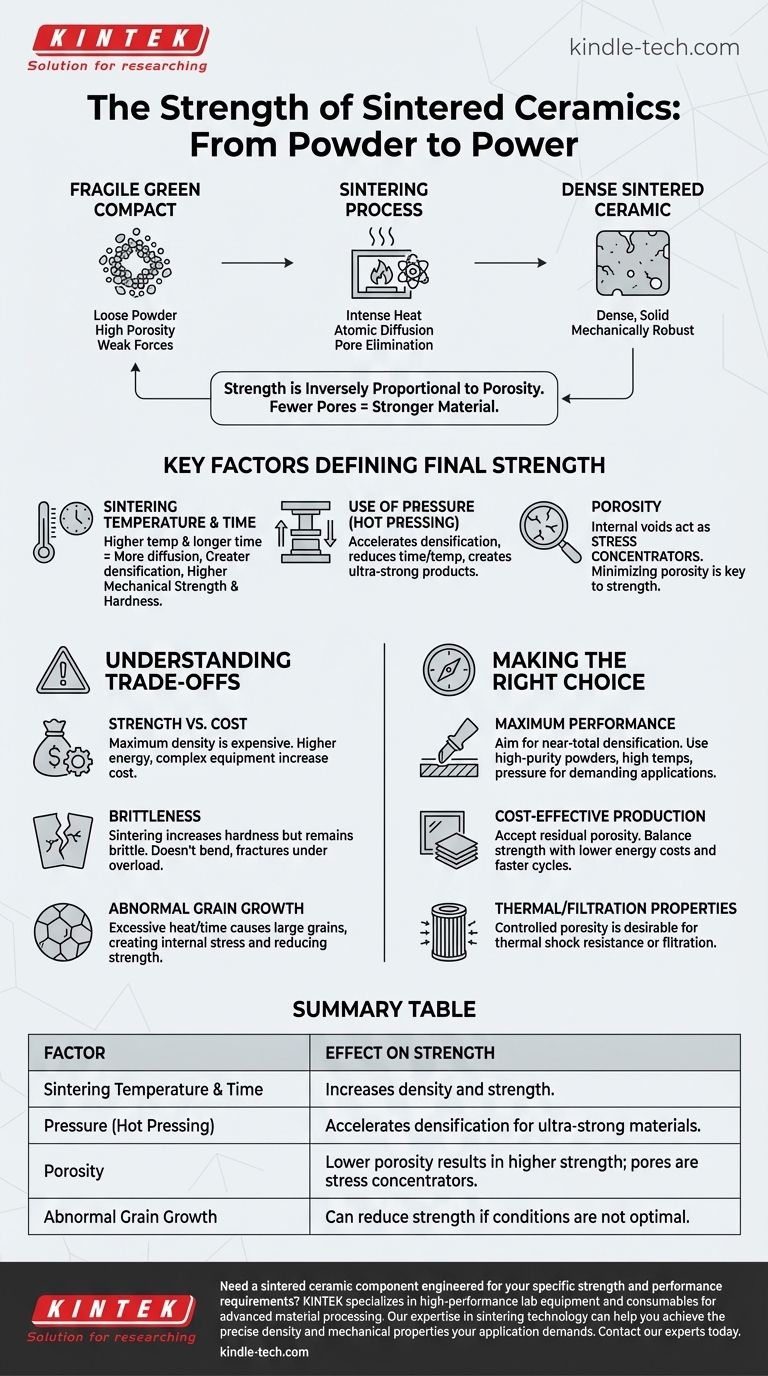

In short, sintering is the process that gives ceramics their exceptional strength. By heating a compacted powder to just below its melting point, individual particles fuse together, transforming a fragile object into a dense, solid, and mechanically robust material. This process dramatically reduces internal voids, which are the primary source of weakness in an unsintered ceramic.

The strength of a sintered ceramic is not a fixed value, but rather a direct outcome of its final density. The core principle is that strength is inversely proportional to porosity—the fewer internal pores, the stronger the material.

From Powder to Power: The Goal of Sintering

Sintering is a thermal treatment that converts a loose collection of particles, known as a "green compact," into a coherent, solid mass. The fundamental goal is to eliminate the empty spaces between these particles.

