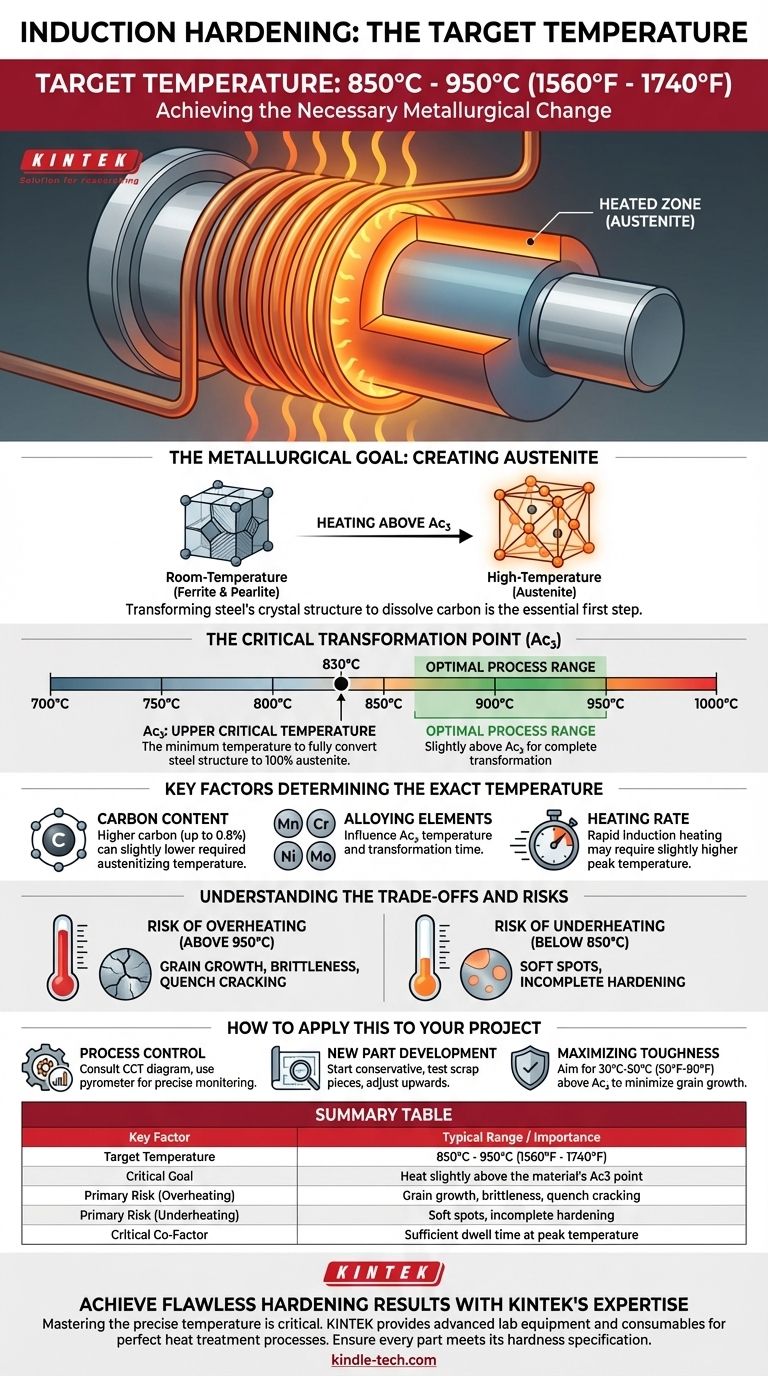

The target temperature for induction hardening is not a single value but a specific range, typically between 850°C and 950°C (1560°F to 1740°F) for common carbon and alloy steels. The exact temperature is critically dependent on the specific alloy's chemical composition. The goal is to heat the material just above its unique upper critical transformation temperature (Ac3) to achieve the necessary metallurgical change before quenching.

The core principle is not to simply reach a generic temperature, but to heat the steel just enough to transform its crystal structure into austenite. This precise temperature control is the key to achieving the desired surface hardness without compromising the integrity of the part.

The Metallurgical Goal: Creating Austenite

Induction hardening works by manipulating the crystal structure of steel. The temperature you use is simply the tool to achieve the required structural change at the surface of the component.

The Austenitizing Temperature

The primary goal of heating is to reach the austenitizing temperature. This is the point at which the steel's room-temperature structure (ferrite and pearlite) transforms into a new, high-temperature structure called austenite.

Austenite has a unique face-centered cubic crystal lattice that can dissolve a significant amount of carbon. This is the essential first step in the hardening process.

The Critical Transformation Point (Ac3)

Every steel alloy has a specific temperature known as its upper critical temperature, or Ac3. This is the minimum temperature required to fully convert the steel's structure into 100% austenite.

Therefore, the target temperature for induction hardening must always be set slightly above the Ac3 point of the specific material being treated. This ensures a complete and uniform transformation in the heated zone.

Typical Temperature Ranges

For the most commonly hardened materials—medium-carbon and low-alloy steels (like 1045, 4140, or 4340)—the Ac3 temperature dictates a process temperature generally between 850°C and 950°C (1560°F to 1740°F).

Heating below this range will result in incomplete hardening, while heating significantly above it introduces other risks.

