In essence, twin screw granulation is a continuous manufacturing process that transforms fine powders into denser, more uniform granules. It achieves this by using the intense mixing and controlled heating generated by two intermeshing, co-rotating screws inside a barrel to melt a binding agent, which then agglomerates the active pharmaceutical ingredient (API) and other excipients.

The core value of twin screw granulation is its shift from unpredictable batch processing to a highly controlled, continuous operation. This allows for the production of granules with superior consistency and quality, which is a critical goal in modern pharmaceutical manufacturing.

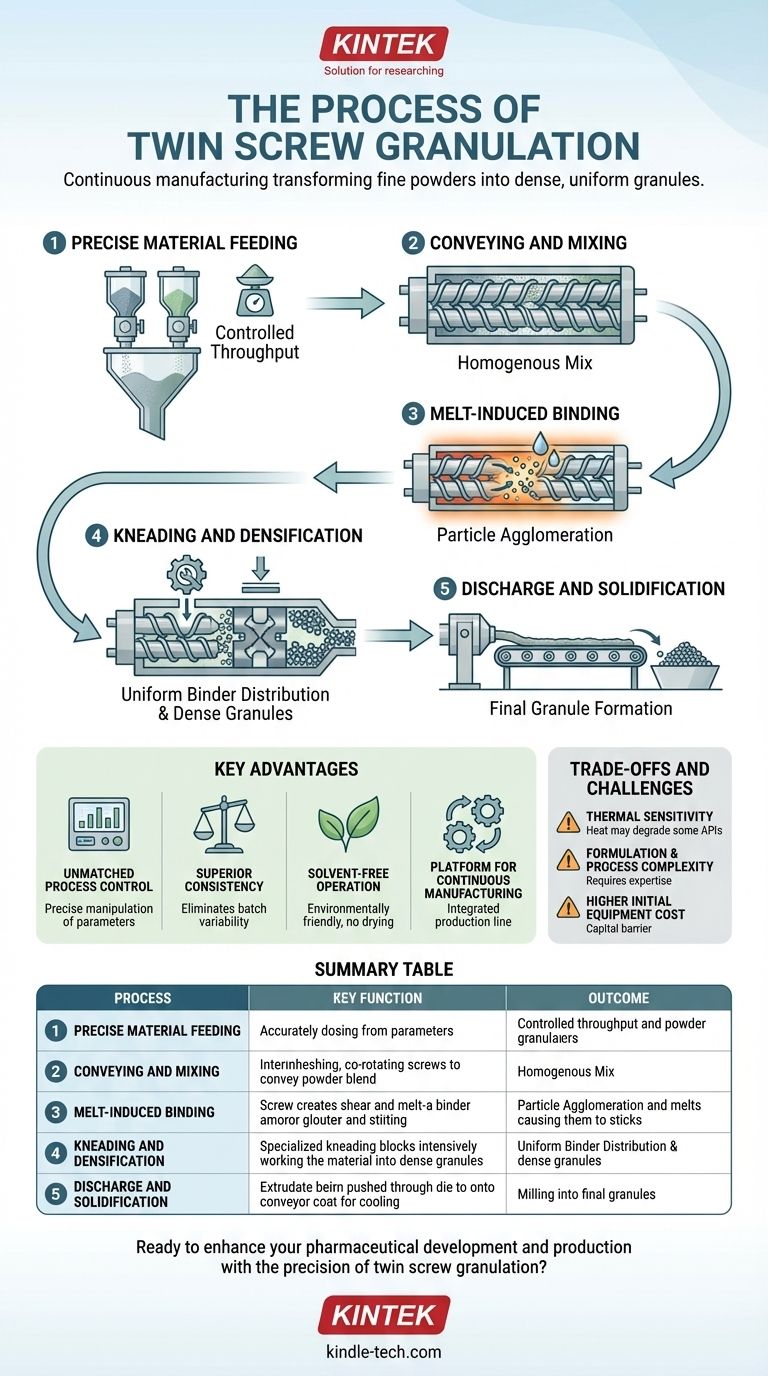

The Core Mechanism: From Powder to Granule

Twin screw granulation operates as a miniature, continuous production line. The powder blend travels through distinct zones within the extruder barrel, each performing a specific function.

Step 1: Precise Material Feeding

The process begins with one or more gravimetric feeders that accurately dose the powder blend—comprising the API and excipients like binders—into the extruder. The feed rate is a critical parameter that dictates the throughput of the entire system.

Step 2: Conveying and Mixing

Once inside the barrel, the rotating screws immediately convey the material forward. The geometry of the screw elements ensures the initial dry blending of the components, creating a homogenous mix before the primary granulation phase.

Step 3: Melt-Induced Binding

This is the heart of the process. As the material moves into a heated section of the barrel, two forces act upon it: external heat from the barrel and intense shear generated by the screws. This energy melts a low-melting-point binder within the powder blend.

