In engineering, sintering is a thermal process that transforms a powder into a solid, dense mass using heat. The key principle is that the material is heated to a high temperature that is below its melting point. This applied energy causes the individual particles of the powder to bond together, reducing the empty space between them and creating a coherent object.

Sintering is more than just solidification; it is a fundamental manufacturing tool for precisely engineering a material's internal structure—its microstructure. This control over properties like density, porosity, and grain size is what makes sintering indispensable for creating high-performance components that traditional melting and casting cannot achieve.

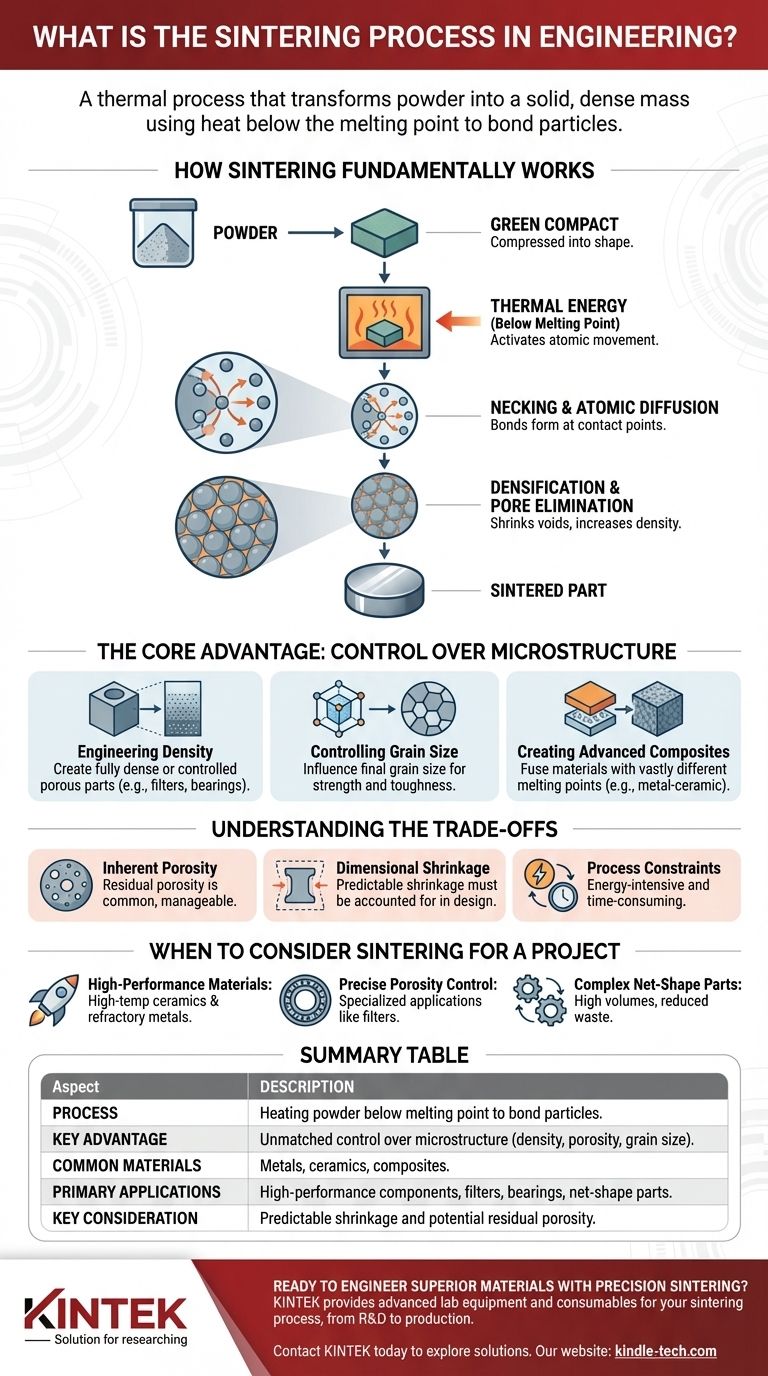

How Sintering Fundamentally Works

Sintering is a process driven by atomic-level mechanics. It reduces the surface energy of a collection of particles by replacing solid-gas interfaces with lower-energy solid-solid interfaces.

The Starting Point: A Powder Compact

The process begins with a fine powder of the desired material, such as a metal, ceramic, or composite. This powder is typically compressed into a desired shape, often called a "green compact" or "green body," which is fragile but holds its form.

The Role of Thermal Energy

When the green compact is heated in a furnace, the thermal energy activates atomic movement. Atoms are not static; this energy allows them to migrate and diffuse across the surfaces and boundaries of the powder particles.

