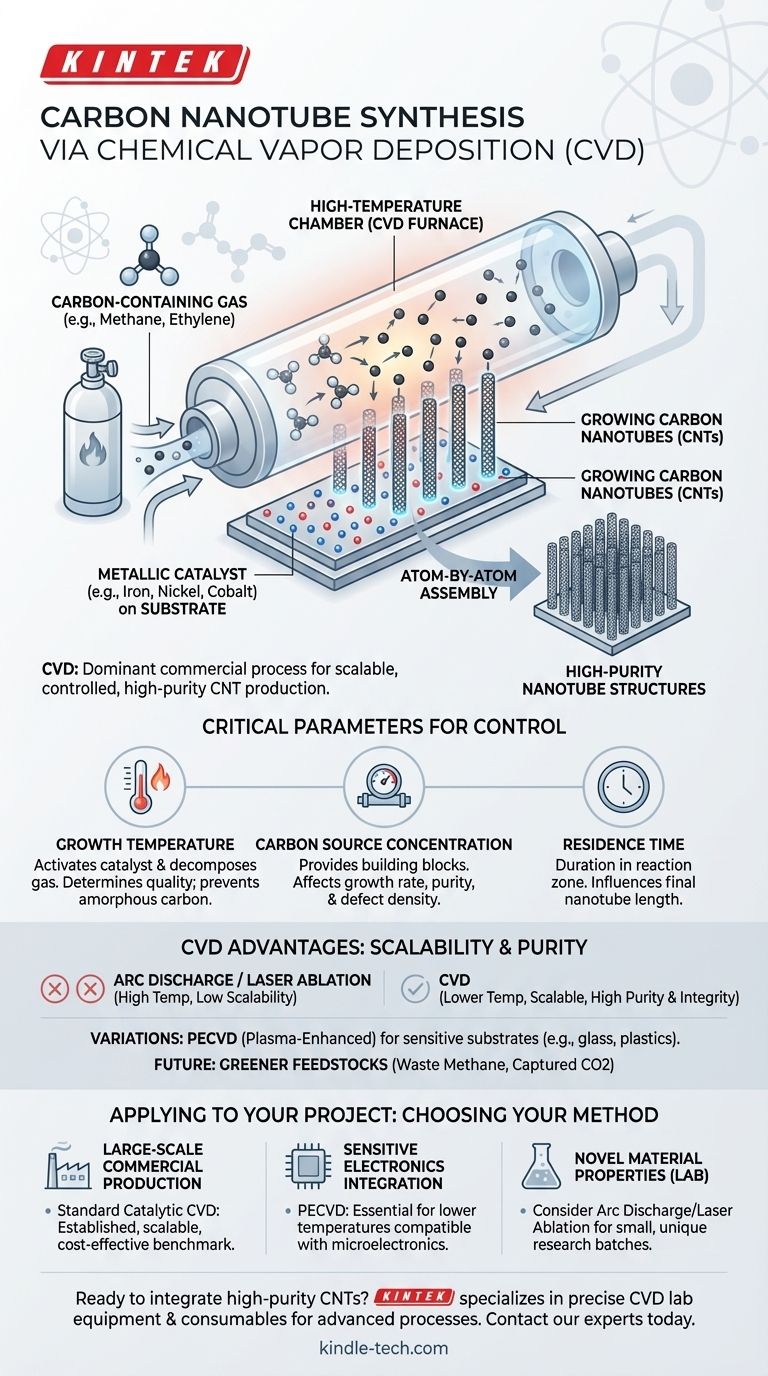

In short, the synthesis of carbon nanotubes via Chemical Vapor Deposition (CVD) is a process where a carbon-containing gas is introduced into a high-temperature chamber, causing it to decompose. With the help of a metallic catalyst, the carbon atoms reassemble on a substrate, growing into high-purity nanotube structures. This method has become the dominant commercial process due to its scalability and control.

While older methods like laser ablation and arc discharge exist, CVD is the industry standard for producing carbon nanotubes. Its value lies in using a catalyst to enable growth at lower temperatures, which provides the precise control needed for large-scale, high-quality production.

How CVD for Carbon Nanotubes Works

At its core, CVD is a bottom-up manufacturing process. It builds materials atom by atom from a gaseous state onto a solid surface, offering exceptional control over the final product's structure and purity.

The Fundamental Principle

The process involves flowing a precursor gas (the carbon source) over a prepared substrate inside a furnace. The high temperature provides the energy needed to break the chemical bonds in the gas, releasing carbon atoms.

