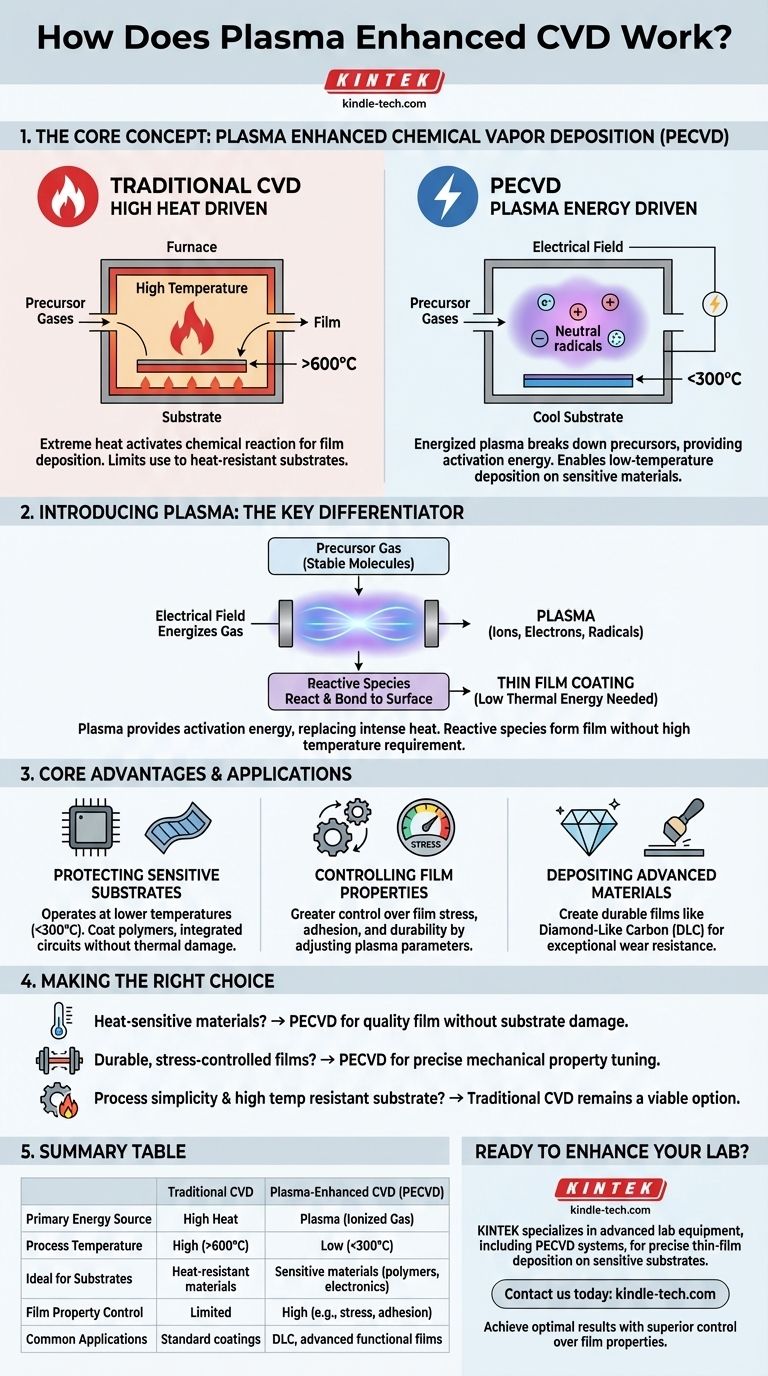

Plasma-Enhanced Chemical Vapor Deposition (PECVD) works by using an energized plasma to break down precursor gases instead of relying solely on high heat. This plasma—a state of matter containing ions, electrons, and neutral radicals—provides the energy needed for a chemical reaction to occur, allowing a thin film to deposit onto a substrate at much lower temperatures than in traditional Chemical Vapor Deposition (CVD).

The fundamental advantage of PECVD is its ability to deposit high-quality thin films at significantly reduced temperatures. This protects heat-sensitive substrates and enables the use of a wider range of materials that would be impossible with high-heat methods.

The Foundation: Traditional CVD

The Conventional Process

Standard Chemical Vapor Deposition (CVD) is a thermal process. A substrate is placed in a reaction chamber where volatile precursor gases are introduced.

The chamber and substrate are then heated to very high temperatures. This thermal energy activates a chemical reaction, causing the gases to decompose and deposit a solid thin film onto the substrate's surface.

The Limitation of Heat

The critical component in traditional CVD is extreme heat. It serves as the catalyst for the entire reaction.

This requirement limits the process to substrates that can withstand high temperatures, ruling out many plastics, electronics, and other sensitive materials.

Introducing Plasma: The Key Differentiator

What is Plasma?

In PECVD, the process starts similarly but introduces an electrical field to the chamber. This field energizes the precursor gas, transforming it into a plasma.

Plasma is an ionized gas, a mixture of highly energetic electrons, ions, and reactive neutral species called radicals.

