In essence, Cold Isostatic Pressing (CIP) is a manufacturing process used to compact powdered materials into a solid, uniform mass at or near room temperature. It is primarily used for creating "green" parts—unfired components—from advanced ceramics, refractory materials, metals, and plastics. The key benefit is achieving highly consistent density throughout the part, regardless of its shape or size.

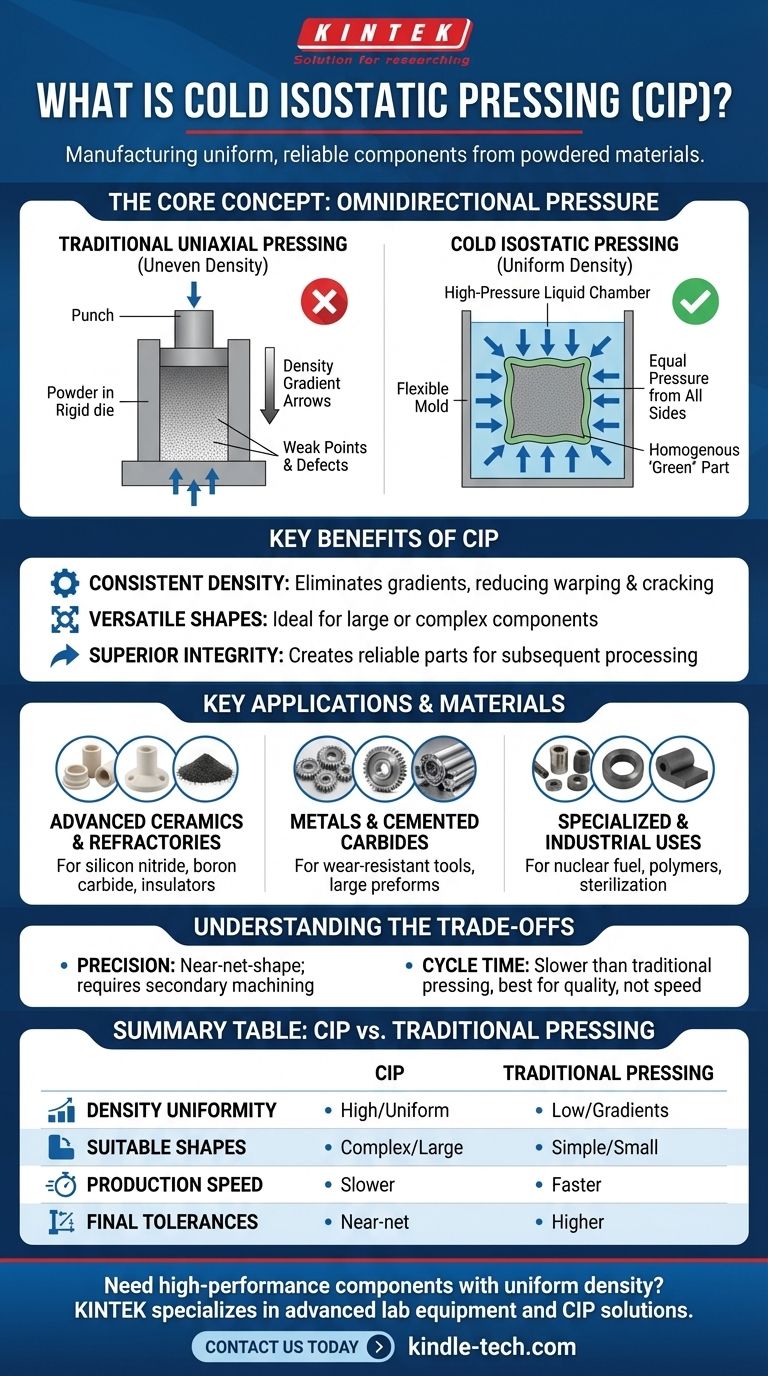

The central challenge in forming parts from powder is achieving uniform density; traditional pressing creates weak points that lead to defects. Cold Isostatic Pressing solves this by using fluid to apply equal pressure from all directions, producing a homogenous component that is far more reliable for subsequent machining or high-temperature sintering.

The Core Problem CIP Solves: Uniform Density

The true value of Cold Isostatic Pressing is best understood by comparing it to the most common alternative, uniaxial pressing.

The Limitation of Traditional Pressing

In traditional (uniaxial) pressing, a die is filled with powder and compacted by a punch moving in a single direction.

This creates significant friction between the powder particles and the die walls. As a result, the pressure is not distributed evenly.

The final part has density gradients, with the areas closest to the punch being much denser than those farther away. These inconsistencies can cause warping, cracking, and unpredictable shrinkage during the final sintering stage.

How Isostatic Pressure Creates Consistency

Cold Isostatic Pressing completely avoids this problem by immersing a flexible, sealed mold filled with powder into a high-pressure liquid chamber.

