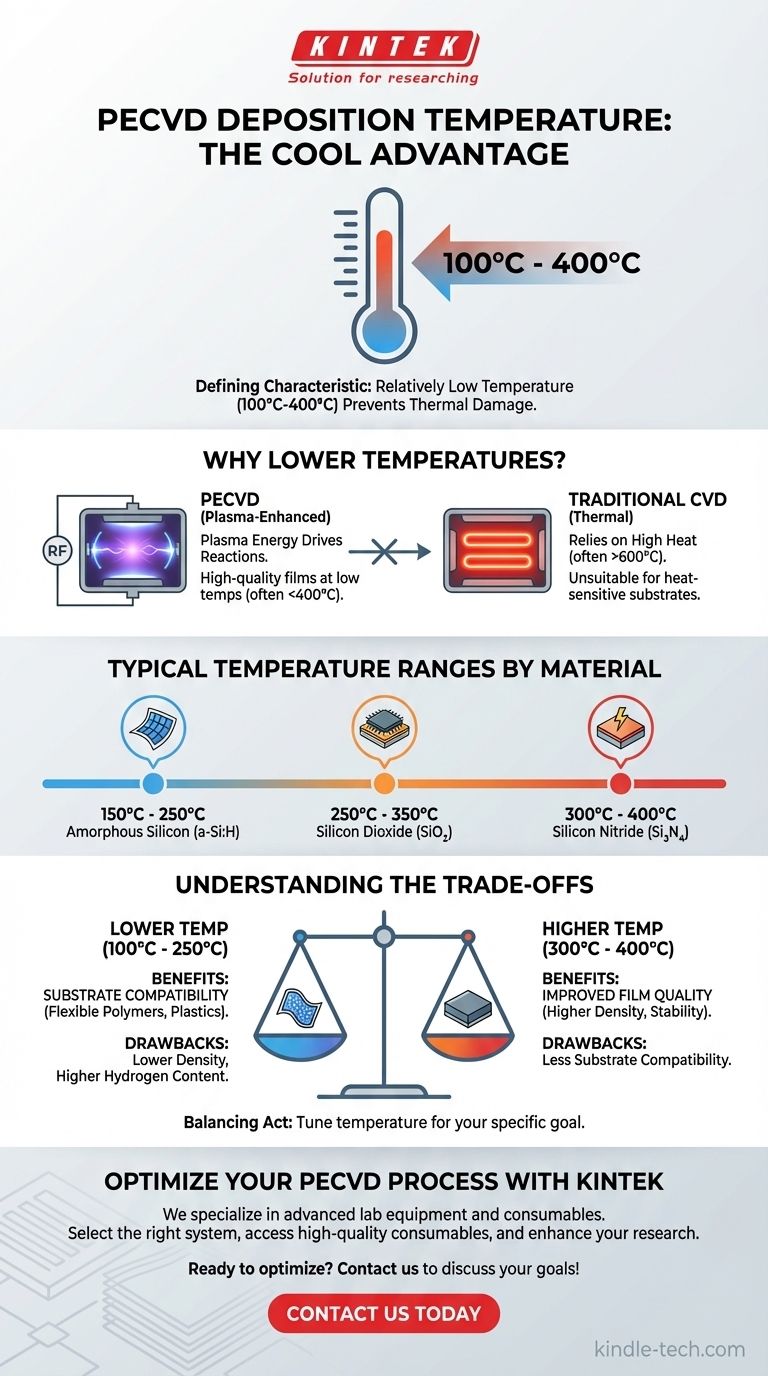

In short, the deposition temperature for Plasma-Enhanced Chemical Vapor Deposition (PECVD) is its defining characteristic, typically ranging from 100°C to 400°C. This relatively low temperature is the primary reason it is chosen over other deposition methods, as it allows for processing on a wide variety of materials without causing thermal damage.

The core advantage of PECVD is its use of plasma to energize precursor gases. This enables the deposition of high-quality thin films at significantly lower temperatures than traditional Chemical Vapor Deposition (CVD), which relies solely on high heat (often >600°C).

Why PECVD Operates at Lower Temperatures

To understand PECVD, it's essential to contrast it with its thermal counterpart. The fundamental difference lies in how the required reaction energy is supplied to the system.

The Role of Plasma Energy

In PECVD, an electromagnetic field (typically radio frequency) is used to ionize precursor gases, creating a plasma. This plasma is a highly energetic state of matter containing ions, radicals, and free electrons.

