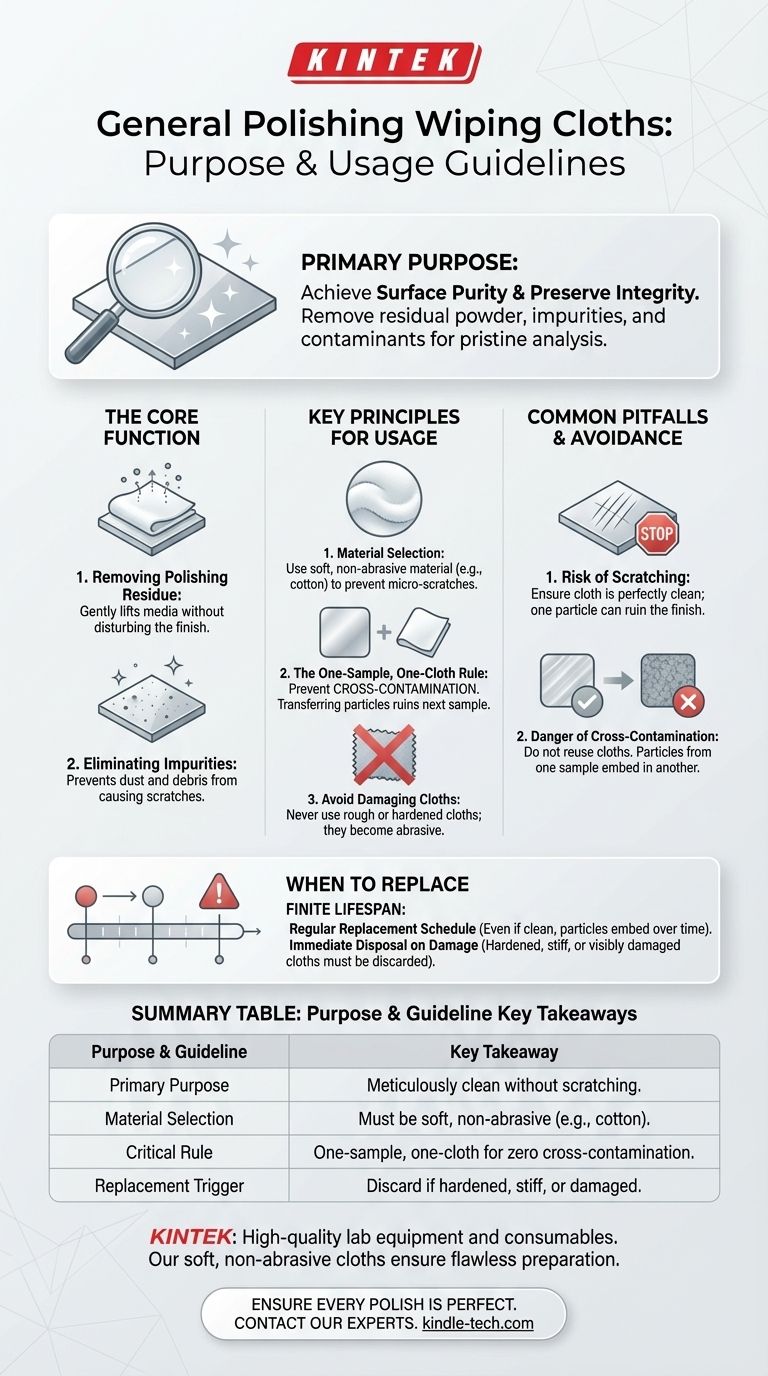

The primary purpose of a general polishing wiping cloth is to meticulously clean a sample's surface after a polishing stage. It is specifically designed to remove residual polishing powder, loose impurities, and other contaminants, ensuring the surface is pristine for subsequent analysis or processing.

The core principle is not just cleaning, but preservation. A polishing cloth's true function is to maintain the integrity of a meticulously prepared surface by preventing scratches and eliminating cross-contamination between samples.

The Core Function: Achieving Surface Purity

The final wipe-down is a critical, not incidental, step in the polishing workflow. It ensures that what you observe or measure next is the true surface of the sample, not an artifact left behind by the process.

Removing Polishing Residue

After polishing, a fine layer of polishing medium (like powder or slurry) remains on the surface. The wiping cloth is used to gently and completely lift this residue away without disturbing the underlying finish.