A pump pressurizes the fluid, which then transmits that pressure equally to every surface of the mold.

This omnidirectional pressure compacts the powder uniformly, eliminating the density gradients and internal stresses found in uniaxially pressed parts. The result is a homogenous "green" part with superior structural integrity, ready for final processing.

Key Applications and Materials

CIP's ability to create uniform green parts makes it indispensable for manufacturing high-performance components across numerous industries.

Advanced Ceramics and Refractories

This is a primary application for CIP. Materials like silicon carbide, silicon nitride, boron carbide, and electrical insulators are brittle and highly sensitive to internal defects.

The uniform density provided by CIP is critical to prevent the formation of micro-cracks that would lead to catastrophic failure in the final, sintered product.

Metals and Cemented Carbides

CIP is widely used to form parts from tool steel, high-melting-point metals, and cemented carbides.

It is particularly effective for creating large preforms for wear-resistant tools or components that are simply too big to fit into a conventional press.

Specialized and Industrial Uses

The versatility of the process extends to many other fields. Common applications include:

- Consolidating graphite, ferrites, and nuclear fuel.

- Forming parts from specialized polymer and resin powders.

- Densification of thermal spray coatings to remove porosity.

- High-pressure sterilization in the food and pharmaceutical industries.

Understanding the Trade-offs

While powerful, CIP is not a universal solution. Understanding its limitations is key to using it effectively.

Precision and Tolerances

Cold Isostatic Pressing is a near-net-shape process, but it is not a final-step manufacturing method.

The flexible mold does not provide the high dimensional accuracy of a rigid steel die. The resulting green parts almost always require secondary processing, such as machining or sintering, to meet final tolerance specifications.

Cycle Time and Throughput

The process of loading the mold, placing it in the pressure vessel, pressurizing, depressurizing, and unloading is inherently slower than the rapid cycle times of automated uniaxial presses.

For this reason, CIP is typically reserved for applications where part quality and uniform density are more critical than mass production speed.

Making the Right Choice for Your Goal

Selecting the correct powder compaction method depends entirely on the requirements of your final component.

- If your primary focus is creating large or complex shapes with high reliability: CIP is the superior choice for producing preforms with the uniform density needed to prevent defects during sintering.

- If your primary focus is high-volume production of simple, smaller shapes: Traditional uniaxial pressing is often faster, less complex, and more cost-effective.

- If your primary focus is achieving maximum final density in a single step: You may need to investigate Hot Isostatic Pressing (HIP), which combines high pressure with elevated temperatures.

By leveraging omnidirectional fluid pressure, Cold Isostatic Pressing provides a unique solution for creating high-quality components from powdered materials.

Summary Table:

| Aspect | Cold Isostatic Pressing (CIP) | Traditional Uniaxial Pressing |

|---|---|---|

| Density Uniformity | High - Uniform in all directions | Low - Density gradients exist |

| Suitable Shapes | Complex, large, or irregular shapes | Simple, smaller shapes |

| Production Speed | Slower cycle times | Faster, high-volume production |

| Final Tolerances | Near-net-shape, requires secondary machining | Higher dimensional accuracy |

| Key Advantage | Eliminates internal defects and weak points | Cost-effective for mass production |

Need to produce high-performance components with uniform density?

At KINTEK, we specialize in providing advanced lab equipment and consumables, including Cold Isostatic Pressing solutions, to help you create reliable, defect-free parts from advanced ceramics, metals, and carbides. Our expertise ensures your materials achieve the consistent density required for superior performance in demanding applications.

Contact us today to discuss how our CIP technology can enhance your manufacturing process and deliver the quality your lab demands.

Get in touch with our experts now!

Visual Guide

Related Products

- Electric Lab Cold Isostatic Press CIP Machine for Cold Isostatic Pressing

- Manual Cold Isostatic Pressing Machine CIP Pellet Press

- Automatic Lab Cold Isostatic Press CIP Machine Cold Isostatic Pressing

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Automatic High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

People Also Ask

- What is the dry bag process? A Guide to High-Speed Isostatic Pressing

- How does a cold isostatic press (CIP) facilitate LPSCl/LLZO interfaces? Unlock Superior Solid-State Battery Bonds

- How does a Cold Isostatic Press (CIP) contribute to the fabrication of HE-O-MIEC and LLZTO? Expert Densification Guide

- What temperature is cold isostatic pressing? A Guide to Room-Temperature Powder Compaction

- What is cold isostatic pressure? Achieve Uniform Density for Complex Powder Parts

- What is the pressure for cold isostatic pressing? Achieve Superior Density and Uniformity

- What products are made by isostatic pressing? Achieve Flawless, High-Performance Components

- Why is an isostatic press used for solid electrolyte pellets? Achieve Maximum Density for Accurate Ionic Conductivity