The "Green" State: A Fragile Beginning

Before sintering, ceramic powder is pressed into the desired shape. This object, called a green compact, is extremely fragile. It's held together only by weak mechanical forces between the particles, much like a sandcastle.

The Role of Heat and Atomic Diffusion

During sintering, intense heat provides the energy for atoms to move, or diffuse, across the boundaries of adjacent particles. This atomic movement closes the gaps (pores) between them, causing the particles to fuse and the entire object to shrink and densify.

The Enemy of Strength: Porosity

Pores are the single greatest weakness in a ceramic. These internal voids act as stress concentrators. When a force is applied, the stress multiplies at the edge of a pore, creating a microscopic crack that can propagate rapidly and cause the entire piece to fail. Sintering directly combats this by minimizing porosity.

Key Factors That Define Final Strength

The final strength of a sintered ceramic is not accidental; it is engineered by carefully controlling several key variables during the manufacturing process.

Sintering Temperature and Time

Higher temperatures and longer sintering times allow for more complete atomic diffusion. This results in greater densification, reduced porosity, and consequently, higher mechanical strength and hardness. Pure oxide ceramics often require very high temperatures as diffusion occurs entirely in the solid state.

The Use of Pressure

Applying external pressure during the heating process, a technique known as hot pressing, can dramatically accelerate densification. This method forces particles into closer contact, reducing the time and even the temperature required to achieve a highly dense, ultra-strong final product.

Understanding the Trade-offs

While sintering creates incredibly strong materials, the process involves critical trade-offs that every engineer and designer must consider.

Strength vs. Cost

Achieving maximum density and strength is expensive. Higher temperatures, longer furnace times, and the use of pressure-assisted sintering all consume significant energy and require more complex equipment, driving up the cost of the final component.

Brittleness: The Inherent Nature of Ceramics

Sintering massively increases a ceramic's hardness and compressive strength, but it does not change its fundamentally brittle nature. Unlike metals, sintered ceramics do not bend or deform under load; they fracture. High density reduces the likelihood of fracture, but it does not eliminate the risk.

The Risk of Abnormal Grain Growth

If sintering is performed at too high a temperature or for too long, the microscopic crystalline grains can grow excessively large. This condition, known as abnormal grain growth, can paradoxically create new internal stresses and reduce the material's overall strength and fracture toughness.

Making the Right Choice for Your Goal

The optimal sintering strategy depends entirely on the intended application and its specific performance requirements.

- If your primary focus is maximum mechanical performance: You must aim for near-total densification by using high-purity powders, high temperatures, and potentially pressure-assisted sintering to create materials for demanding applications like cutting tools or armor.

- If your primary focus is cost-effective mass production: You can accept a certain level of residual porosity for applications like ceramic tiles or sanitaryware, balancing acceptable strength with the need for lower energy costs and faster production cycles.

- If your primary focus is thermal insulation or filtering: Controlled porosity is actually desirable, intentionally trading maximum mechanical strength for enhanced thermal shock resistance or specific filtration properties.

By understanding these core principles, you can specify or design a sintered ceramic engineered precisely for its intended purpose.

Summary Table:

| Factor | Effect on Strength |

|---|---|

| Sintering Temperature & Time | Higher temperature and longer time increase density and strength. |

| Pressure (Hot Pressing) | Accelerates densification for ultra-strong materials. |

| Porosity | Lower porosity results in higher strength; pores act as stress concentrators. |

| Abnormal Grain Growth | Can reduce strength if sintering conditions are not optimal. |

Need a sintered ceramic component engineered for your specific strength and performance requirements? KINTEK specializes in high-performance lab equipment and consumables for advanced material processing. Our expertise in sintering technology can help you achieve the precise density and mechanical properties your application demands. Contact our experts today to discuss how we can support your laboratory's material science goals.

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Dental Porcelain Zirconia Sintering Ceramic Furnace Chairside with Transformer

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

People Also Ask

- What is the high temperature of a muffle furnace? From 1100°C to 1700°C+ for Your Lab Needs

- What is the working temperature of a muffle furnace? Achieve Precise Heat Control for Your Lab

- What do you use a muffle furnace for? Achieve Contamination-Free High-Temperature Processing

- What are the advantages and disadvantages of a muffle furnace? A Guide to Precision Heating

- What is the use of muffle furnace in laboratory? Essential for High-Temp Analysis & Materials Processing