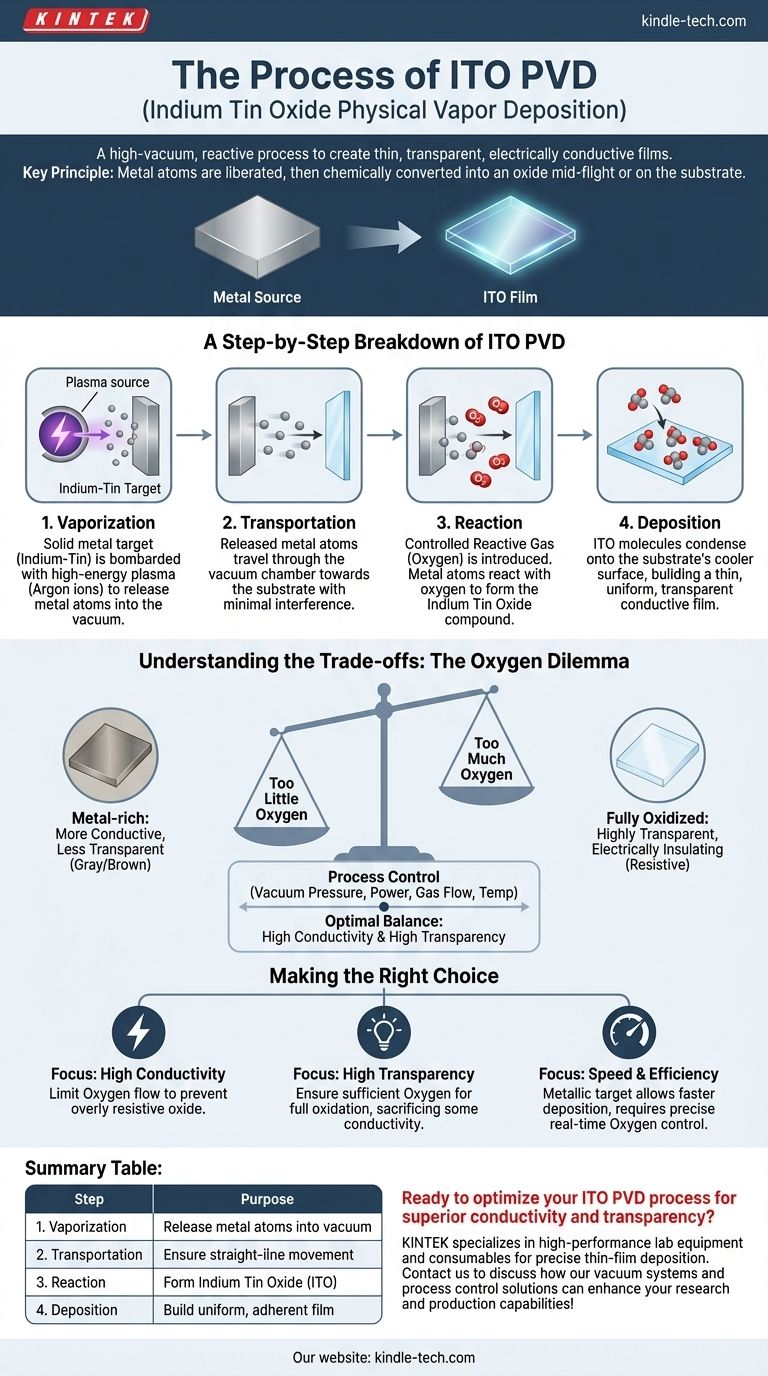

In short, Indium Tin Oxide (ITO) Physical Vapor Deposition (PVD) is a high-vacuum process used to create a thin, transparent, and electrically conductive film. It works by bombarding a source material, typically an Indium-Tin alloy, to release atoms which then travel to a substrate. During this process, oxygen is introduced to react with the metal atoms, forming the desired Indium Tin Oxide compound that deposits onto the substrate as a solid film.

The core principle to grasp is that ITO PVD is not just about depositing a material; it is a carefully controlled reactive process. Metal atoms are first liberated from a source and then chemically converted into an oxide mid-flight or on the substrate surface, creating a new material with unique optical and electrical properties.

The Core Principle: From Metal to Transparent Conductor

PVD is fundamentally a technique for building materials atom-by-atom in a controlled environment. The entire process takes place inside a high-vacuum chamber, which is critical for two reasons.

First, the vacuum ensures purity by removing air and other contaminants that could interfere with the film. Second, the low pressure allows vaporized atoms to travel from the source to the target substrate with few or no collisions.