Eliminating Impurities

The cloth also removes any other foreign matter, such as dust or debris, that may have settled on the sample. This prevents these particles from causing scratches or interfering with microscopic examination.

Key Principles for Proper Usage

Using the correct technique is as important as the cloth itself. The goal is to avoid introducing new defects during the final cleaning step.

Material Selection is Critical

A polishing cloth must be made of a soft, non-abrasive material, with cotton being a common and effective choice. The texture must be gentle enough to not create micro-scratches on the delicate, freshly polished surface.

The One-Sample, One-Cloth Rule

To prevent cross-contamination, a cloth used on one sample must never be used on another. Transferring abrasive particles or material from a previous sample can ruin the finish of the next one.

Avoiding Damaging Cloths

Never use a rough or hardened cloth. Any stiffness or embedded debris in the cloth transforms it from a cleaning tool into an abrasive one, which will inevitably scratch the sample surface.

Common Pitfalls and How to Avoid Them

The most significant risks in this final stage are scratching and contamination. Both are entirely preventable by adhering to strict protocols.

The Risk of Scratching

The most common mistake is using a cloth that is not perfectly clean or has a rough texture. A single abrasive particle trapped in the cloth's fibers can create a significant scratch, forcing you to repeat the final polishing steps.

The Danger of Cross-Contamination

Reusing cloths is a false economy. If you are preparing different materials (e.g., a hard ceramic followed by a soft metal), transferring microscopic particles from the first sample via the cloth can embed them in the second, compromising its integrity and invalidating any analytical results.

When to Replace Your Cloth

A cloth's lifespan is finite. It is essential to have a clear replacement protocol to maintain quality.

Regular Replacement Schedule

Even if a cloth appears clean, it should be replaced regularly as part of a standard procedure. Microscopic particles can become embedded in the fibers over time.

Immediate Disposal on Damage

If a cloth becomes hardened, stiff, or visibly damaged in any way, it must be discarded immediately. A hardened cloth has lost its softness and poses a high risk of scratching the sample.

Making the Right Choice for Your Goal

Your specific objective dictates how strictly these rules must be followed.

- If your primary focus is quantitative analysis (e.g., microscopy, hardness testing): Adhere to the one-sample, one-cloth rule without exception to guarantee zero cross-contamination.

- If your primary focus is aesthetic finish on durable materials: You must still prioritize using a soft, clean cloth and replace it immediately if it feels hardened or rough to the touch.

Ultimately, disciplined use of the polishing cloth protects the significant time and effort invested in preparing your sample.

Summary Table:

| Purpose & Guideline | Key Takeaway |

|---|---|

| Primary Purpose | To meticulously clean a sample's surface after polishing, removing residue and impurities without scratching. |

| Material Selection | Must be soft, non-abrasive (e.g., cotton) to preserve surface integrity. |

| Critical Rule | One-sample, one-cloth to prevent cross-contamination. |

| Replacement Trigger | Discard immediately if cloth becomes hardened, stiff, or damaged. |

Protect your sample integrity and analytical results with the right supplies.

KINTEK specializes in high-quality lab equipment and consumables, including the soft, non-abrasive wiping cloths essential for flawless sample preparation. Our products are designed to help laboratories like yours prevent cross-contamination and achieve reliable, repeatable results.

Ensure every polish is perfect. Contact our experts today to find the ideal consumables for your specific application!

Visual Guide

Related Products

- Metallographic Specimen Mounting Machine for Laboratory Materials and Analysis

- Small Lab Rubber Calendering Machine

- Lab Sterile Slapping Type Homogenizer for Tissue Mashing and Dispersing

- Automatic Lab Cold Isostatic Press CIP Machine Cold Isostatic Pressing

- Custom PTFE Teflon Parts Manufacturer Corrosion Resistant Cleaning Rack Flower Basket

People Also Ask

- What are the advantages of an electrolytic polishing device for EK-181 steel TEM samples? Ensure Peak Sample Integrity

- What role do laboratory grinding and polishing systems play in nitriding? Ensure Superior Mirror-Finish & Ion Penetration

- What is the purpose of using epoxy resin and laboratory mounting equipment? Precision in U71Mn Weld Area Analysis

- What is the general procedure and what precautions should be taken during the polishing process? Achieve a Flawless Electrode Finish

- What is the difference between hot mounting and cold mounting? Choose the Right Method for Your Sample