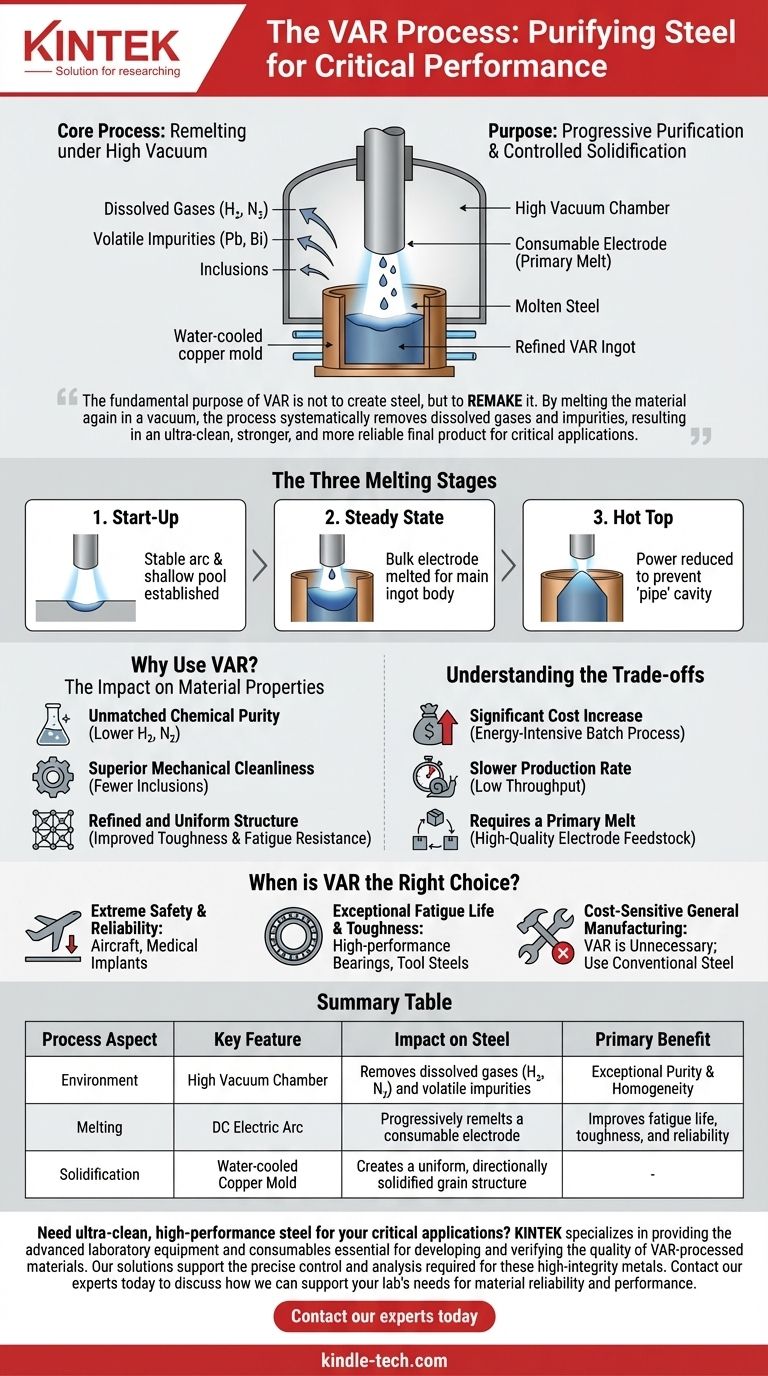

At its core, Vacuum Arc Remelting (VAR) is a secondary metallurgical process used to produce steel with exceptional purity and a highly refined internal structure. It is not a method for making steel from raw materials, but rather a purification step. The process involves taking a solid steel cylinder, known as a consumable electrode, and progressively remelting it under a high vacuum using an electric arc into a water-cooled copper mold.

The fundamental purpose of VAR is not to create steel, but to remake it. By melting the material again in a vacuum, the process systematically removes dissolved gases and impurities, resulting in an ultra-clean, stronger, and more reliable final product for critical applications.

The Mechanics of a Cleaner Melt

To understand the value of VAR, you must first understand its unique operational environment. Each step is deliberately designed to enhance material purity and structural integrity.

The Consumable Electrode

The process begins with a solid electrode of a specific steel chemistry. This electrode is typically produced through a primary melting process, such as in an Electric Arc Furnace (EAF) or via Vacuum Induction Melting (VIM).

The Vacuum Environment

The entire remelting operation occurs within a sealed chamber under a high vacuum. This is the most critical element of the process, as the vacuum actively pulls undesirable dissolved gases—especially hydrogen and nitrogen—out of the molten metal. It also causes volatile tramp elements like lead and bismuth to vaporize and be removed.

