The recommended pre-treatment for a glassy carbon sheet is a multi-step mechanical polishing process performed on a chamois cloth. The standard procedure involves polishing the surface with a sequence of alumina (Al₂O₃) suspensions, starting with a larger grit and moving to progressively finer ones. A typical sequence is 1.0 µm, followed by 0.3 µm, and finishing with 0.05 µm, with thorough rinsing between each step to achieve a scratch-free, mirror-like finish.

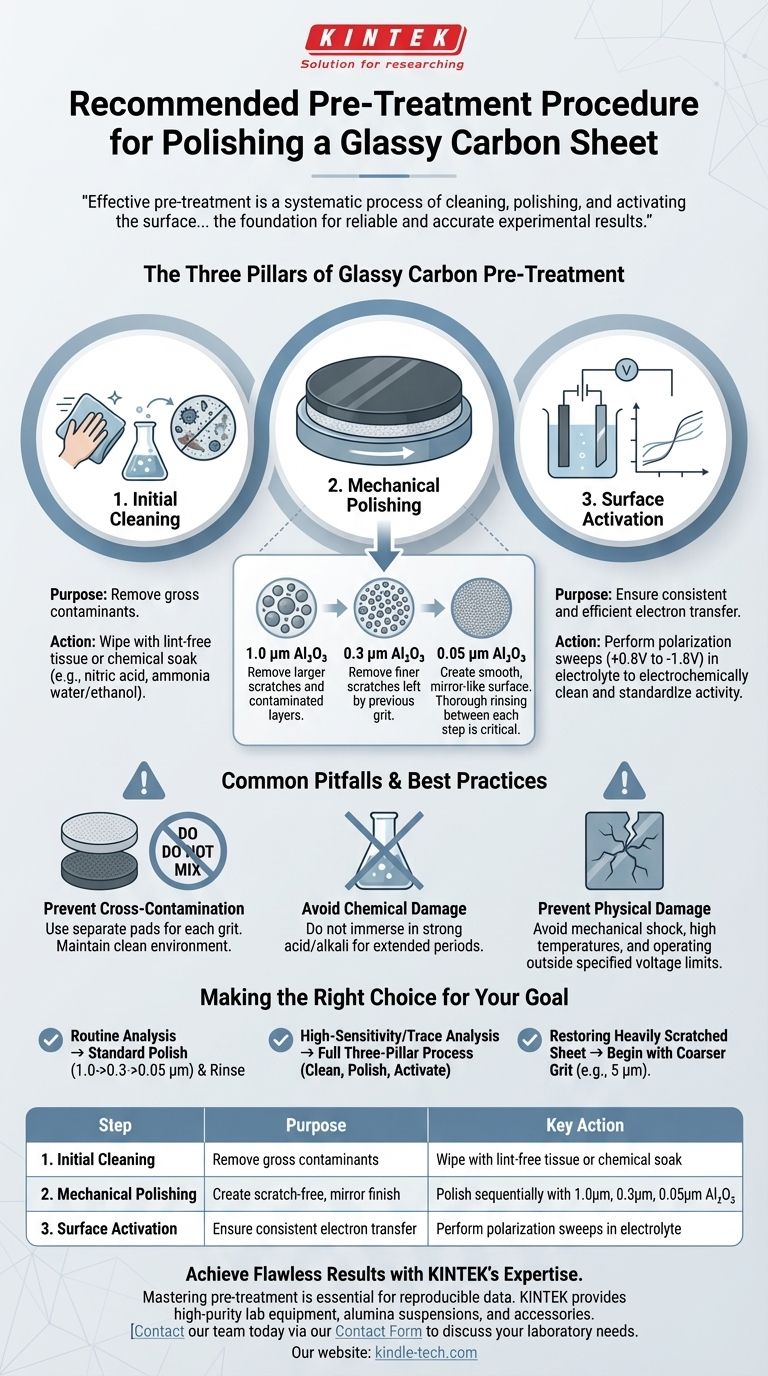

Effective pre-treatment is more than just polishing. It is a systematic process of cleaning, polishing, and activating the surface to remove contaminants and ensure a reproducibly active state, which is the foundation for reliable and accurate experimental results.

The Three Pillars of Glassy Carbon Pre-Treatment

Achieving a pristine glassy carbon surface is a three-stage process. Skipping a stage can introduce variability and compromise the quality of your data.

Step 1: Initial Cleaning

Before any polishing, the surface must be cleared of gross contaminants. Its smooth surface is easily fouled by organic substances and other impurities.

A simple wipe with a moist, lint-free lens tissue can remove dust and particulates. For more stubborn films, chemical cleaning by soaking in a solution like nitric acid or a mixture of ammonia water and ethanol can be effective.

Step 2: Mechanical Polishing

The core of the pre-treatment is mechanical polishing. This step physically removes a microscopic layer of the surface, eliminating scratches, embedded impurities, and inactive carbon sites.