How Plasma Replaces Extreme Heat

This energetic plasma provides the activation energy for the chemical reaction, a role normally filled by intense heat.

The reactive species within the plasma are primed to react and bond to the substrate surface without needing high thermal energy. This is the core mechanism that allows for a low-temperature deposition process.

Driving the Deposition

The plasma effectively breaks down the stable precursor molecules into the reactive components needed for film growth.

These components are then drawn to the workpiece's surface inside the vacuum chamber, where they condense and form the desired thin-film coating.

Core Advantages and Applications

Protecting Sensitive Substrates

The most significant benefit of PECVD is its ability to operate at lower temperatures. This makes it possible to coat materials like polymers, integrated circuits, and other temperature-sensitive components without causing thermal damage.

Controlling Film Properties

The use of plasma offers greater control over the properties of the deposited film. By adjusting plasma parameters, engineers can carefully manage factors like internal stress.

This control is crucial for optimizing the mechanical and functional properties of the coating, such as its adhesion and durability.

Depositing Advanced Materials

PECVD is commonly used to deposit highly durable films like diamond-like carbon (DLC). These coatings provide exceptional wear resistance for mechanical parts and tools.

The process enables the creation of materials and hybrid layers that would be difficult or impossible to form using purely thermal methods.

Making the Right Choice for Your Goal

By understanding the role of plasma, you can select the right deposition method for your specific technical requirements.

- If your primary focus is coating heat-sensitive materials: PECVD is the necessary choice to prevent substrate damage while achieving a high-quality film.

- If your primary focus is creating highly durable, stress-controlled films: PECVD provides the process control required to fine-tune the coating's mechanical properties for demanding applications.

- If your primary focus is process simplicity and the substrate can withstand high temperatures: Traditional thermal CVD remains a viable and often more straightforward option.

Ultimately, PECVD empowers engineers to move beyond the limitations of heat, opening up new possibilities in materials science and manufacturing.

Summary Table:

| Feature | Traditional CVD | Plasma-Enhanced CVD (PECVD) |

|---|---|---|

| Primary Energy Source | High Heat | Plasma (Ionized Gas) |

| Process Temperature | High (often >600°C) | Low (can be <300°C) |

| Ideal for Substrates | Heat-resistant materials | Sensitive materials (polymers, electronics) |

| Film Property Control | Limited | High (e.g., stress, adhesion) |

| Common Applications | Standard coatings | DLC, advanced functional films |

Ready to enhance your lab's capabilities with precise thin-film deposition?

KINTEK specializes in advanced lab equipment, including PECVD systems, to help you deposit high-quality coatings on even the most sensitive substrates. Whether you're working with polymers, integrated circuits, or developing durable diamond-like carbon (DLC) films, our expertise ensures you achieve optimal results with superior control over film properties.

Contact us today to discuss how our PECVD solutions can meet your specific research or production needs!

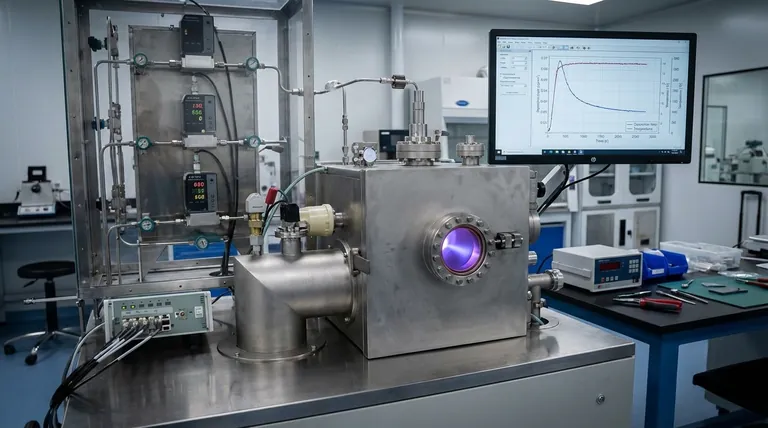

Visual Guide

Related Products

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Multi Heating Zones CVD Tube Furnace Machine Chemical Vapor Deposition Chamber System Equipment

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

People Also Ask

- What is plasma assisted deposition techniques? Unlock Superior Thin Film Engineering

- Can you put DLC on aluminum? Yes, with the right multi-layer coating process.

- How strong is DLC coating? Discover the Ultimate Shield for Wear and Friction

- How are wafers and electrodes configured within a PECVD system? Mastering Parallel-Plate Architecture

- What are the properties of silicon dioxide film deposited by PECVD at low temperature pressure? Achieve Superior Insulation on Sensitive Substrates

- What temperature does plasma deposition occur? Master Low-Temp Film Deposition for Sensitive Materials

- How does plasma deposition work? Enable Low-Temperature Thin Film Coating for Sensitive Materials

- What is the plasma source? A Guide to Generating and Controlling Ionized Gas for Industrial Applications