Key Factors That Determine the Exact Temperature

The "850°C to 950°C" range is a guideline, not a rule. The precise temperature for your application is determined by the material's unique properties.

Carbon Content

The carbon content of the steel has a direct effect on its Ac3 temperature. As a general rule, higher carbon content (up to about 0.8%) can slightly lower the required austenitizing temperature.

Alloying Elements

Elements like manganese, chromium, nickel, and molybdenum all influence the transformation characteristics of steel. They can raise or lower the Ac3 temperature and, just as importantly, affect the time required at that temperature for the transformation to complete.

Heating Rate

Induction heating is exceptionally fast. This rapid heating rate means you may need to use a slightly higher peak temperature than you would in a slower furnace-heating process. This ensures that the core of the heated surface layer has enough time to fully transform into austenite before the quench begins.

Understanding the Trade-offs and Risks

Choosing the correct temperature is a balancing act. Deviating from the optimal point in either direction leads to process failure.

The Risk of Overheating

Heating the steel significantly above its Ac3 temperature causes the crystalline grains within the austenite to grow larger. Large grain structures become very brittle and are more susceptible to distortion or quench cracking when the part is rapidly cooled.

The Risk of Underheating

If you fail to reach a temperature above the Ac3 point, the transformation to austenite will be incomplete. This results in "soft spots" and a failure to achieve the specified hardness and wear resistance, defeating the purpose of the hardening process.

The Importance of Dwell Time

Temperature is not the only variable; dwell time, or how long the material is held at the peak temperature, is also critical. A dwell time that is too short will cause incomplete transformation, while a dwell time that is too long can lead to the same grain growth issues as overheating.

How to Apply This to Your Project

Your objective is to find the lowest possible temperature above the Ac3 point that reliably achieves full hardening for your specific part and process.

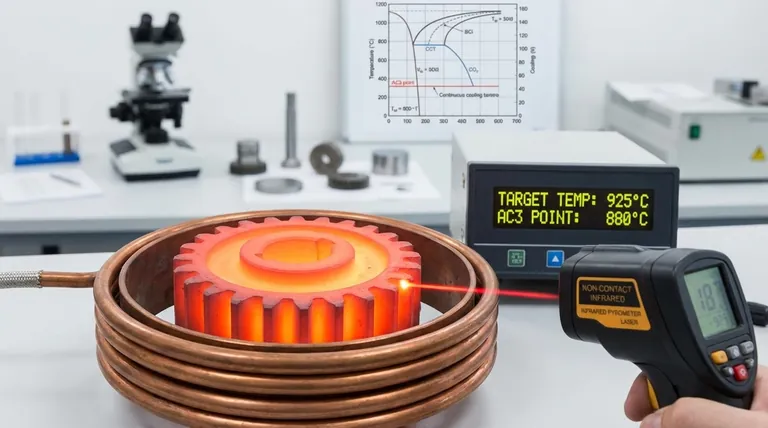

- If your primary focus is process control and repeatability: Consult the material's Continuous Cooling Transformation (CCT) diagram to identify the Ac3 temperature and use a non-contact pyrometer to precisely monitor the part's surface temperature during the cycle.

- If your primary focus is developing a process for a new part: Begin with a conservative estimate on the lower end of the material's expected range and run tests on scrap pieces. Analyze the resulting hardness and microstructure, adjusting the temperature upwards in small increments until the desired properties are achieved without signs of overheating.

- If your primary focus is maximizing toughness while ensuring hardness: Aim for a target temperature that is only about 30°C to 50°C (50°F to 90°F) above the material's Ac3 point. This minimizes grain growth and reduces the risk of brittleness.

Ultimately, temperature is the primary lever you use to control the final metallurgical properties of the component.

Summary Table:

| Key Factor | Typical Range / Importance |

|---|---|

| Target Temperature | 850°C - 950°C (1560°F - 1740°F) |

| Critical Goal | Heat slightly above the material's Ac3 point |

| Primary Risk (Overheating) | Grain growth, brittleness, quench cracking |

| Primary Risk (Underheating) | Soft spots, incomplete hardening |

| Critical Co-Factor | Sufficient dwell time at peak temperature |

Achieve Flawless Hardening Results with KINTEK's Expertise

Mastering the precise temperature for induction hardening is critical to your component's performance and longevity. The wrong temperature can lead to costly failures like soft spots or quench cracking.

At KINTEK, we specialize in providing the advanced lab equipment and consumables you need to develop, monitor, and perfect your heat treatment processes. Whether you are setting up a new production line or optimizing an existing one, our solutions help you achieve consistent, high-quality results.

Let us help you ensure every part meets its hardness specification.

Contact our experts today to discuss your specific application and how KINTEK can support your laboratory's success.

Visual Guide

Related Products

- Vacuum Heat Treat Furnace and Levitation Induction Melting Furnace

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

- Vertical Laboratory Tube Furnace

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- What are the four types of heat treating processes? Master Annealing, Normalizing, Hardening, and Tempering

- What is the process of vacuum quenching? Achieve Superior Hardness with a Pristine Surface Finish

- What are the three main heat treatments? Mastering Annealing, Hardening & Tempering

- What is the difference between annealing hardening and tempering? Master Metal Properties for Your Lab

- What are the parts of a vacuum furnace? A Guide to the 5 Core Systems