At its core, the significance of a freeze dryer in biotechnology is profound and simple: it is the premier technology for preserving the integrity of sensitive biological materials. Freeze dryers, through a process called lyophilization, remove water from samples like cells, enzymes, and vaccines without destroying their delicate structures, ensuring they remain viable and effective for long-term storage, research, and therapeutic use.

The central challenge in biotechnology is that biological materials are inherently unstable and degrade quickly. Freeze drying directly solves this by locking these materials in a state of suspended animation, preserving their original function and ensuring the reliability of experiments and the efficacy of products.

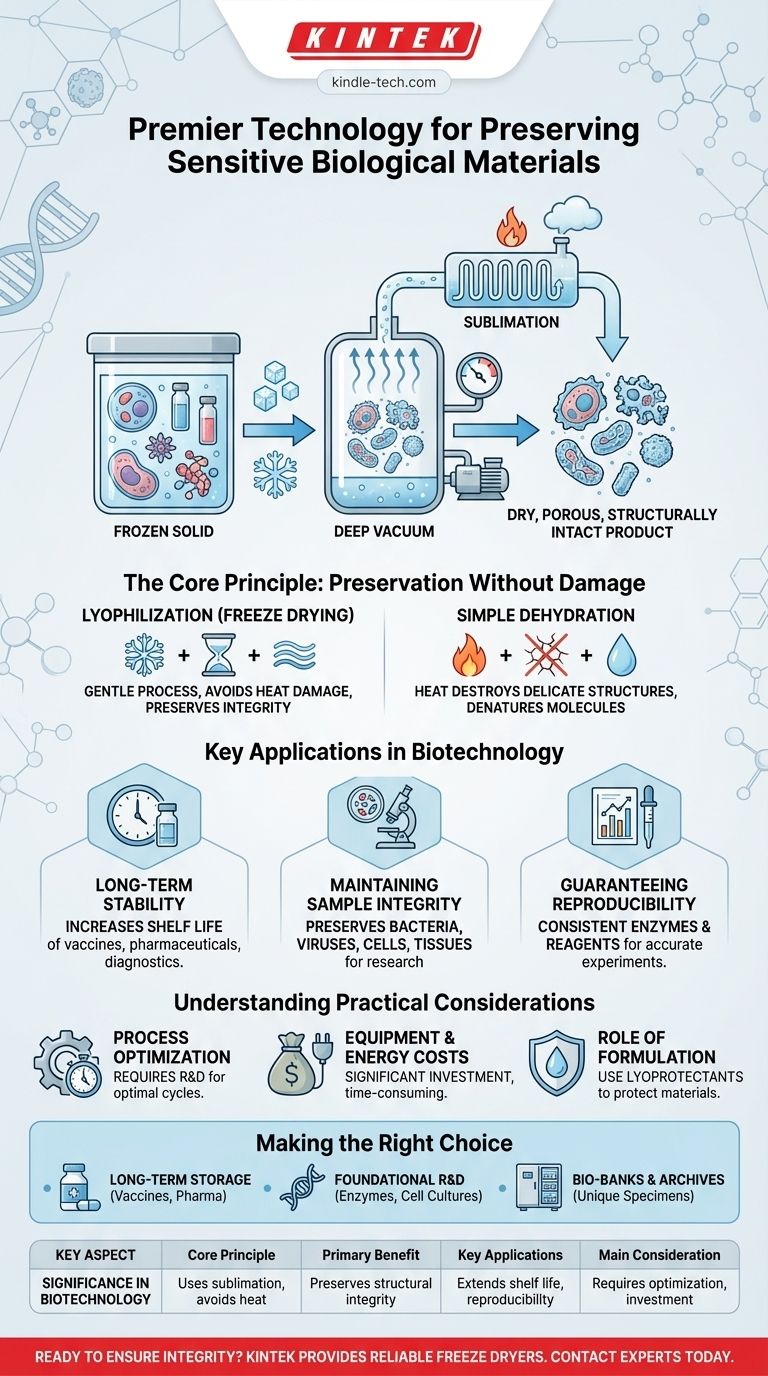

The Core Principle: Preservation Without Damage

Lyophilization is a fundamentally different approach to drying. Unlike simple dehydration, which uses heat that can destroy or "denature" complex molecules, freeze drying is a far more gentle process.

How Lyophilization Works

The process involves three main steps. First, the biological material is frozen solid. Next, it's placed under a deep vacuum. Finally, a small amount of heat is applied, causing the frozen water to turn directly into vapor, bypassing the liquid phase entirely. This physical process is known as sublimation.

