At its core, Spark Plasma Sintering (SPS) is a high-speed consolidation technique. It uses a pulsed direct electric current and uniaxial pressure to transform powders into a dense solid. The process typically involves four primary stages: creating a vacuum, applying pressure, rapid resistive heating via the pulsed current, and a final cooling stage.

The fundamental advantage of SPS lies in its unique heating mechanism. By passing a high-amperage, low-voltage current directly through the conductive die and the powder, it generates intense, localized heat at particle contact points, enabling densification in minutes rather than hours.

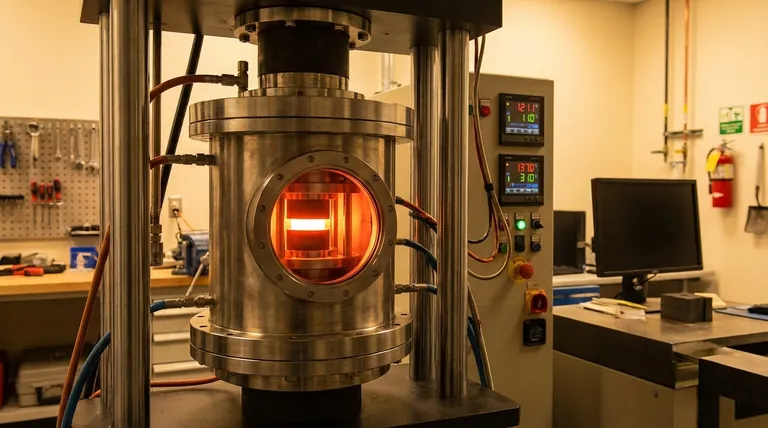

Deconstructing the SPS Process

To truly understand SPS, we must look at how each stage contributes to the final material properties. The process is a carefully orchestrated sequence performed within a specialized press.

Stage 1: Sample Loading and Evacuation

First, the powder material is loaded into a conductive die, which is almost always made of graphite. This die assembly is then placed between two electrodes inside a vacuum chamber.

The chamber is evacuated to remove atmospheric gases. This crucial step prevents the oxidation of the powder material and the graphite tooling, which would otherwise be compromised at the high processing temperatures.

Stage 2: Application of Uniaxial Pressure

Once the desired vacuum is achieved, a uniaxial pressure is applied through the electrodes, which act as press rams. This initial pressure compacts the powder, increasing particle-to-particle contact.

This ensures good electrical conductivity throughout the powder compact, which is essential for the subsequent heating stage. The pressure is maintained or increased throughout the heating cycle to aid in densification.

Stage 3: Pulsed Current and Rapid Heating

This is the defining stage of the SPS process. A high-power pulsed Direct Current (DC) is applied directly to the electrodes. The current flows through the graphite die and, critically, through the powder sample itself.

This creates rapid heating through several mechanisms. The primary effect is Joule heating (resistive heating). Additionally, at the contact points between individual powder particles, spark discharges can occur, generating localized, momentary high-temperature plasma. This effect cleans the particle surfaces and dramatically accelerates the formation of "necks" or bonds between them.

Stage 4: Consolidation and Cooling

As the temperature rapidly increases to the target sintering point, the material softens and densifies under the constant pressure, eliminating porosity. The process is held at this temperature for a very short period—often just a few minutes.

Once the desired density is reached, the current is turned off. The system then cools down rapidly, locking in the fine-grained microstructure that is a hallmark of the SPS technique.

What Makes SPS Fundamentally Different?

SPS is not simply a faster version of traditional hot pressing. Its direct heating method creates conditions that are fundamentally different from those in a conventional furnace.

The Role of Direct Current Heating

In a traditional hot press, a furnace externally heats the die and sample, a slow process that relies on thermal conduction. SPS uses the material and die as their own heating elements. This internal, direct heating is incredibly efficient and fast.

