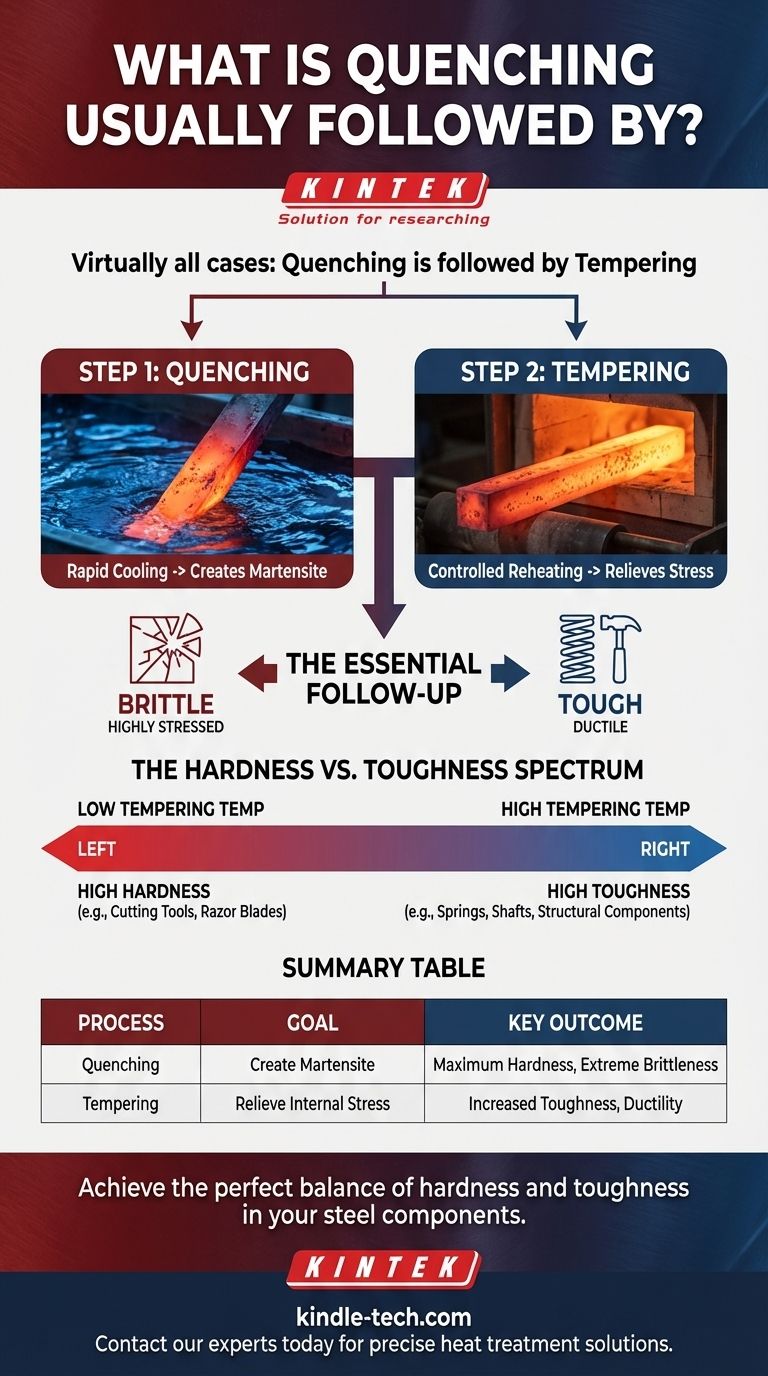

In virtually all cases, the quenching operation is followed by tempering. While quenching achieves the primary goal of creating a very hard material structure, it leaves the metal in a highly stressed and brittle state, making it unsuitable for most practical applications. Tempering is the critical subsequent step that reduces this brittleness and imparts the necessary toughness.

Quenching is a means to an end, not the final step. It creates maximum hardness at the cost of extreme brittleness. The essential follow-up process, tempering, is a controlled reheating that transforms this brittle hardness into functional toughness.

Why Quenching Alone is Not Enough

To understand why tempering is necessary, we must first look at what quenching does to the internal structure of steel. The entire purpose of this two-step process is to precisely control the final properties of the material.

The Goal of Quenching: Creating Martensite

When steel is heated to a high temperature (a process called austenitizing), its carbon atoms dissolve into a specific crystal structure. The goal of quenching is to cool the steel so rapidly that these carbon atoms do not have time to move and form softer structures.