The molten binder acts as a liquid bridge, wetting the surfaces of the other particles and causing them to stick together, or agglomerate.

Step 4: Kneading and Densification

The screws are not uniform; they are assembled from different elements. Specialized "kneading blocks" are placed after the melting zone. These elements intensively work the wet mass, distributing the molten binder uniformly and compacting the material into dense, homogenous granules.

Step 5: Discharge and Solidification

The granulated, plastic-like mass is then conveyed to the end of the extruder and discharged through a die. Upon exiting, the extrudate is typically cooled on a conveyor belt and then milled to achieve the final desired particle size distribution for downstream processes like tableting.

Key Advantages Over Traditional Methods

The growing interest in twin screw granulation is driven by its significant advantages over conventional batch-based methods like wet granulation.

Unmatched Process Control

Operators have direct control over critical process parameters like screw speed, barrel temperature profile, and feed rate. This allows for precise manipulation of the energy input, ensuring the process remains in a steady, predictable state.

Superior Consistency and Uniformity

Because it's a continuous process, every portion of the material experiences nearly identical thermal and shear history. This eliminates the batch-to-batch variability common in traditional mixers, resulting in granules with highly consistent quality.

Solvent-Free Operation

Twin screw melt granulation uses a meltable binder instead of a granulation liquid (like water or organic solvents). This eliminates the costly and time-consuming drying step, reduces safety risks, and is more environmentally friendly.

Platform for Continuous Manufacturing

This technology is a cornerstone of modern continuous manufacturing initiatives in the pharmaceutical industry. It enables a seamless, integrated production line from powder to final tablet, reducing facility footprint and accelerating development timelines.

Understanding the Trade-offs and Challenges

While powerful, twin screw granulation is not a universal solution. It requires careful consideration of its limitations.

Thermal Sensitivity of Ingredients

The process relies on heat. If the active ingredient (API) is thermally labile or degrades at the processing temperature required to melt the binder, this method may not be suitable.

Formulation and Process Complexity

Developing a robust formulation and process requires significant expertise. Selecting the right binder, screw configuration, and temperature profile is a multi-variable problem that demands a deep understanding of material science and process engineering.

Higher Initial Equipment Cost

The initial capital investment for a twin screw extruder and its associated feeding systems can be higher than for traditional batch granulation equipment, which can be a barrier for some applications.

Making the Right Choice for Your Goal

Applying twin screw granulation effectively depends on your specific objective.

- If your primary focus is rapid formulation development: Use a lab-scale extruder to quickly screen different binders and formulations with very small amounts of material.

- If your primary focus is consistent commercial production: Leverage the process control and continuous nature of TSG to ensure high product quality and eliminate batch-to-batch deviations.

- If your primary focus is enabling difficult formulations: Employ TSG to create amorphous solid dispersions, which can significantly improve the bioavailability of poorly soluble drugs.

Ultimately, twin screw granulation empowers pharmaceutical scientists with a level of control and consistency that was previously unattainable with batch processes.

Summary Table:

| Process Step | Key Function | Key Outcome |

|---|---|---|

| Material Feeding | Precise dosing of API & excipients | Controlled throughput and formulation accuracy |

| Conveying & Mixing | Initial dry blending of components | Homogenous powder mix |

| Melt-Induced Binding | Application of heat and shear to melt binder | Particle agglomeration via liquid bridges |

| Kneading & Densification | Intensive working of the wet mass | Uniform binder distribution and dense granules |

| Discharge & Solidification | Extrusion through a die and cooling | Final granule formation with desired particle size |

Ready to enhance your pharmaceutical development and production with the precision of twin screw granulation?

KINTEK specializes in providing advanced laboratory equipment and consumables. Our expertise can help you leverage continuous processing technologies to achieve superior product consistency, accelerate development timelines, and overcome formulation challenges like improving drug bioavailability.

Contact our experts today to discuss how our solutions can meet your specific laboratory needs and drive your projects forward.

Visual Guide

Related Products

- Powerful Plastic Crusher Machine

- Laboratory Sterilizer Lab Autoclave Herbal Powder Sterilization Machine for Plant

- Liquid Nitrogen Cryogenic Grinder Mill Cryomill Airflow Ultrafine Pulverizer

- Single Punch Tablet Press Machine and Mass Production Rotary Tablet Punching Machine for TDP

- Automatic Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press 25T 30T 50T

People Also Ask

- What factors influence the size of the product in the ball mill? Master Grinding Media, Speed, and Feed for Precision

- How does a ball mill reduce particle size? Master Particle Size Reduction for Your Lab

- How does grinding process work? Master Particle Size Reduction for Superior Materials

- What is the difference between grinding and pulverizing? Achieve the Perfect Particle Size for Your Application

- What is the purpose of a hammer mill? High-Impact Size Reduction for Diverse Materials