The "Spark Plasma" Effect

The pulsed current generates spark discharges in the voids between powder particles. This generates localized temperatures far higher than the overall sample temperature. This phenomenon cleans particle surfaces of contaminants and activates them for bonding, a key factor in the rapid sintering speed.

Unprecedented Speed Inhibits Grain Growth

The most significant outcome of SPS is speed. Heating rates can be hundreds of degrees Celsius per minute. By minimizing the time the material spends at high temperatures, SPS effectively inhibits grain growth, allowing for the production of fully dense materials with exceptionally fine, and often novel, microstructures.

Understanding the Trade-offs and Considerations

While powerful, SPS is not a universal solution. It comes with its own set of constraints that are critical to understand for successful application.

Material and Tooling Constraints

The standard SPS process requires both the die and, ideally, the sample to be electrically conductive. While insulators can be sintered, it requires careful die design as the heat must transfer from the die to the powder. The process is also largely limited to the use of graphite tooling, which has temperature and pressure limitations.

Temperature Gradients

Because heating originates from the current flow, achieving perfect temperature uniformity can be challenging. Temperature gradients can exist between the surface and the core of a large sample, which must be accounted for in the process design.

The "Plasma" Debate

It is important to note that while the term "Spark Plasma Sintering" is widely used, the existence of a sustained, bulk plasma throughout the sample is a subject of scientific debate. However, the practical effects of spark discharge and localized heating at particle interfaces are well-documented and are responsible for the technique's unique advantages.

How to Apply This to Your Goal

Choosing a sintering method depends entirely on the desired outcome for your material.

- If your primary focus is rapid prototyping or developing novel materials: SPS is the ideal choice due to its extreme speed and its ability to create unique, non-equilibrium microstructures.

- If your primary focus is producing high-density, nano-structured parts: SPS excels at achieving full densification while preserving the fine grain size that is crucial for enhanced mechanical properties.

- If your primary focus is cost-effective production of simple, large components: Traditional hot-press sintering or conventional furnace sintering may be more suitable if the unique microstructural benefits of SPS are not required.

Ultimately, Spark Plasma Sintering provides an unparalleled level of control over a material's microstructure through its unique and rapid energy delivery.

Summary Table:

| Stage | Key Action | Purpose |

|---|---|---|

| 1. Sample Loading & Evacuation | Load powder into graphite die, create vacuum | Prevent oxidation, prepare for heating |

| 2. Apply Pressure | Apply uniaxial pressure through electrodes | Compact powder, ensure electrical contact |

| 3. Pulsed Current Heating | Apply pulsed DC current directly to powder | Rapid heating via Joule heating & spark discharges |

| 4. Consolidation & Cooling | Hold temperature briefly, then rapid cool | Achieve full density while inhibiting grain growth |

Ready to achieve superior material consolidation with Spark Plasma Sintering?

At KINTEK, we specialize in advanced lab equipment for materials research and development. Our expertise in sintering technologies can help you:

- Develop novel materials with unique microstructures

- Achieve full densification while preserving fine grain sizes

- Accelerate your R&D with rapid processing capabilities

Whether you're working with conductive powders or specialized materials, our team can provide the right SPS solution for your laboratory needs.

Contact KINTEK today to discuss how Spark Plasma Sintering can transform your materials research!

Visual Guide

Related Products

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

- Vacuum Dental Porcelain Sintering Furnace

- Laboratory Sterilizer Lab Autoclave Vertical Pressure Steam Sterilizer for Liquid Crystal Display Automatic Type

People Also Ask

- Why is it important to autoclave the prepared reagents before using? Ensure Sterility and Reliable Results

- What is a lab autoclave? Your Guide to Sterilization with Pressurized Steam

- Do you need to autoclave glassware? A Guide to Sterilization vs. Cleaning

- What is the use of autoclave in medical? The Critical Role of Sterilization in Patient Safety

- Can autoclave sterilize liquid? Master Safe and Effective Liquid Sterilization