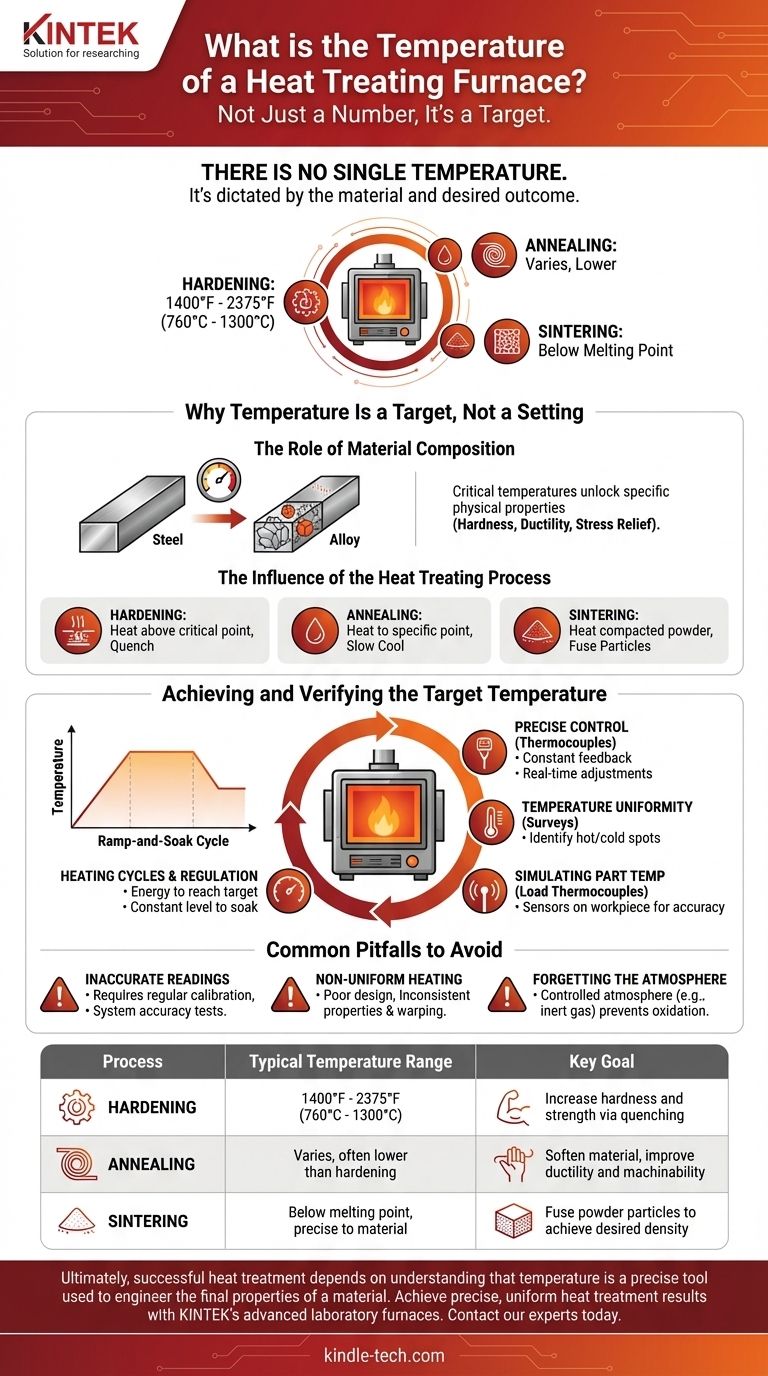

There is no single temperature for a heat treating furnace; the correct temperature is dictated entirely by the material and the desired outcome. For common steels, hardening processes can require temperatures ranging from 1400°F (760°C) to as high as 2375°F (1300°C). The temperature must be precisely controlled for the specific metallurgical transformation required by the process, whether it's hardening, annealing, or sintering.

A heat treating furnace's temperature is not a static number but a highly controlled variable in a dynamic process. The critical question isn't "what is the temperature," but rather "what temperature does my specific material require to achieve the desired properties?"

Why Temperature Is a Target, Not a Setting

The temperature inside a furnace is the primary tool used to intentionally alter a material's microstructure. Different temperatures unlock different physical properties, such as hardness, ductility, or internal stress relief.

The Role of Material Composition

Every metal alloy has critical temperatures at which its internal crystal structure transforms. For steel, this involves changing the iron's crystal phase to austenite, which allows carbon to dissolve before being locked in place by rapid cooling (quenching).

