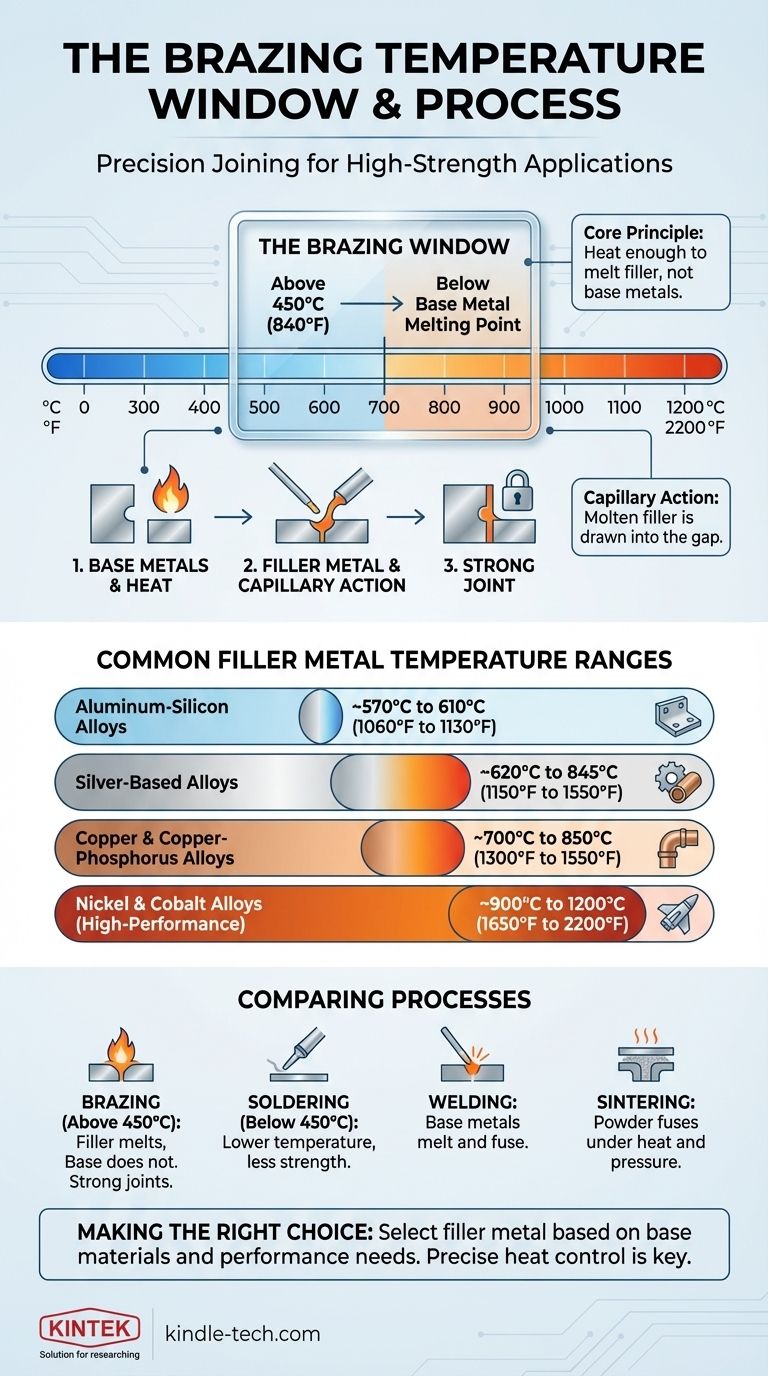

By definition, brazing is a metal-joining process that takes place at temperatures above 450°C (840°F). However, the exact temperature used is always below the melting point of the base metals being joined and is determined entirely by the specific filler metal alloy required for the application.

The core principle of brazing is not about a single temperature, but a specific temperature window: it must be hot enough to melt a filler metal but not so hot that it melts the parts you are joining.

The Defining Principle of Brazing Temperature

Brazing creates strong, permanent joints between two or more metal parts without melting the parts themselves. The temperature is the single most critical variable that enables this process.

Capillary Action is Key

The goal of brazing is to heat the base metals to a temperature where a specialized filler metal will melt when it comes into contact with them.

This molten filler is then drawn into the tight-fitting gap between the parts through a phenomenon called capillary action, creating the joint upon cooling.

Above 450°C (840°F): The Official Threshold

The American Welding Society (AWS) formally defines brazing as any process that occurs above 450°C (840°F).

This specific temperature is what distinguishes brazing from its lower-temperature counterpart, soldering.

Below the Base Metal's Melting Point (Solidus)

Crucially, the brazing temperature must remain below the solidus (the point at which a metal begins to melt) of the base metals.