Atomic Diffusion and "Necking"

The most critical stage is the formation of bonds, or "necks," at the contact points between adjacent particles. Atoms diffuse to these contact points, effectively building bridges that fuse the particles together.

Densification and Pore Elimination

As these necks grow, they pull the centers of the particles closer together. This action systematically shrinks the voids, or pores, that existed between the particles in the original compact. The result is a significant increase in the overall density and strength of the material.

The Core Advantage: Control Over Microstructure

The true power of sintering lies in its ability to dictate the final properties of a material by controlling its internal architecture. This is something that melting and casting, which create a uniform liquid that solidifies, cannot do with the same precision.

Engineering Desired Density

By carefully controlling the temperature, time, and atmosphere of the sintering process, engineers can stop the densification at a specific point. This allows for the creation of either fully dense, non-porous parts or components with a specific, controlled level of porosity for applications like filters or self-lubricating bearings.

Controlling Grain Size

The sintering conditions directly influence the final grain size of the material's crystal structure. Generally, smaller grain sizes result in higher strength and toughness. Sintering provides a lever to optimize this critical property for demanding applications.

Creating Advanced Composites

Sintering is exceptionally useful for creating composite materials from powders with vastly different melting points, such as metal-ceramic composites. These materials could not be combined by simply melting them together, but sintering allows them to be fused into a single, functional component.

Understanding the Trade-offs

While powerful, sintering is not a universal solution. It is critical to understand its inherent limitations to apply it effectively.

Inherent Porosity

Achieving 100% theoretical density is extremely difficult and often not economical. Most sintered parts contain a small amount of residual porosity, which can act as a potential point of mechanical failure if not managed.

Dimensional Shrinkage

The process of densification necessarily causes the part to shrink. This shrinkage must be precisely predicted and accounted for in the initial design of the green compact's mold to ensure the final part meets dimensional tolerances.

Process Constraints

Sintering can be an energy-intensive and time-consuming process. The initial cost of creating fine, high-quality powders and the capital expense for high-temperature furnaces must be justified by the performance requirements of the final component.

When to Consider Sintering for a Project

Your decision to use sintering should be driven by the specific performance goals of your component.

- If your primary focus is creating parts from high-performance ceramics or refractory metals: Sintering is often the only viable method, as these materials have melting points too high for conventional casting.

- If your primary focus is precise control over porosity and density: Sintering offers unmatched control for specialized applications like filters, self-lubricating bearings, or specific electronic components.

- If your primary focus is manufacturing complex, net-shape metal parts in high volumes: Powder metallurgy using sintering can be more cost-effective than machining, as it significantly reduces material waste and secondary processing.

Ultimately, sintering provides a powerful pathway to engineer a material's properties from the atomic level up, creating components optimized for performance.

Summary Table:

| Aspect | Description |

|---|---|

| Process | Heating powder below its melting point to bond particles into a solid mass. |

| Key Advantage | Unmatched control over material microstructure (density, porosity, grain size). |

| Common Materials | Metals, ceramics, and composites (e.g., metal-ceramic). |

| Primary Applications | High-performance components, filters, self-lubricating bearings, complex net-shape parts. |

| Key Consideration | Involves predictable shrinkage and potential for residual porosity. |

Ready to Engineer Superior Materials with Precision Sintering?

Sintering is the key to unlocking high-performance components with tailored properties that traditional methods can't achieve. KINTEK specializes in providing the advanced lab equipment and consumables necessary to perfect your sintering process, from R&D to production.

Whether you are working with advanced ceramics, refractory metals, or complex composites, our expertise can help you optimize for density, strength, and microstructure. Let's discuss how we can support your specific laboratory needs.

Contact KINTEK today to explore the right solutions for your project.

Visual Guide

Related Products

- Vacuum Heat Treat and Sintering Furnace with 9MPa Air Pressure

- Dental Porcelain Zirconia Sintering Ceramic Furnace Chairside with Transformer

- Spark Plasma Sintering Furnace SPS Furnace

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

People Also Ask

- How does a high-temperature vacuum sintering furnace facilitate the post-treatment of Zirconia coatings?

- What are the advantages of using a vacuum hot pressing furnace? Achieve 98.9% Density in Al2O3-TiC Laminated Ceramics

- What is the impact factor of powder metallurgy progress? A 2022 Analysis & Context

- What are the primary advantages of using a vacuum hot pressing sintering furnace? Maximize Density in B4C-CeB6 Ceramics

- What are the advantages of using a vacuum hot pressing sintering furnace? Superior Density for Nanocrystalline Fe3Al