The exact temperature for this transformation depends on the steel's specific composition.

The Influence of the Heat Treating Process

The goal of the treatment determines the required temperature profile.

- Hardening requires heating the material above its critical transformation point before quenching.

- Annealing involves heating to a specific temperature and then cooling very slowly to soften the material and improve its machinability.

- Sintering heats compacted powder to a temperature high enough to fuse the particles but below the material's melting point to achieve a desired density.

Each of these processes uses a different temperature target to produce a unique result.

Achieving and Verifying the Target Temperature

Setting a temperature is simple, but ensuring the entire workpiece uniformly reaches and holds that temperature is a complex engineering challenge. This requires a sophisticated system of control and verification.

Heating Cycles and Regulation

A furnace requires a significant amount of energy to reach its target temperature. Once there, the heat input is reduced to a constant level to maintain, or "soak," the material at that temperature for a specified time.

This ramp-and-soak cycle is fundamental to ensuring the entire part is heated through.

The Importance of Precise Control

Furnaces use thermocouples as sensors to provide constant temperature feedback to a control system. This feedback loop allows the system to make real-time adjustments to the heating elements, ensuring the temperature remains stable and accurate.

Temperature Uniformity is Key

The temperature displayed on the controller is not necessarily the temperature everywhere inside the furnace. Temperature uniformity surveys are performed to identify the hottest and coldest spots within the working volume.

Inconsistent heating can cause a part to warp, crack, or have unreliable properties across its structure.

Simulating Part Temperature

The air temperature inside the furnace can be different from the actual temperature of the material being treated. For this reason, load thermocouples are often placed on or within the workpiece itself to provide the most accurate reading of the part's thermal state.

Common Pitfalls to Avoid

Achieving the correct temperature is critical, but several factors can compromise the process, leading to failed parts and wasted resources.

Inaccurate Temperature Readings

A furnace is only as accurate as its sensors. Regular system accuracy tests and thermocouple calibration are essential. Relying on an unverified reading can lead to treating a material at the wrong temperature, completely invalidating the process.

Non-Uniform Heating

Poor furnace design or improper part placement can lead to significant temperature variations. This is a primary cause of inconsistent hardness, internal stress, and dimensional distortion in finished components.

Forgetting the Atmosphere

Temperature is only one part of the equation. Many processes require a controlled atmosphere (such as an inert gas) to prevent oxidation and scaling on the material's surface at high temperatures.

Making the Right Choice for Your Goal

The correct temperature is always a function of your material and your objective.

- If your primary focus is hardening carbon steel: Your target temperature will be above the material's critical transformation point, typically in the 1400°F to 1600°F range, to prepare it for quenching.

- If your primary focus is annealing or stress-relieving: You will use carefully controlled temperatures, often lower than for hardening, to soften the material and improve ductility without fundamentally changing its phase.

- If your primary focus is sintering powdered metals: The temperature must be high enough to fuse particles but below the melting point, where precision is paramount for achieving the required final density.

Ultimately, successful heat treatment depends on understanding that temperature is a precise tool used to engineer the final properties of a material.

Summary Table:

| Process | Typical Temperature Range | Key Goal |

|---|---|---|

| Hardening | 1400°F - 2375°F (760°C - 1300°C) | Increase hardness and strength via quenching |

| Annealing | Varies, often lower than hardening | Soften material, improve ductility and machinability |

| Sintering | Below melting point, precise to material | Fuse powder particles to achieve desired density |

Achieve precise, uniform heat treatment results with KINTEK's advanced laboratory furnaces. Whether you are hardening steel, annealing metals, or sintering powders, our equipment delivers the exact temperature control and uniformity your process demands. Don't leave your material's properties to chance—contact our experts today to discuss how our lab equipment can enhance your heat treating outcomes and ensure consistent, high-quality results for your laboratory.

Visual Guide

Related Products

- Vertical Laboratory Tube Furnace

- Vacuum Heat Treat Furnace and Levitation Induction Melting Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

People Also Ask

- What is quartz tube heating? Achieve Instant, Targeted Heat with Infrared Radiation

- How do you clean a quartz tube furnace? Prevent Contamination & Extend Tube Lifespan

- How do you clean a tubular furnace tube? A Step-by-Step Guide to Safe and Effective Maintenance

- What is the standard thickness of plating? Optimize Durability, Corrosion & Cost

- What is the temperature of a quartz tube furnace? Master the Limits for Safe, High-Temp Operation