The Arc and Controlled Solidification

A DC electric current is used to strike an arc between the bottom of the electrode and a small amount of starter material in the base of a water-cooled copper crucible. The intense heat of the arc melts the tip of the electrode, causing molten steel to fall drop by drop into the crucible below.

This controlled, progressive melting and solidification from the bottom up creates a highly uniform and directionally aligned grain structure, minimizing chemical segregation.

The Three Melting Stages

The process is managed in three distinct phases to ensure a sound final ingot:

- Start-Up: A stable arc and a shallow molten pool are carefully established.

- Steady State: The bulk of the electrode is melted at a constant rate to build the main body of the ingot.

- Hot Top: The power is slowly reduced to control the solidification of the final molten metal at the top, preventing a central shrinkage cavity known as a "pipe."

Why Use VAR? The Impact on Material Properties

The tightly controlled VAR process yields distinct advantages that are impossible to achieve with conventional, large-scale steelmaking methods.

Unmatched Chemical Purity

By removing dissolved gases, VAR steel has significantly lower hydrogen content, which is a primary cause of internal cracking and embrittlement. The removal of other volatile impurities further enhances the material's integrity.

Superior Mechanical Cleanliness

During remelting, non-metallic inclusions (such as oxides and sulfides) have time to float to the top of the molten pool. This allows them to be isolated from the usable ingot, resulting in a "cleaner" steel with far fewer internal stress points where fatigue cracks can initiate.

Refined and Uniform Structure

The directional solidification process prevents the formation of coarse, non-uniform crystals. Instead, it creates a fine-grained, homogenous microstructure that directly improves the material's toughness, ductility, and fatigue resistance.

Understanding the Trade-offs

Despite its benefits, VAR is not a universal solution. Its targeted application is dictated by significant trade-offs.

Significant Cost Increase

VAR is an additional, highly energy-intensive batch process performed on already-made steel. This second melting step adds considerable cost to the final product compared to conventionally produced steel.

Slower Production Rate

Remelting an electrode is a slow, meticulous process. The throughput of a VAR furnace is a fraction of that of a primary steel mill, making it unsuitable for high-volume, commodity steel production.

Requires a Primary Melt

VAR is a secondary refining process, meaning it relies on a supply of high-quality electrodes. This adds a step to the manufacturing chain and requires careful control over the chemistry of the initial electrode.

When is VAR the Right Choice?

Choosing a VAR-processed material is a decision driven entirely by the performance demands of the final application.

- If your primary focus is extreme safety and reliability: VAR is non-negotiable for critical components like aircraft landing gear, turbine engine discs, or medical implants where material failure would be catastrophic.

- If your primary focus is exceptional fatigue life and toughness: VAR is the clear choice for high-performance bearings, specialized gears, and tool steels subjected to intense, cyclical stress.

- If your primary focus is cost-sensitive general construction or manufacturing: VAR is almost certainly unnecessary and uneconomical; conventional steelmaking processes are far more appropriate.

By understanding that VAR is a precision purification tool, you can specify it for applications where material integrity is the absolute priority.

Summary Table:

| Process Aspect | Key Feature | Impact on Steel |

|---|---|---|

| Environment | High Vacuum Chamber | Removes dissolved gases (H₂, N₂) and volatile impurities |

| Melting | DC Electric Arc | Progressively remelts a consumable electrode |

| Solidification | Water-cooled Copper Mold | Creates a uniform, directionally solidified grain structure |

| Primary Benefit | Exceptional Purity & Homogeneity | Improves fatigue life, toughness, and reliability |

Need ultra-clean, high-performance steel for your critical applications?

KINTEK specializes in providing the advanced laboratory equipment and consumables essential for developing and verifying the quality of VAR-processed materials. Our solutions support the precise control and analysis required for these high-integrity metals.

Contact our experts today to discuss how we can support your lab's needs for material reliability and performance.

Visual Guide

Related Products

- Vacuum Arc Induction Melting Furnace

- Vacuum Induction Melting Spinning System Arc Melting Furnace

- Vacuum Heat Treat Sintering Brazing Furnace

- Vacuum Heat Treat and Sintering Furnace with 9MPa Air Pressure

- Vacuum Heat Treat Furnace and Levitation Induction Melting Furnace

People Also Ask

- What is var in metals? A Guide to Vacuum Arc Remelting for Superior Alloys

- How does vacuum arc remelting work? Achieve Ultra-Clean, High-Performance Metal Alloys

- What is the overview of vacuum arc remelting? Achieve Ultra-Clean, High-Performance Alloys

- What is the benefit of vacuum arc remelting? Achieve Superior Metal Purity and Structural Integrity

- What is the process of vacuum arc remelting? Achieve Ultimate Purity for High-Performance Alloys