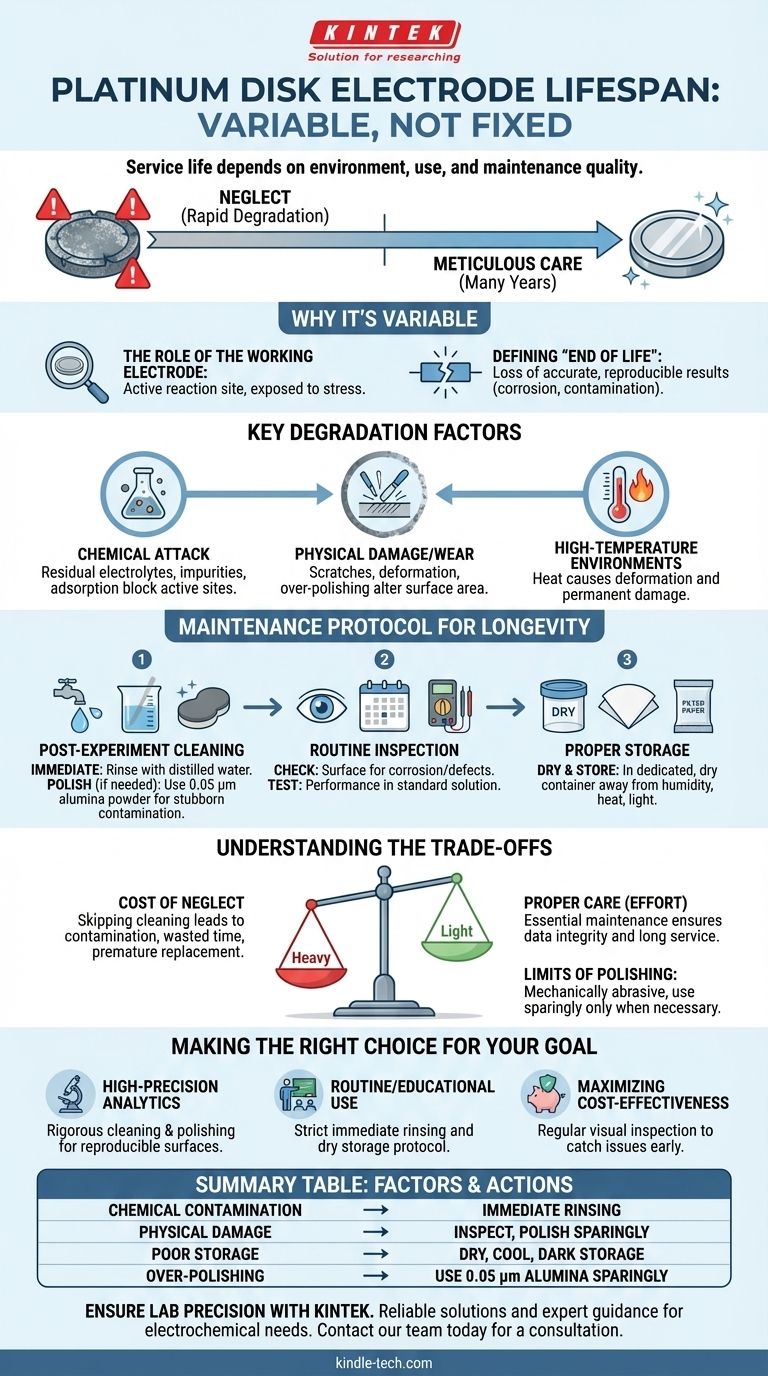

The lifespan of a platinum disk electrode is not a fixed timeframe. Instead of degrading over a set number of years, its service life is almost entirely dependent on its environment, the intensity of its use, and—most importantly—the quality of its maintenance. With meticulous care, a platinum electrode can last for many years; with neglect, its performance can degrade rapidly.

The central takeaway is that you, the user, have direct control over the electrode's lifespan. Its longevity is not a passive property but an active outcome of a disciplined maintenance protocol focused on cleaning, inspection, and proper storage.

Why Electrode Lifespan is Variable, Not Fixed

Unlike a consumable with a predictable expiration date, a platinum electrode is a precision instrument. Its "end of life" is determined by a loss of performance, which is caused by specific, preventable factors.

The Role of the Working Electrode

A platinum disk is typically used as the working electrode (WE). This means it is the active site where the electrochemical reaction of interest occurs. This function inherently exposes it to chemical and physical stress.

Defining "End of Life"

An electrode is considered at the end of its useful life when it can no longer produce accurate and reproducible results. This failure can manifest as physical corrosion, irreversible surface contamination, or significant wear that changes its electrochemical properties.