For ITO, the goal is to create a very specific metal oxide. This requires not just a source material but also a reactive gas, which transforms the deposited metal into a transparent ceramic-like film.

A Step-by-Step Breakdown of ITO PVD

While there are several variations of PVD (like sputtering or evaporation), the process for creating a reactive film like ITO generally follows four distinct stages.

Step 1: Vaporization

The process begins with a solid source material, known as a target. For ITO, this is most often a metallic alloy of indium and tin.

This target is bombarded with a high-energy source, typically a plasma created from an inert gas like argon. The impact from the energetic plasma ions knocks or "sputters" individual atoms of indium and tin off the target, releasing them into the vacuum chamber in a vapor phase.

Step 2: Transportation

Once freed from the target, the metal atoms travel through the low-pressure environment toward the substrate—the material being coated (e.g., glass or plastic).

Because the pressure is so low, these atoms move in a straight line with minimal interference, ensuring they can reach their destination.

Step 3: Reaction

This is the most critical stage for forming ITO. While the indium and tin atoms are in transit, a controlled amount of a reactive gas (oxygen) is introduced into the chamber.

The free indium and tin atoms react with the oxygen atoms. This chemical reaction forms the Indium Tin Oxide compound. This reaction can happen in the space between the target and substrate or on the surface of the substrate itself.

Step 4: Deposition

The newly formed ITO molecules arrive at the substrate and condense onto its cooler surface.

This deposition builds up layer by layer, growing an extremely thin, uniform, and solid film that adheres strongly to the substrate. The final film's properties are a direct result of the control exerted during the previous three steps.

Understanding the Trade-offs

The quality of an ITO film is highly sensitive to the process parameters. Achieving the delicate balance between high electrical conductivity and high optical transparency is the central challenge.

The Oxygen Dilemma

The amount of oxygen introduced during the reaction phase is critical.

Too little oxygen results in a "metal-rich" film that is more conductive but less transparent, often appearing grayish or brownish. Too much oxygen creates a fully oxidized, highly transparent film that is electrically insulating (highly resistive).

Process Control is Everything

Achieving a high-quality ITO film requires precise control over multiple variables. These include the vacuum pressure, the power applied to the target, the flow rates of both the argon and oxygen gas, and the temperature of the substrate. Even minor deviations can significantly alter the film's performance.

Making the Right Choice for Your Goal

The parameters of the ITO PVD process must be tuned based on the desired outcome for the final product.

- If your primary focus is high conductivity: You must carefully limit the oxygen flow to the minimum required for transparency, preventing the formation of an overly resistive, fully stoichiometric oxide.

- If your primary focus is high transparency: You must ensure a sufficient oxygen supply to fully oxidize the metal atoms, sacrificing some conductivity to maximize light transmission.

- If your primary focus is process speed and efficiency: Using a metallic Indium-Tin target allows for higher deposition rates, but demands more sophisticated real-time control of the reactive oxygen gas.

Ultimately, mastering the ITO PVD process is an exercise in balancing competing properties to create a high-performance transparent conductive oxide.

Summary Table:

| Step | Key Action | Purpose |

|---|---|---|

| 1. Vaporization | Sputter indium-tin target with argon plasma | Release metal atoms into the vacuum chamber |

| 2. Transportation | Atoms travel through low-pressure environment | Ensure straight-line movement to the substrate |

| 3. Reaction | Introduce oxygen gas to react with metal atoms | Form Indium Tin Oxide (ITO) compound |

| 4. Deposition | ITO molecules condense on substrate surface | Build uniform, adherent transparent conductive film |

Ready to optimize your ITO PVD process for superior conductivity and transparency?

KINTEK specializes in high-performance lab equipment and consumables for precise thin-film deposition. Whether you're developing displays, touchscreens, or optoelectronic devices, our expertise in vacuum systems and process control can help you achieve the perfect balance between electrical and optical properties.

Contact us today to discuss how KINTEK's solutions can enhance your laboratory's thin-film research and production capabilities!

Visual Guide

Related Products

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Laboratory CVD Boron Doped Diamond Materials

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

People Also Ask

- How does MPCVD work? A Guide to Low-Temperature, High-Quality Film Deposition

- What are the limitations of diamonds? Beyond the Myth of Perfection

- What is the frequency of MPCVD? A Guide to Choosing 2.45 GHz vs. 915 MHz for Your Application

- What are the advantages of microwave plasma? Faster, Purer Processing for Demanding Applications

- What is MPCVD? Unlock Atom-by-Atom Precision for High-Purity Materials