At its core, a muffle furnace is designed for one primary purpose: to heat materials to very high temperatures within a completely isolated, contaminant-free environment. Unlike a simple oven, its design separates the sample from the heating elements and any potential byproducts of combustion, ensuring that the material itself is all that remains for analysis or treatment.

The true value of a muffle furnace isn't just its ability to reach high temperatures; it's the ability to perform processes like ashing and heat-treating with absolute certainty that the sample will not be contaminated by the heating process itself.

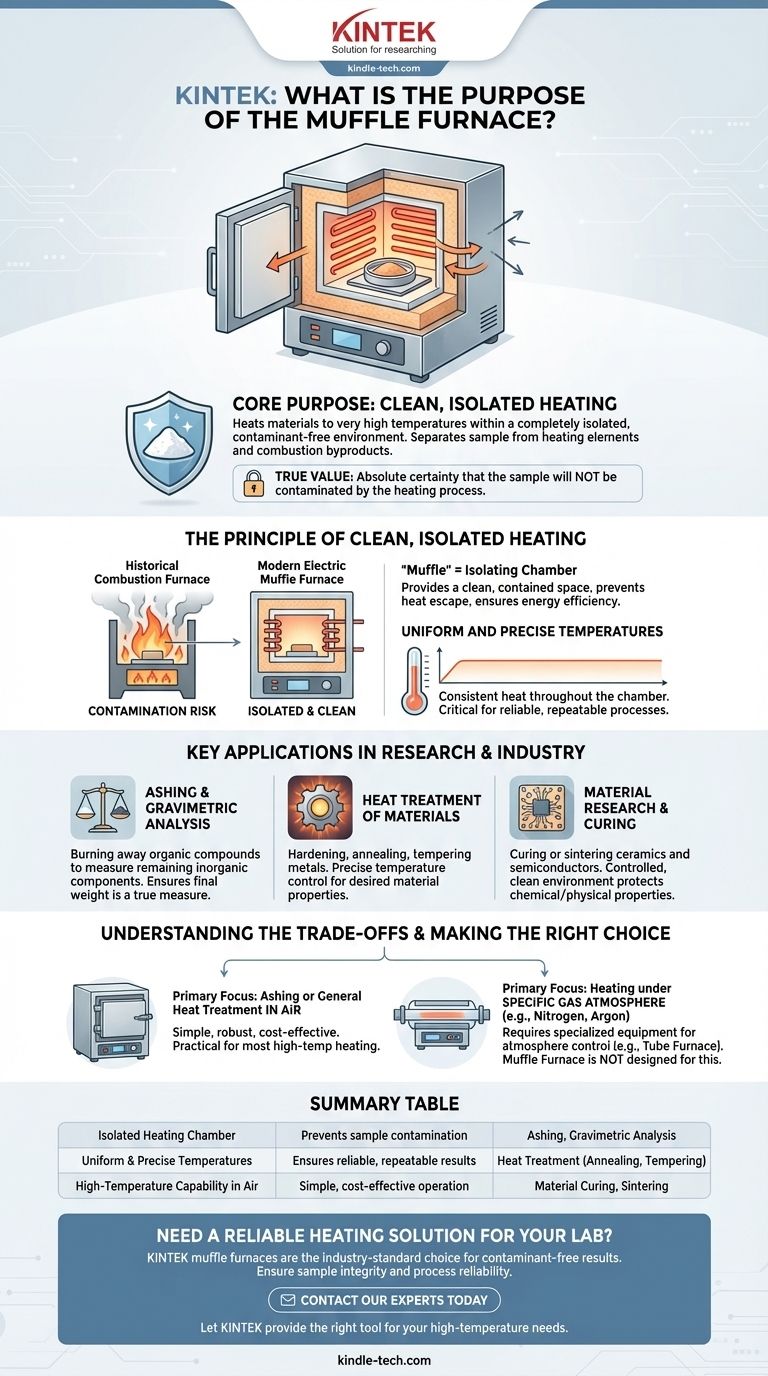

The Principle of Clean, Isolated Heating

To understand the purpose of a muffle furnace, it's essential to grasp its core design principle: isolation. This is what separates it from other high-temperature ovens.