Key Factors That Degrade a Platinum Electrode

Understanding the primary causes of degradation is the first step toward preventing them. Performance decline is almost always traced back to one of three areas.

Chemical Attack and Contamination

Residual electrolytes, impurities from your sample, or adsorption of molecules onto the platinum surface can foul the electrode. This contamination blocks active sites, leading to inaccurate readings and sluggish performance.

Physical Damage and Wear

Scratches, deformation, or excessive wear from over-polishing can alter the electrode's defined surface area and electrochemical behavior. A compromised surface leads to unreliable and non-reproducible data.

High-Temperature Environments

Exposing the electrode to excessively high temperatures can cause it to deform or become permanently damaged. Platinum electrodes should not be used or stored in high-heat conditions.

The Maintenance Protocol for Maximum Longevity

A strict and consistent maintenance routine is the single most effective way to ensure a long service life for your electrode.

Post-Experiment Cleaning is Non-Negotiable

Immediately after use, remove the electrode from the electrolyte. Rinse it thoroughly with distilled water to remove all residue.

For stubborn contamination, you can polish the surface using 0.05 µm alumina powder on a polishing pad. This gentle abrasive action restores a clean, reactive surface.

Routine Inspection

Periodically inspect the electrode's surface for any signs of corrosion, discoloration, or physical deformation. You should also check its performance in a standard solution to ensure its potential and current response remain normal.

Proper Storage Conditions

After cleaning, gently dry the electrode with filter paper. Store it in a dedicated, dry container away from humidity, high temperatures, and strong light to prevent environmental degradation.

Understanding the Trade-offs

Proper care requires effort, but the alternatives are far more costly in terms of both time and money.

The Cost of Neglect

Skipping the post-experiment cleaning routine may save a few minutes, but it allows contaminants to adhere to the platinum surface. This leads to hours of wasted time troubleshooting flawed experiments and, ultimately, the premature and expensive replacement of the electrode.

The Limits of Polishing

While polishing is an essential maintenance step, it is a mechanically abrasive process. Each polish removes a microscopic layer of platinum. Over-polishing can eventually wear down the disk, so it should be used only when necessary to remove stubborn contamination, not as a routine cleaning step after every use.

Making the Right Choice for Your Goal

Your maintenance strategy should align with your experimental needs to ensure both longevity and data integrity.

- If your primary focus is high-precision analytics: Rigorous, consistent polishing and electrochemical cleaning are vital for ensuring the highly reproducible surface required for sensitive measurements.

- If your primary focus is routine or educational use: The most impactful habit is establishing a strict protocol for immediate rinsing and proper dry storage after every single use.

- If your primary focus is maximizing cost-effectiveness: Regular visual inspection is your best tool for catching potential issues like corrosion or fouling before they cause irreversible damage and require a replacement.

Ultimately, the lifespan of your platinum electrode is a direct reflection of the care you invest in it.

Summary Table:

| Factor | Impact on Lifespan | Key Maintenance Action |

|---|---|---|

| Chemical Contamination | Fouling leads to inaccurate results | Immediate post-use rinsing with distilled water |

| Physical Damage/Wear | Alters surface area and behavior | Inspect routinely; polish only when necessary |

| Poor Storage | Environmental degradation | Store dry, away from heat, humidity, and light |

| Over-Polishing | Gradual wear of the platinum disk | Use 0.05 µm alumina powder sparingly |

Ensure your lab's precision and maximize your investment in platinum electrodes.

KINTEK specializes in high-quality lab equipment and consumables, providing reliable solutions for all your electrochemical needs. Our experts can help you select the right electrodes and establish best-practice maintenance protocols to protect your instruments and ensure data integrity.

Contact our team today for a consultation and discover how KINTEK supports laboratory excellence.

Visual Guide

Related Products

- Platinum Sheet Electrode for Laboratory and Industrial Applications

- Rotating Platinum Disk Electrode for Electrochemical Applications

- Platinum Auxiliary Electrode for Laboratory Use

- Metal Disc Electrode Electrochemical Electrode

- Gold Disc Electrode

People Also Ask

- What are the available specifications for platinum sheet electrodes? Find the Perfect Fit for Your Electrochemical Needs

- What are the key performance characteristics and applications of platinum sheets? Unmatched Reliability for Demanding Applications

- How should a platinum sheet electrode be pretreated before use? Ensure Accurate Electrochemical Measurements

- What is the most critical guideline for immersing a platinum sheet electrode in an electrolyte? Ensure Accurate Electrochemical Measurements

- What are the specifications of the Platinum-Titanium Functional Electrode? Maximize Electrochemical Performance