The Critical Role of the Catalyst

For CNT synthesis, this process is almost always catalytic CVD. A thin layer of metal catalyst particles, such as iron, nickel, or cobalt, is deposited on the substrate first.

These catalyst nanoparticles serve two purposes. They dramatically lower the temperature required to break down the carbon gas, and they act as the "seed" or nucleation site from which the nanotube begins to grow.

The Carbon Source and Growth Environment

Common carbon sources are hydrocarbon gases like methane, ethylene, or acetylene. The entire reaction takes place within a controlled atmosphere, typically a quartz tube furnace heated to several hundred degrees Celsius.

The Critical Parameters You Must Control

The final quality, length, and diameter of the carbon nanotubes are not accidental. They are a direct result of carefully managing the key parameters of the CVD process.

Growth Temperature

Temperature is arguably the most critical factor. It directly influences the activity of the catalyst and the decomposition rate of the carbon gas. An incorrect temperature can lead to poor-quality growth or the formation of undesirable amorphous carbon instead of structured nanotubes.

Carbon Source Concentration

The concentration of the carbon-containing gas must be finely tuned. Too little gas results in slow or nonexistent growth, while too much can overwhelm the catalyst, leading to defects and lower purity.

Residence Time

This refers to the amount of time the precursor gas spends in the hot reaction zone. Residence time affects the length of the nanotubes; longer times generally produce longer tubes, but up to a point where catalyst deactivation or side reactions become an issue.

Understanding the Trade-offs: CVD vs. Other Methods

While CVD is the leading method, understanding its advantages in context is key to appreciating its role in nanotechnology.

The Advantage of Scalability and Purity

Traditional methods like arc discharge and laser ablation can produce very high-quality CNTs but operate at extremely high temperatures and are difficult to scale up for industrial production. CVD's ability to run at lower temperatures and in a continuous or large-batch format makes it the go-to commercial process.

Furthermore, CVD is valued for its ability to produce materials with greater purity and structural integrity compared to many other coating or synthesis techniques.

Variations for Specific Needs

Specialized versions of the process exist, such as Plasma-Enhanced Chemical Vapor Deposition (PECVD). PECVD uses an electric field to create plasma, which helps decompose the gas at even lower temperatures. This allows CNTs to be grown directly on sensitive substrates like glass or plastics.

The Future: Greener Feedstocks

Emerging research is focused on making the CVD process more sustainable. This includes using waste feedstocks like methane from pyrolysis or even capturing carbon dioxide via electrolysis and using it as the carbon source.

How to Apply This to Your Project

Your choice of synthesis method depends entirely on your end goal. Understanding the strengths of CVD and its variants allows you to align your approach with your technical requirements.

- If your primary focus is large-scale commercial production: Standard catalytic CVD is the established, scalable, and cost-effective industry benchmark.

- If your primary focus is integration with sensitive electronics: PECVD is the essential technology, as it enables CNT growth at lower temperatures compatible with microelectronics processing.

- If your primary focus is exploring novel material properties in a lab: While CVD is a strong candidate, arc discharge or laser ablation might be considered for creating small, unique batches for fundamental research.

Mastering the principles of CVD empowers you to precisely engineer carbon nanotube properties for the next generation of advanced materials and devices.

Summary Table:

| Parameter | Role in CVD Synthesis | Impact on CNTs |

|---|---|---|

| Growth Temperature | Activates catalyst & decomposes carbon gas | Determines quality, prevents amorphous carbon |

| Carbon Source Concentration | Provides building blocks for nanotube growth | Affects growth rate, purity, and defect density |

| Residence Time | Duration gas spends in the reaction zone | Influences the final length of the nanotubes |

| Catalyst (Fe, Ni, Co) | Lowers reaction temperature & acts as a seed | Controls nucleation site and growth initiation |

Ready to integrate high-purity carbon nanotubes into your research or production? KINTEK specializes in providing the precise lab equipment and consumables needed for advanced CVD processes. Our expertise ensures you have the right tools for scalable synthesis and controlled growth. Contact our experts today to discuss how we can support your laboratory's specific needs in nanotechnology and materials science.

Visual Guide

Related Products

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

People Also Ask

- What color diamonds are CVD? Understanding the Process from Brown Tint to Colorless Beauty

- What are the different types of thin films? A Guide to Optical, Electrical, and Functional Coatings

- What is the process of vacuum vapor deposition? Mastering CVD and PVD Thin-Film Coating

- What is PECVD in semiconductor? Enable Low-Temperature Thin Film Deposition for ICs

- How does PECVD work? Enable Low-Temperature, High-Quality Thin Film Deposition