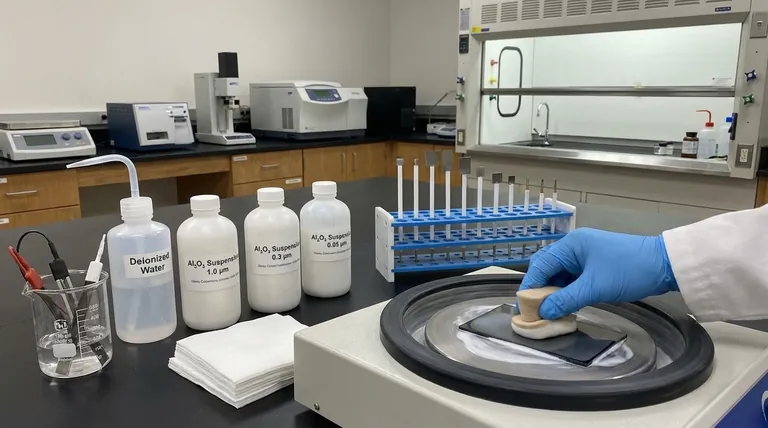

The standard procedure uses a sequence of alumina (Al₂O₃) slurries on a soft polishing pad, such as a chamois cloth.

- Coarse Polish (1.0 µm): Begin with a 1.0 µm alumina suspension to remove larger scratches and the bulk of any contaminated layers.

- Intermediate Polish (0.3 µm): After rinsing, move to a 0.3 µm suspension. This step removes the finer scratches left by the previous grit.

- Final Polish (0.05 µm): The final, critical step uses a 0.05 µm alumina suspension to create a smooth, mirror-like surface.

- Thorough Rinsing: After the final polish, the sheet must be meticulously rinsed with high-purity water (e.g., deionized or distilled) to remove all traces of the polishing medium.

A properly polished sheet will appear reflective and show no discernible scratches under good lighting.

Step 3: Surface Activation

For many applications, especially in electrochemistry, a polished surface must be electrochemically activated. This final step prepares the carbon surface to ensure consistent and efficient electron transfer.

Activation is typically done by performing repeated polarization sweeps within a specific voltage window (e.g., +0.8V to -1.8V) in a suitable electrolyte. This process electrochemically cleans the surface and standardizes its activity level.

Common Pitfalls and Best Practices

Proper care is essential for maintaining the integrity and performance of your glassy carbon sheet over time.

Preventing Cross-Contamination

Always use separate polishing pads for each grit size to avoid carrying over larger particles into a finer polishing step. Maintain a clean experimental environment to prevent contamination from organic substances and metal compounds in the air or on work surfaces.

Avoiding Chemical Damage

Do not immerse the sheet in strong acid or strong alkali solutions for extended periods. While glassy carbon is relatively inert, prolonged exposure can slowly degrade the surface.

Preventing Physical Damage

Glassy carbon is a brittle material. Avoid mechanical shock and contact with high-temperature sources that could cause thermal stress and cracking. When used as an electrode, always operate within the specified current and voltage limits to prevent irreversible damage to the surface.

Making the Right Choice for Your Goal

The required level of pre-treatment depends entirely on your application's sensitivity.

- If your primary focus is routine analysis: A standard mechanical polish (1.0 µm -> 0.3 µm -> 0.05 µm) followed by a thorough rinse is often sufficient.

- If your primary focus is high-sensitivity or trace analysis: The full three-pillar process, including chemical cleaning and electrochemical activation, is critical for achieving low background signals and high reproducibility.

- If you are restoring a heavily scratched sheet: Begin with an even coarser grit (e.g., 5 µm) before proceeding with the standard polishing sequence.

Mastering surface preparation is the single most important step toward achieving consistent and trustworthy results with glassy carbon.

Summary Table:

| Step | Purpose | Key Action |

|---|---|---|

| 1. Initial Cleaning | Remove gross contaminants | Wipe with lint-free tissue or chemical soak |

| 2. Mechanical Polishing | Create scratch-free, mirror finish | Polish sequentially with 1.0µm, 0.3µm, 0.05µm Al₂O₃ |

| 3. Surface Activation | Ensure consistent electron transfer | Perform polarization sweeps in electrolyte |

Achieve Flawless Results with KINTEK's Expertise

Mastering the pre-treatment of your glassy carbon sheets is essential for reproducible data in sensitive applications like electrochemistry and trace analysis. KINTEK specializes in providing the high-purity lab equipment and consumables—including reliable alumina polishing suspensions and accessories—that this precise procedure demands.

Let our experts help you optimize your surface preparation protocol. Contact our team today via our Contact Form to discuss your specific laboratory needs and ensure your glassy carbon performs flawlessly, batch after batch.

Visual Guide

Related Products

- Platinum Sheet Electrode for Laboratory and Industrial Applications

- Platinum Auxiliary Electrode for Laboratory Use

- Platinum Sheet Electrode for Battery Lab Applications

- Rubber Vulcanizer Vulcanizing Machine Plate Vulcanizing Press for Lab

- Isostatic Molding Pressing Molds for Lab

People Also Ask

- What is the expected lifespan of a platinum sheet electrode? Maximize Your Electrode's Service Life

- What precautions should be taken when using a platinum sheet electrode? Ensure Accurate & Reproducible Electrochemical Data

- How should a platinum sheet electrode be pretreated before use? Ensure Accurate Electrochemical Measurements

- What are the available specifications for platinum sheet electrodes? Find the Perfect Fit for Your Electrochemical Needs

- What is the most critical guideline for immersing a platinum sheet electrode in an electrolyte? Ensure Accurate Electrochemical Measurements