What "Muffle" Means

The term "muffle" refers to the chamber or enclosure that isolates the sample. In historical furnaces, this muffle protected the material from the flames and combustion gases of the heat source.

In modern electric furnaces, there is no combustion. Instead, the insulating chamber that contains the heating coils and the sample is still called the muffle. Its job is to provide a clean, contained space and prevent heat from escaping, ensuring energy efficiency.

Uniform and Precise Temperatures

A key requirement in laboratory work is temperature uniformity and precision. Muffle furnaces, also known as chamber or box furnaces, are engineered to provide consistent heat throughout the entire chamber.

This allows for reliable, repeatable processes, which is critical for scientific research and quality control applications where exact temperature profiles must be followed.

Key Applications in Research and Industry

The combination of high heat and a clean environment makes the muffle furnace a standard piece of equipment for several specific tasks.

Ashing and Gravimetric Analysis

This is the most common application. Ashing is the process of completely burning away organic compounds in a sample to measure the weight of the remaining inorganic components (the "ash").

Because the furnace introduces no external contaminants, researchers can be confident that the final weight is a true measure of the inorganic material present in the original sample.

Heat Treatment of Materials

Muffle furnaces are widely used for the heat treatment of various materials. This includes processes like hardening, annealing, and tempering metals, where precise temperature control is critical to achieving the desired material properties.

Material Research and Curing

In fields like ceramics and semiconductor development, muffle furnaces are used to cure or sinter materials at high temperatures. The controlled, clean environment ensures that the chemical and physical properties of the final product are not compromised.

Understanding the Trade-offs

While incredibly useful, the muffle furnace is not the right tool for every high-temperature job. Its primary limitation defines its purpose.

Atmosphere Control

A standard muffle furnace is designed for heating materials in the presence of ambient air. It is not built to maintain a vacuum or to introduce specific gas atmospheres (like nitrogen or argon).

For applications that require heating in an inert or controlled gas environment, a different piece of equipment, such as a tube furnace, is necessary.

Simplicity and Cost-Effectiveness

The lack of complex atmosphere control systems makes the muffle furnace a relatively simple, robust, and cost-effective solution. For the vast majority of applications requiring high-temperature heating in air, it is the most practical and efficient choice.

Making the Right Choice for Your Process

Selecting the right heating equipment depends entirely on your end goal.

- If your primary focus is determining inorganic content (ashing): The muffle furnace is the industry-standard tool for this exact purpose.

- If your primary focus is general heat treatment in air: The furnace's uniform heating and simplicity make it an excellent, cost-effective choice for processes like annealing or tempering.

- If your primary focus is heating under a specific gas atmosphere (e.g., nitrogen or argon): The muffle furnace is the wrong tool; you need a furnace specifically designed for atmosphere control, like a tube furnace.

Ultimately, a muffle furnace provides a reliable and uncomplicated solution for any high-temperature application where sample purity and process integrity are paramount.

Summary Table:

| Key Feature | Benefit | Primary Application |

|---|---|---|

| Isolated Heating Chamber | Prevents sample contamination | Ashing, Gravimetric Analysis |

| Uniform & Precise Temperatures | Ensures reliable, repeatable results | Heat Treatment (Annealing, Tempering) |

| High-Temperature Capability in Air | Simple, cost-effective operation | Material Curing, Sintering |

Need a reliable heating solution for your lab?

A muffle furnace from KINTEK is the industry-standard choice for achieving contaminant-free results in applications like ashing and heat treatment. Our robust and precise furnaces ensure your sample integrity and process reliability.

Let KINTEK, a specialist in lab equipment, provide the right tool for your high-temperature needs.

Contact our experts today to discuss how a KINTEK muffle furnace can enhance your laboratory's capabilities!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ Muffle Oven Furnace for Laboratory

- 1800℃ Muffle Oven Furnace for Laboratory

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- What do you use a muffle furnace for? Achieve Contamination-Free High-Temperature Processing

- What is the working principle of laboratory muffle furnace? Achieve Contamination-Free High-Temperature Processing

- How do you clean a muffle furnace? A Step-by-Step Guide to Ensure Safety and Longevity

- What is the working principle of a muffle furnace? Achieve Precise, Contamination-Free Heating

- What is difference between hot air oven and muffle furnace? Key Differences in Temperature and Applications