Why This Protects Sensitive Materials

By avoiding liquid water and high temperatures, sublimation sidesteps the primary forces that damage biological structures. The result is a dry, porous, and structurally intact product that is lightweight and stable at room temperature. This preserves the chemical and structural composition of everything from complex proteins to entire cells.

Key Applications in Biotechnology

The ability to stabilize sensitive materials has made the freeze dryer an indispensable tool across the biotech landscape. Its impact is felt in research, diagnostics, and pharmaceutical development.

Ensuring Long-Term Stability and Shelf Life

The removal of water effectively halts most biological and chemical reactions that lead to degradation. This dramatically increases the shelf life of materials that would otherwise expire in days or weeks, making it essential for the commercial production of many vaccines, pharmaceuticals, and diagnostic kits.

Maintaining Sample Integrity for Research

Biotechnology research relies on consistent and reliable biological samples. Freeze drying allows laboratories to preserve cultures of bacteria, viruses, cells, and tissues for long-term analysis without worrying that their properties will change over time.

Guaranteeing Experimental Reproducibility

Scientific accuracy is built on the ability to reproduce experimental results. By stabilizing critical components like enzymes and other reagents, freeze dryers ensure that the tools used in experiments remain consistent. This allows for accurate comparisons of data generated months or even years apart.

Understanding the Practical Considerations

While powerful, freeze drying is a specialized process that requires careful planning and resources. It is not a one-size-fits-all solution.

Process Optimization is Critical

Every biological material responds differently to the stresses of freezing and drying. Developing a successful lyophilization cycle requires significant research and development to find the optimal temperatures, pressures, and timing to maximize viability and stability.

Equipment and Energy Costs

Freeze dryers are sophisticated pieces of equipment representing a significant capital investment. The process itself is also time-consuming and energy-intensive compared to simpler preservation methods, making it a choice reserved for high-value or highly sensitive materials.

The Role of Formulation

To protect materials from damage during the freezing and drying phases, scientists often add protective agents known as lyoprotectants. Developing the right formulation is a crucial step that adds another layer of complexity to the overall process.

Making the Right Choice for Your Goal

The decision to use a freeze dryer is directly tied to the need for uncompromising stability and integrity.

- If your primary focus is long-term storage of vaccines or pharmaceuticals: Freeze drying is the industry standard for creating a stable product that is easy to transport and has a multi-year shelf life.

- If your primary focus is foundational research and development: This technology is essential for creating consistent batches of enzymes, reagents, and cell cultures to ensure your experiments are accurate and reproducible.

- If your primary focus is creating bio-banks or sample archives: Lyophilization is a critical tool for preserving the integrity of tissues, bacteria, and other unique biological specimens for future study.

Ultimately, the freeze dryer is a cornerstone of modern biotechnology, providing the stability and reliability required for scientific discovery and medical advancement.

Summary Table:

| Key Aspect | Significance in Biotechnology |

|---|---|

| Core Principle | Uses lyophilization (freeze drying) to remove water via sublimation, avoiding heat damage. |

| Primary Benefit | Preserves the structural integrity and function of sensitive materials (cells, enzymes, vaccines). |

| Key Applications | Extends shelf life of pharmaceuticals, ensures experimental reproducibility, and enables bio-banking. |

| Main Consideration | Requires process optimization and represents a significant equipment investment. |

Ready to ensure the integrity of your sensitive biological samples?

KINTEK specializes in providing high-quality lab equipment and consumables, including reliable freeze dryers tailored for biotechnology applications. Our solutions help you preserve vaccines, enzymes, and cell cultures with precision, guaranteeing long-term stability and reproducible results for your research and development.

Contact our experts today to find the perfect freeze drying solution for your laboratory's needs and enhance your biotech workflows.

Visual Guide

Related Products

- Benchtop Laboratory Freeze Dryer for Lab Use

- Laboratory Sterilizer Lab Autoclave Herbal Powder Sterilization Machine for Plant

- Desktop Fast Laboratory Autoclave Sterilizer 35L 50L 90L for Lab Use

- Liquid Nitrogen Cryogenic Grinder Mill Cryomill Airflow Ultrafine Pulverizer

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

People Also Ask

- What are the overall benefits of freeze drying technology across industries? Achieve Unparalleled Product Preservation

- What are the key advantages of using freeze dryers? Achieve Unmatched Preservation for Your Materials

- What is the main difference between freeze drying and vacuum drying? A Guide to Quality vs. Efficiency

- What types of products are not suitable for freeze drying? Avoid These Common Freeze-Drying Failures

- What are the steps to use a laboratory freeze dryer? Master Lyophilization for Superior Sample Preservation