This rapid cooling traps the carbon atoms, creating a new, highly strained, and distorted crystal structure known as martensite. Martensite is what gives quenched steel its exceptional hardness and wear resistance.

The Unintended Consequence: Extreme Brittleness

The trapped carbon atoms that create the hardness of martensite also generate immense internal stress within the material's crystal lattice.

This internal stress makes the steel extremely brittle. A freshly quenched, untempered piece of high-carbon steel is so fragile that it can shatter like glass if dropped or struck. This brittleness renders it useless for any application that involves impact, vibration, or flexing.

The Role of Tempering: Restoring Toughness

Tempering is a heat treatment process designed specifically to address the brittleness induced by quenching. It involves reheating the hardened steel to a precise temperature below its critical point, holding it there for a period, and then cooling it.

How Tempering Relieves Stress

The controlled application of heat during tempering gives the trapped carbon atoms just enough energy to move slightly. This allows them to precipitate out of the distorted martensite structure and form tiny particles of hard carbides.

This subtle rearrangement dramatically relieves the internal stresses that were locked into the material during the quench.

The Result: A Balance of Properties

The primary outcome of tempering is a significant increase in toughness and ductility. While there is a slight reduction in peak hardness, this trade-off is essential for creating a functional component.

The final material is a composite structure—tempered martensite—that retains most of its hardness while gaining the durability required to withstand real-world service conditions.

Understanding the Trade-offs

The relationship between quenching and tempering is fundamentally about balancing competing properties. The key variable that controls this balance is the tempering temperature.

The Hardness vs. Toughness Spectrum

The specific temperature chosen for tempering dictates the final properties of the steel. This is not a one-size-fits-all process.

A low tempering temperature (e.g., 150-200°C / 300-400°F) relieves just enough stress to prevent shattering but retains very high hardness. This is ideal for cutting tools or bearings.

A high tempering temperature (e.g., 500-650°C / 930-1200°F) results in a much tougher and more ductile material, but with a more significant reduction in hardness. This is suitable for springs, shafts, and structural components.

Avoiding Improper Procedures

Following a precise temperature and time recipe is critical. For example, some alloys can suffer from "temper embrittlement" if they are held in or cooled slowly through certain temperature ranges, which can unexpectedly make them brittle again. This highlights the importance of controlled, well-understood procedures.

Matching the Process to the Application

The decision of what tempering temperature to use is driven entirely by the intended use of the component.

- If your primary focus is maximum hardness and wear resistance (e.g., files, razor blades): A low-temperature temper is used to retain as much of the as-quenched hardness as possible.

- If your primary focus is a balance of high strength and impact resistance (e.g., axles, hammers, structural steel): A mid-to-high-range tempering temperature is chosen to achieve significant toughness.

- If your primary focus is maximum toughness and ductility (e.g., certain fasteners or springs): A very high tempering temperature is used, sacrificing more hardness for superior resilience.

By mastering the partnership between quenching and tempering, you gain precise control over a material's final mechanical properties.

Summary Table:

| Process | Goal | Key Outcome |

|---|---|---|

| Quenching | Rapid cooling to create martensite | Maximum hardness, but extreme brittleness |

| Tempering | Reheating to relieve internal stress | Increased toughness and ductility |

Achieve the perfect balance of hardness and toughness in your steel components.

At KINTEK, we specialize in the precise lab equipment and consumables needed for controlled heat treatment processes like quenching and tempering. Whether you are developing cutting tools, springs, or structural parts, our solutions help you achieve the exact material properties required for your application.

Contact our experts today via our Contact Form to discuss how we can support your laboratory's material science and heat treatment needs.

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

- Vertical Laboratory Tube Furnace

- Graphite Vacuum Furnace High Thermal Conductivity Film Graphitization Furnace

People Also Ask

- What are the advantages of vacuum hardening? Achieve Superior Precision and Cleanliness for Critical Components

- What materials are used in a vacuum furnace? A Guide to Hot Zone Materials and Processed Metals

- What is the vacuum heat treatment cycle? Achieve Superior Material Purity and Precision

- What does a vacuum furnace do? Achieve High-Purity Heat Treatment for Superior Components

- Where are vacuum furnaces used? Essential for High-Purity Heat Treatment in Critical Industries