If the base metals melt, the process is no longer brazing; it becomes welding. Maintaining this distinction is fundamental to a successful braze.

Common Brazing Temperature Ranges by Filler Metal

The practical brazing temperature is dictated by the chemical composition of the filler metal you use. Different base metals and applications require different fillers.

Aluminum-Silicon Alloys

These fillers are used for brazing aluminum components. They have a relatively low melting point to avoid melting the aluminum base metal.

The typical brazing temperature range for these alloys is ~570°C to 610°C (1060°F to 1130°F).

Silver-Based Alloys

Often called "silver solder" (a misnomer) or "hard solder," these are some of the most versatile and widely used brazing alloys for joining steel, stainless steel, copper, and brass.

Their brazing temperatures typically range from ~620°C to 845°C (1150°F to 1550°F).

Copper and Copper-Phosphorus Alloys

Copper-phosphorus alloys are excellent for joining copper to copper without needing a flux, as the phosphorus acts as a fluxing agent.

These alloys operate in a range of ~700°C to 850°C (1300°F to 1550°F).

Nickel and Cobalt Alloys

Used for high-performance applications like aerospace components or gas turbines, these fillers provide exceptional strength and resistance to high temperatures and corrosion.

These advanced alloys require much higher brazing temperatures, often from ~900°C up to 1200°C (1650°F to 2200°F).

Understanding Brazing vs. Other Processes

Confusion often arises between different high-temperature material processes. The distinction always comes down to temperature and intent.

Brazing vs. Soldering

The difference is simple: soldering occurs below 450°C (840°F), while brazing occurs above it. This results in brazed joints having significantly higher strength and temperature resistance than soldered joints.

Brazing vs. Welding

In brazing, only the filler metal melts. In welding, the edges of the base metals are melted and fused together, often with the addition of a filler metal.

Brazing vs. Sintering

Sintering is a process used to create a solid mass of material from a powder by applying heat and pressure. The temperature is high enough to cause the particles to fuse and bond, but typically below the full melting point.

While some high-temperature brazing (e.g., with nickel alloys) may operate in a similar temperature range as sintering (~750-1300°C), their goals are fundamentally different. Brazing joins distinct parts, while sintering forms a single part from powder.

Making the Right Choice for Your Project

Selecting the correct brazing temperature is a direct function of choosing the right filler metal for your base materials and performance requirements.

- If your primary focus is joining standard materials like copper or steel: Start by looking at silver or copper-based filler alloys, which operate in the 620-850°C range.

- If your primary focus is joining aluminum: You must use a lower-temperature aluminum-silicon filler, typically around 570-610°C, to avoid melting the parent material.

- If your primary focus is high-performance or high-temperature applications: You will need specialized nickel or cobalt-based fillers that require temperatures exceeding 900°C and controlled furnace atmospheres.

Ultimately, the right temperature is the one that properly melts your chosen filler metal without compromising the integrity of the parts you intend to join.

Summary Table:

| Filler Metal Type | Common Base Metals | Typical Brazing Temperature Range |

|---|---|---|

| Aluminum-Silicon Alloys | Aluminum | 570°C to 610°C (1060°F to 1130°F) |

| Silver-Based Alloys | Steel, Stainless Steel, Copper, Brass | 620°C to 845°C (1150°F to 1550°F) |

| Copper-Phosphorus Alloys | Copper to Copper | 700°C to 850°C (1300°F to 1550°F) |

| Nickel & Cobalt Alloys | High-Performance (Aerospace, Turbines) | 900°C to 1200°C (1650°F to 2200°F) |

Need precise, reliable heat for your brazing applications? KINTEK specializes in high-performance lab furnaces and thermal processing equipment, delivering the exact temperature control and uniform heating required for perfect brazed joints in materials from aluminum to advanced alloys. Let our experts help you select the ideal furnace for your specific filler metals and application requirements. Contact KINTALK today to discuss your brazing furnace needs!

Visual Guide

Related Products

- Vacuum Heat Treat Sintering Brazing Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Laboratory High Pressure Vacuum Tube Furnace

- Ultra-High Temperature Graphite Vacuum Graphitization Furnace

- 1700℃ Controlled Atmosphere Furnace Nitrogen Inert Atmosphere Furnace

People Also Ask

- What is the basic of brazing? A Guide to Strong, Low-Heat Metal Joining

- Which element made stainless steel difficult to brazed? It's Chromium's Oxide Layer

- Does brazing require heat? Yes, it's the catalyst for creating strong, permanent bonds.

- Can you braze two different metals? Yes, and here’s how to do it successfully.

- Why would you braze instead of weld? Preserve Material Integrity and Join Dissimilar Metals