These highly reactive species in the plasma can then interact and deposit on the substrate surface to form a thin film. The energy needed to drive these chemical reactions comes from the plasma itself, not from high substrate heat.

The Contrast with Conventional CVD

Traditional thermal CVD processes have no plasma. They rely exclusively on high temperatures—often between 600°C and 1000°C—to provide enough thermal energy to break down the precursor gas molecules and initiate the deposition reaction.

This high-temperature requirement makes conventional CVD completely unsuitable for depositing films on substrates that cannot withstand such heat, such as plastics, polymers, or fully fabricated semiconductor devices with low-melting-point metals.

Typical Temperature Ranges by Material

While the overall range for PECVD is low, the exact temperature is a critical process parameter that is tuned to achieve the desired film properties for a specific material.

Silicon Nitride (Si₃N₄)

Silicon nitride is a workhorse film used for electrical insulation and as a protective passivation layer. It is most commonly deposited in the 300°C to 400°C range for microelectronics applications.

Silicon Dioxide (SiO₂)

Used as a dielectric insulator, SiO₂ is typically deposited at temperatures between 250°C and 350°C. Operating in this range provides a good balance of film quality and process speed.

Amorphous Silicon (a-Si:H)

Amorphous silicon, critical for thin-film solar cells and transistors, is often deposited at even lower temperatures, typically from 150°C to 250°C, to control its hydrogen content and electronic properties.

Understanding the Temperature Trade-offs

Choosing a deposition temperature is not arbitrary; it involves a series of critical engineering trade-offs between film quality, deposition rate, and substrate compatibility.

Benefits of Lower Temperature

The primary benefit is substrate compatibility. Temperatures below 200°C allow for deposition on flexible polymers and other temperature-sensitive materials that would be destroyed by other methods.

Drawbacks of Lower Temperature

Films deposited at the lower end of the PECVD range can have lower density and higher concentrations of incorporated hydrogen. This can negatively impact the film's electrical properties, optical clarity, or long-term stability.

Benefits of Higher Temperature

Pushing the temperature towards the upper end of the PECVD range (e.g., 400°C) generally improves film quality. It provides more surface energy for deposited atoms to arrange into a denser, more stable structure with fewer impurities, often resulting in lower film stress.

Making the Right Choice for Your Goal

The optimal PECVD temperature is not a single value but a parameter you must tune based on the specific goal of your application.

- If your primary focus is compatibility with sensitive substrates: Operate at the lowest possible temperature (e.g., 100°C - 250°C) that still yields an acceptable film for your needs.

- If your primary focus is achieving the highest film quality and density: Use the highest temperature your substrate can safely tolerate (e.g., 300°C - 400°C) to improve film stoichiometry and stability.

Ultimately, controlling temperature is the key to balancing film performance with substrate limitations in any PECVD application.

Summary Table:

| Material | Typical PECVD Temperature Range | Common Applications |

|---|---|---|

| Silicon Nitride (Si₃N₄) | 300°C - 400°C | Electrical insulation, passivation layers |

| Silicon Dioxide (SiO₂) | 250°C - 350°C | Dielectric insulation |

| Amorphous Silicon (a-Si:H) | 150°C - 250°C | Thin-film solar cells, transistors |

Ready to optimize your PECVD process for superior thin-film deposition?

At KINTEK, we specialize in providing advanced lab equipment and consumables tailored to your laboratory's unique needs. Whether you're working with temperature-sensitive polymers or require high-density films for electronics, our expertise ensures you achieve the perfect balance between film quality and substrate compatibility.

Let us help you:

- Select the right PECVD system for your temperature requirements

- Access high-quality consumables for consistent, reliable results

- Enhance your research or production with our specialized solutions

Contact us today via our form to discuss how KINTEK can support your thin-film deposition goals!

Visual Guide

Related Products

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

People Also Ask

- What is the process of PECVD in semiconductor? Enabling Low-Temperature Thin Film Deposition

- How are thin films deposited? A Guide to PVD vs. CVD Methods for Your Application

- What are the process capabilities of ICPCVD systems? Achieve Low-Damage Film Deposition at Ultra-Low Temperatures

- What are different types of thin films? A Guide to Function, Material, and Deposition Methods

- Why is a Matching Network Indispensable in RF-PECVD for Siloxane Films? Ensure Stable Plasma and Uniform Deposition